TP-6079 3/0020 Section 5 Generator Troubleshooting

5.4 Stator

The stator consists of a series of coils of wire laid in a

laminated steel frame. The stator leads supply voltage

to the AC load and exciter regulator. See Figure 5-7 for

coil lead description.

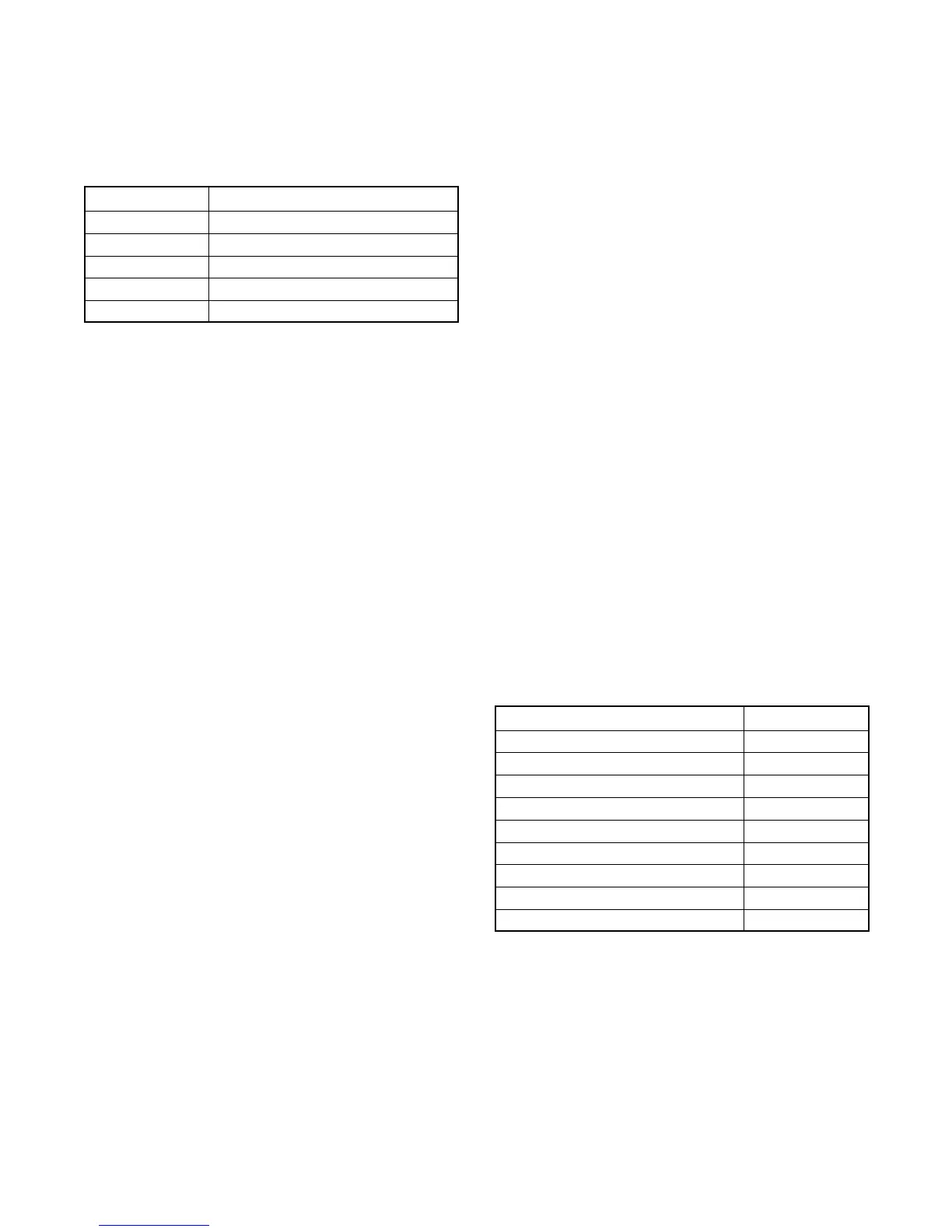

Stator Leads Description

1--2 Output coil

3--4 Output coil

33--44 Control wires from 3 and 4

55--33 Voltage regulator power source

B1--B2 Controller power source

Figure 5-7 Stator Coil Lead Description

Before testing the stator, inspect it for heat discoloration

and visible damage to the exposed coil windings and

varnished areas of the frame laminations. Be sure the

stator is securely fastened in the stator housing.

The stator produces electrical output (AC) as the

magnetized main field rotates within the stator windings.

Test the condition of the stator according to the following

procedure.

Leads 1, 2, 3, and 4 are the generator output leads.

Leads 33, 44, and 55 are the voltage regulator supply

and sensing leads. The output of leads B1 and B2 is the

control voltage for the controller.

Stator Test Procedure:

1. Place the generator start/stop switch in the STOP

position.

2. Disconnect the generator set engine starting

battery, negative (--) lead first.

3. Check the generator output lead connections. See

Section 8, Reconnection and Wiring Diagrams.

4. Disconnect all of the stator leads to isolate the

windings. To check the stator continuity, set the

ohmmeter on the R x 1 scale. Check the stator

continuity by connecting the meter leads to the

stator leads as shown in Figure 5-8. Perform the

stator tests on all of the stator windings.

