9.2

Section 9

Inspection and Reconditioning

Inspect the crankpin for score marks or metallic

pickup. Slight score marks can be cleaned with crocus

cloth soaked in oil. If wear limits, as stated in Section

1, Specifications and Tolerances are exceeded, it will

be necessary to replace the cranksha.

Crankcase

Inspection and Service

Check all gasket surfaces to make sure they are free of

gasket fragments. Gasket surfaces must also be free of

deep scratches or nicks.

Check the cylinder bore for scoring. In severe cases,

unburned fuel can cause scuffing and scoring of the

cylinder wall. It washes the necessary lubricating

oils off the piston and cylinder wall. As raw fuel

seeps down the cylinder wall, the piston rings make

metal to metal contact with the wall. Scoring of the

cylinder wall can also be caused by localized hot

spots resulting from blocked cooling fins or from

inadequate or contaminated lubrication.

If the cylinder bore is badly scored, excessively worn,

tapered, or out-of-round, resizing is necessary. Use an

inside micrometer to determine the amount of wear

(refer to Section 1, Specifications and Tolerances),

A 0.25 mm (0.010 in.) oversize piston is available if

resizing is selected. Initially, resize using a boring

bar, then use the following procedures for honing the

cylinder.

Honing

While most commercially available cylinder hones

can be used with either portable drills or drill presses,

the use of a low speed drill press is preferred as it

facilitates more accurate alignment of the bore in

relation to the cranksha crossbore. Honing is best

accomplished at a drill speed of about 250 RPM and

60 strokes per minute. Aer installing coarse stones in

hone, proceed as follows:

1. Lower hone into bore and aer centering, adjust

so that the stones are in contact with the cylinder

wall. Use of a commercial cuing-cooling agent is

recommended.

2. With the lower edge of each stone positioned

even with the lowest edge of the bore, start drill

and honing process. Move the hone up and down

while resizing to prevent the formation of cuing

ridges. Check the size frequently.

NOTE: Kohler pistons are custom-machined to

exacting tolerances. When over-sizing a

cylinder, it should be machined exactly

0.25 mm (0.010 in.) over the new diameter

(Section 1, Specifications and Tolerances). The

oversize Kohler replacement piston will then

fit correctly.

