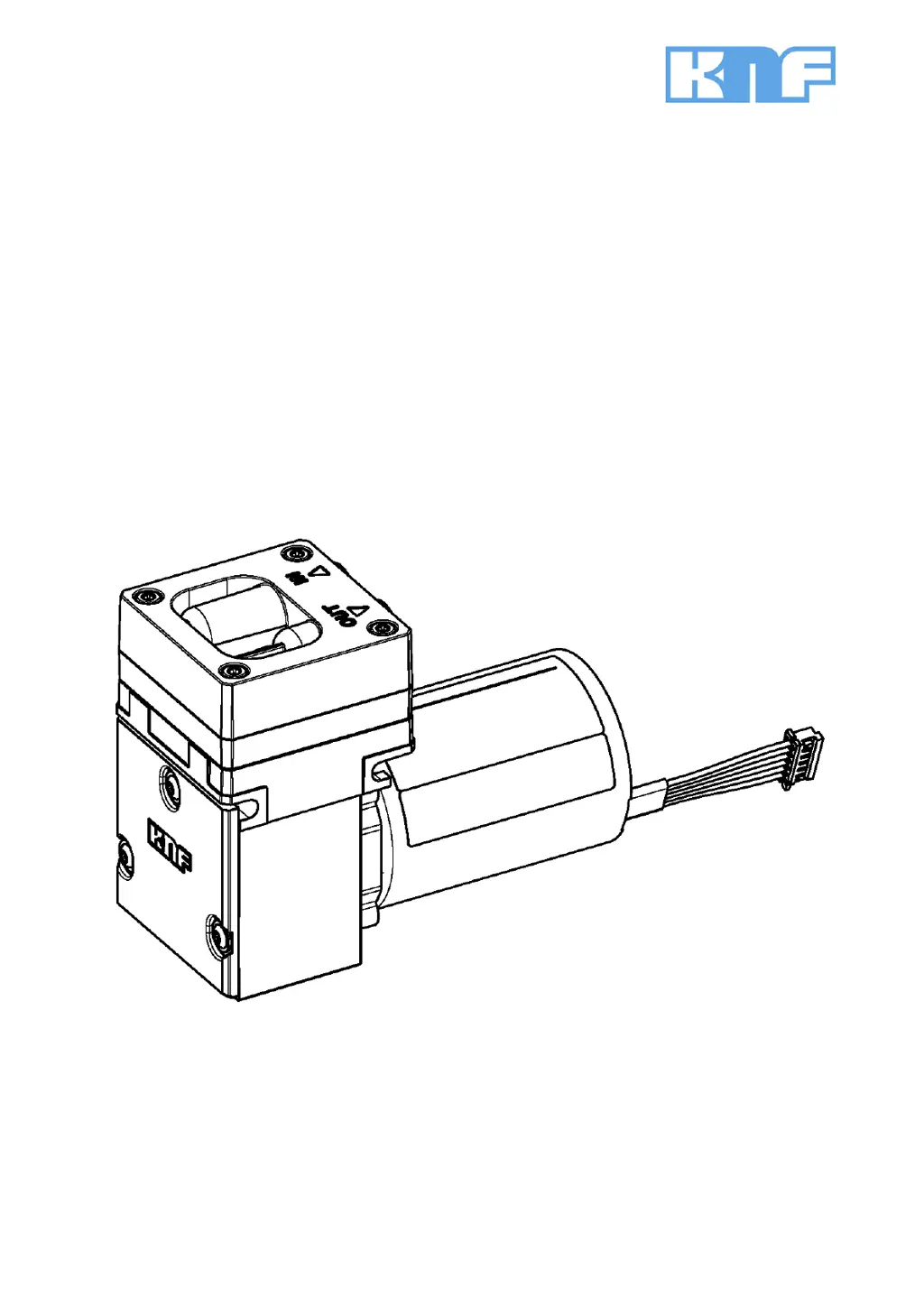

What to do if my KNF N96 is not delivering?

- MMargaret RodriguezAug 2, 2025

If your KNF Water Pump isn't delivering, first ensure it's properly connected to the electrical mains. Then, check your room fuse and switch it on if necessary. Blocked connections or lines can also cause this issue, so inspect and clear any blockages. Also, examine external valves and filters for obstructions. If condensate has collected in the pump head, separate the source and flush the pump with air. Make sure that the applied voltage does not exceed the value specified in Chapter 7.3 Electrical connection. Finally, worn or defective diaphragms and valves can prevent delivery; consider replacing them.