Note: When taking an ohmmeter reading using

lead 55, make the connection prior to the

in-line fuse.

5. Check the cold resistance of the stator windings by

connecting the meter leads to the stator leads 1-4,

2-5, 3-6, etc. See Section 1, Specifications, for the

stator resistance values.

6. Perform a megohmmeter test on the stator as

described in step 7.

Note: Consider the stator functional if the

resistance reading (continuity) is low and

there is no evidence of shorted windings

(heat discoloration).

Note: The stator resistance varies directly with

increased temperature.

If the stator readings vary considerably during the

previous checks, repair or replace the stator.

7. Check the stator for a grounded condition using a

megohmmeter. Apply 500 volts DC to any stator

lead from each winding and the stator frame.

Follow the instructions of the megohmmeter

manufacturer when performing this test. Repeat

the test on the other leads until all of the stator

windings have been tested. A reading of

approximately 1.5 megohms and higher indicates

the stator is functional. A reading of less than

approximately 1.5 megohms indicates

deterioration of the winding insulation and possible

current flow to ground; if so, replace the stator.

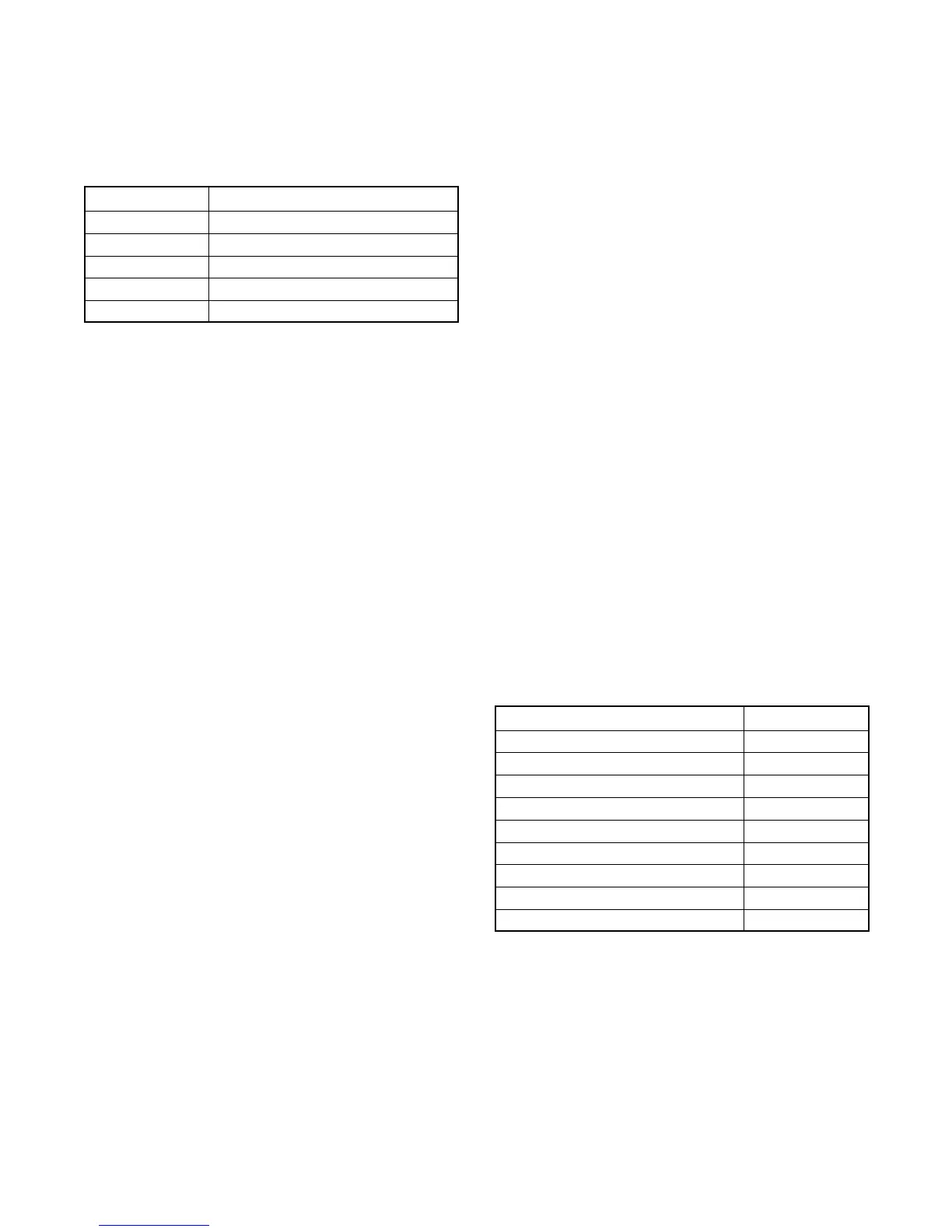

Between Leads Continuity

1 and 2 Yes

3 and 4 Yes

55 and 66 Yes

B1 and B2 Yes

1 and 3, 4, 33, 44, 55 No

1 and 55, B1 and B2 No

4 and B1 and B2 No

55 and B1 and B2 No

Any stator lead and ground No

Figure 5-8 Stator Continuity

Loading...

Loading...