3. When the bore is within 0.064 mm (0.0025 in.) of

the desired size, remove the coarse stones and

replace them with burnishing stones. Continue

with the burnishing stones until the bore is

within 0.013 mm (0.0005 in.) of the desired size

and then use finish stones (220-280 grit) and

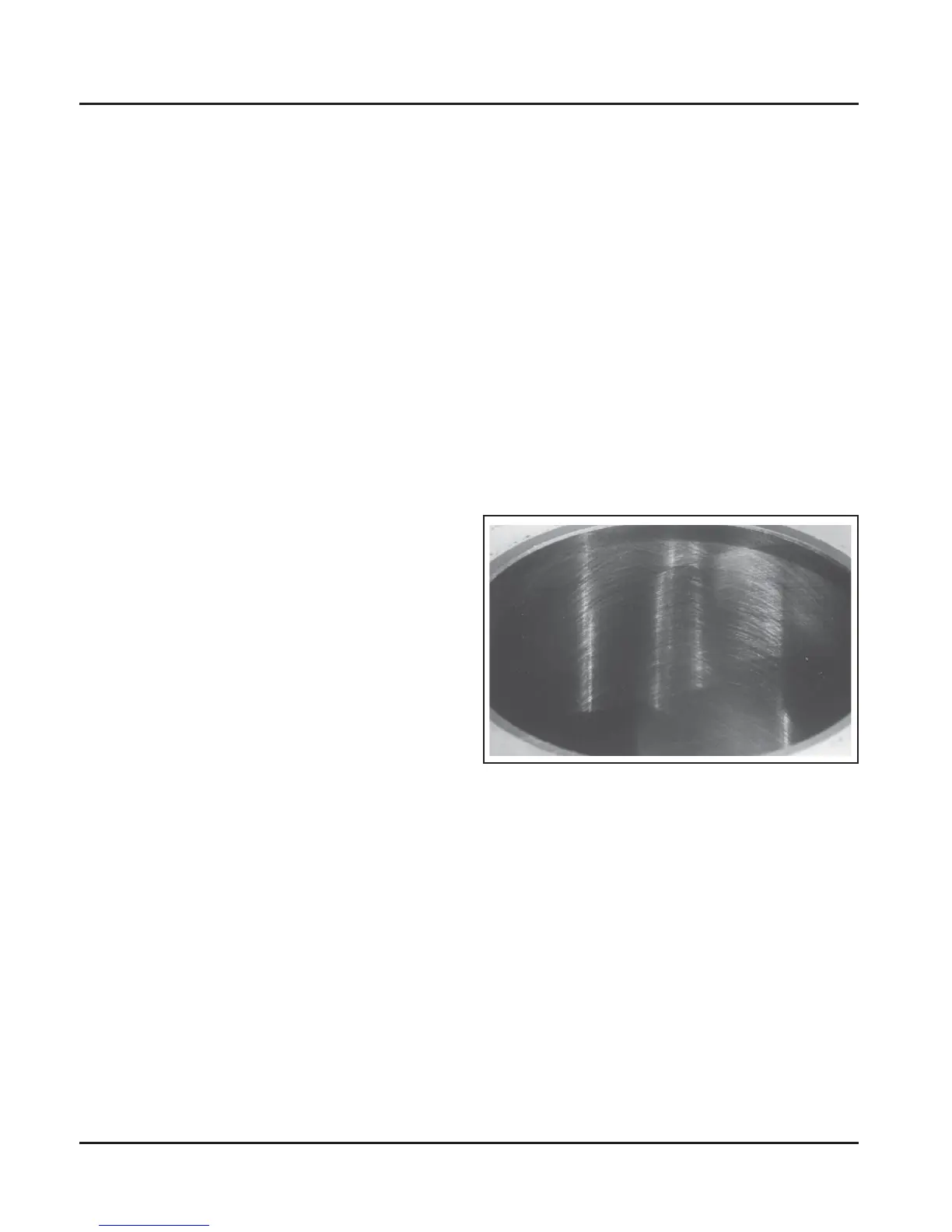

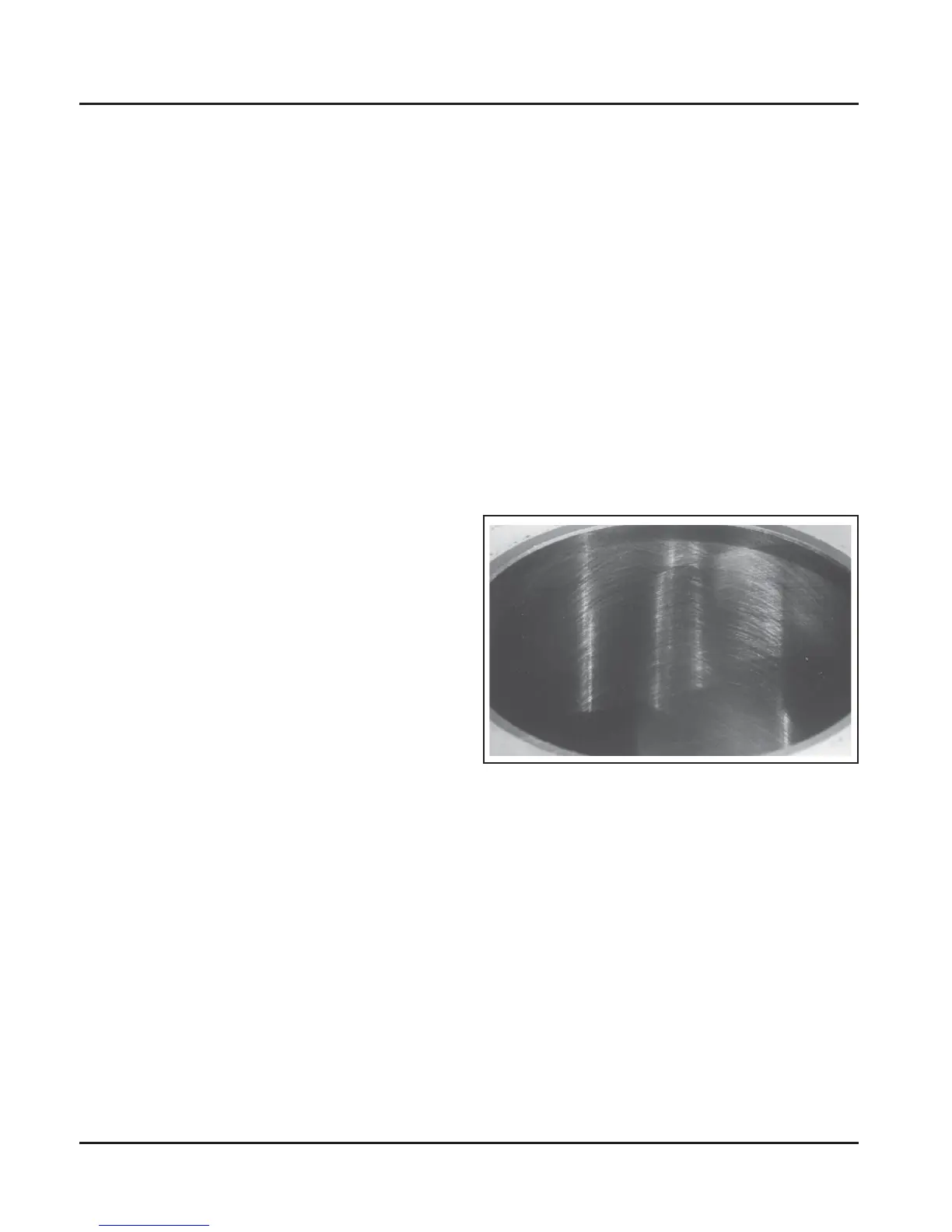

polish the bore to its final size. A crosshatch

should be observed if honing is done correctly.

The crosshatch should intersect at approximately

23°-33° off the horizontal. Too flat an angle could

cause the rings to skip and wear excessively,

and too steep an angle will result in high oil

consumption. See Figure 9-1.

Figure 9-1. Cylinder Bore Crosshatch After

Honing.

4. Aer resizing, check the bore for roundness,

taper, and size. Use an inside micrometer,

telescoping gauge, or bore gauge to take

measurements. The measurements should be

taken at three locations in the cylinder – at the

top, middle, and boom. Two measurements

should be taken (perpendicular to each other) at

each of the three locations.

Clean Cylinder Bore After Honing

Proper cleaning of the cylinder walls following boring

and/or honing is very critical to a successful overhaul.

Machining grit le in the cylinder bore can destroy

an engine in less than one hour of operation aer a

rebuild.

Loading...

Loading...