4 — PROGRAMMABLE PARAMETERS

Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022 Return to TOC

pg. 98

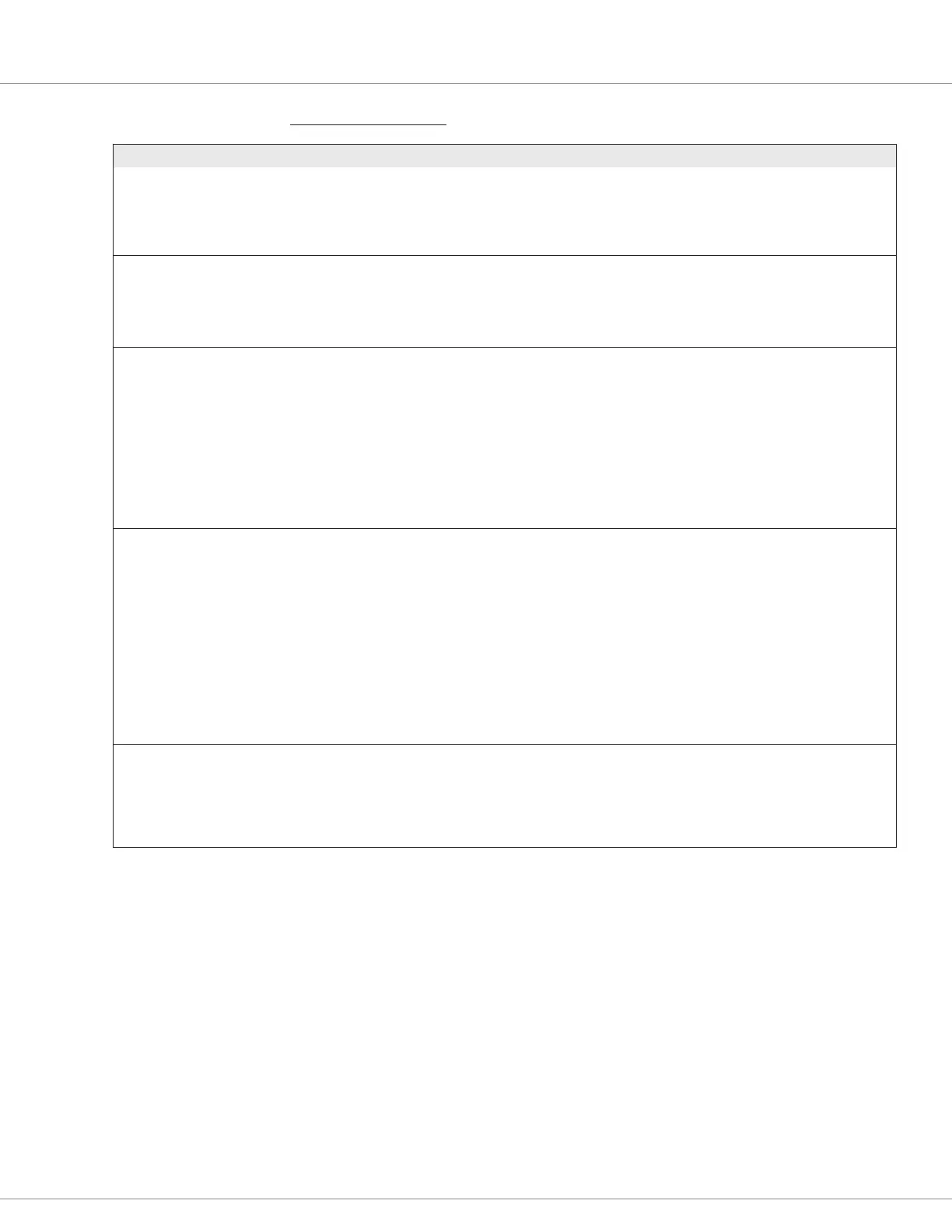

APPLICATION SETUP — MAX SPEED SUPERVISION MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

Present Max Speed Limit

Current_Max_Speed_Limit

0x37AB 0x00

–2147483648 –

2147483647

–2147483648 –

2147483647

Read Only

rpm

A monitor variable, in rpm, that shows the present (real time) Max

Speed Limit accounting for the Max Speed Limit percent and Max

Speed Limit Slew Rate time parameters (below).

This variable is useful for setting up the Max Speed

Supervision parameters.

Max Speed Limit Timer

Max_Speed_Limit_Timer

0x37AC 0x00

–2147484.00 –

2147484.00

–2147483648 –

2147483647

Read Only

Seconds

The timer associated with the Max Speed Time Limit

parameter (below).

e.g., 0.01 – 10.0s

This variable is useful for setting up the Max Speed

Supervision parameters.

Max Speed Limit

Max_Speed_Limit

0x37A7 0x00

0.0 – 500.0 %

0 – 5000

25.0 % The Max Speed Supervision parameters detect conditions where

the speed limiting function is no longer following the maximum

speed limit of the vehicle. This parameter denes the percent over

the programmed Max Speed parameter before the Speed Limit

Supervision fault is checked and contributes to set the Speed

Limit Supervision fault.

This set of Max Speed Supervision parameters operates

independently from the normal motor control to ensure that

motor speed remains at a safe level for typically multi-mode

(e.g., elevated load travel) speeds. Note: Motor rpm is the basis of

vehicle speed.

Max Speed Limit Slew Rate

Max_Speed_Limit_Slew_Rate

0x37A8 0x00

0.1 – 60.0 s

100 – 6000

20.0 Sec This parameter denes a deceleration rate for the current Max

Speed Limit. The rate denition is the Typical_Max_Speed (RPM)/

Max_Speed_Limit_Slew_Rate.

In the event that the Max Speed decreases, the Max Speed Limit

will slew towards the new target limit at this rate. This parameter

should be set signicantly longer than the Max_Speed_Decel_

SpdM parameter to avoid false trips when adjusting accel and

decel rates. Conversely, if the Max Speed increases, the limit

will immediately step to the new target to avoid unnecessary

complications with Max_Speed_Accel_SpdM parameter.

Usage example: When the Max Speed Limit is changed in a multi-

mode event (e.g., reduced speed with elevated forks or load),

slows the vehicle in a dened decel rate.

Max Speed Time Limit

Max_Speed_Time_Limit

0x37A9 0x00

0.1 – 10.0 s

100 – 10000

5.0 Sec Controls the maximum time of the up/down counter for max speed

supervision. If the Max Speed Limit is exceeded, the timer counts

up, otherwise it counts down. If the timer reaches this parameter’s

time (setting), the Speed Limit Supervision fault is set.

(See the Max Speed Limit Timer and the Max Speed Limit

parameters, above.)

Loading...

Loading...