To service normal capacity type oil bath air cleaners, remove wing nut and remove air cleaner

components as a unit. Use the following procedure for cleaning.

1. Remove cover, lift element out of howl, drain dirty oil from bowl.

2.

Thoroughly wash cover and bowl in clean solvent.

Swish element in solvent, allow element

to drip dry.

DO

NOT

dry with air hose as this can ruin filtering material in this type of

cleaner.

Lightly re

-

oil element after cleaning with same type of oil as used in engine.

3.

Inspect air horn, filter bowl and cover gaskets. Replace gaskets if badly grooved or

cracked.

4.

Install gasket then

lace

cleaned filter bowl on air horn.

Add oil (same grade and weight as

engine oil) to

OIL

LEVEL

mark stamped on filter bowl.

5.

Reinstall element in bowl, position cover, place copper washer (when used) then secure

with wing nut

-

-

firmly tighten with fingers only.

6.

Check to make sure cleaner is properly installed so that no unfiltered air can enter

carburetor.

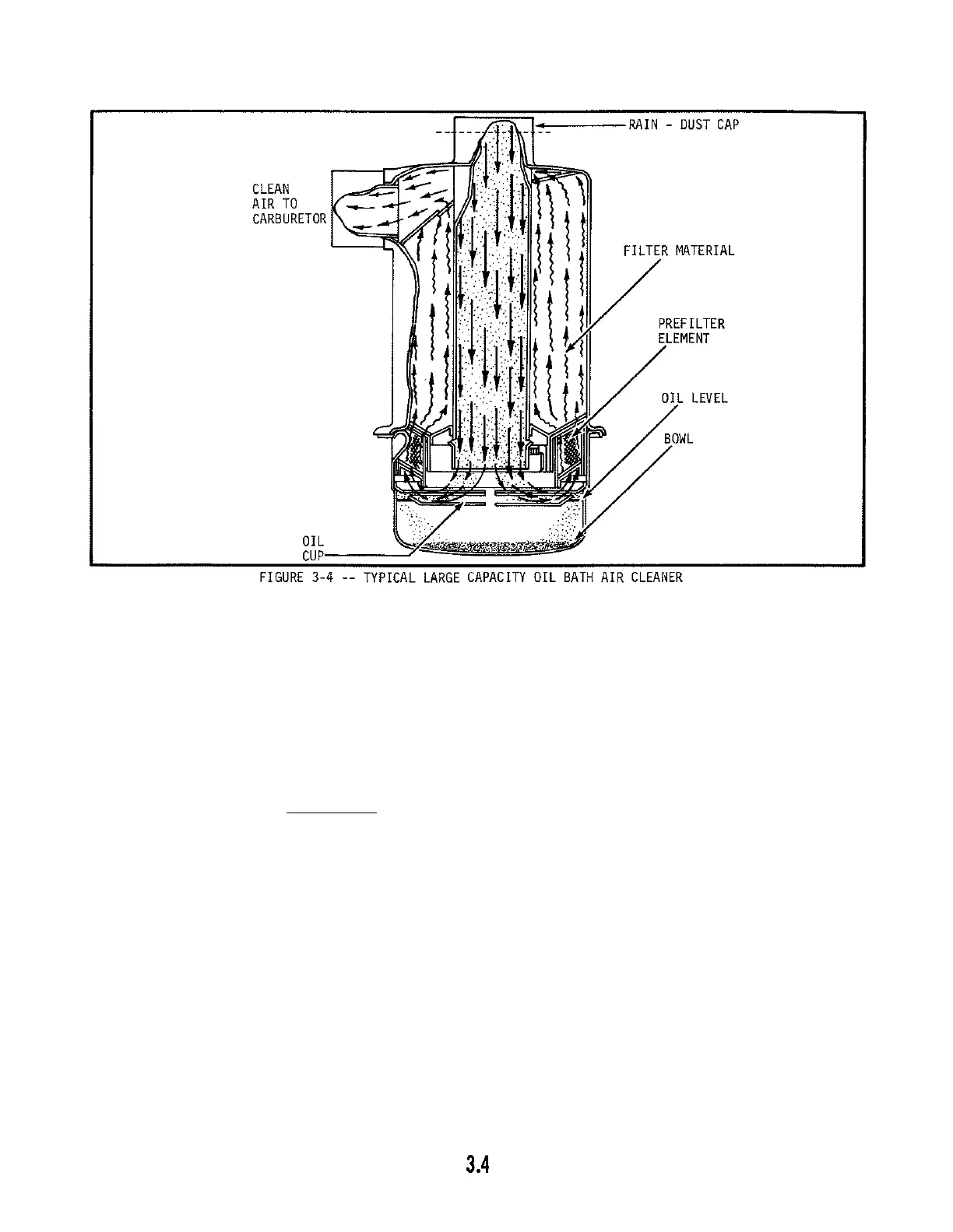

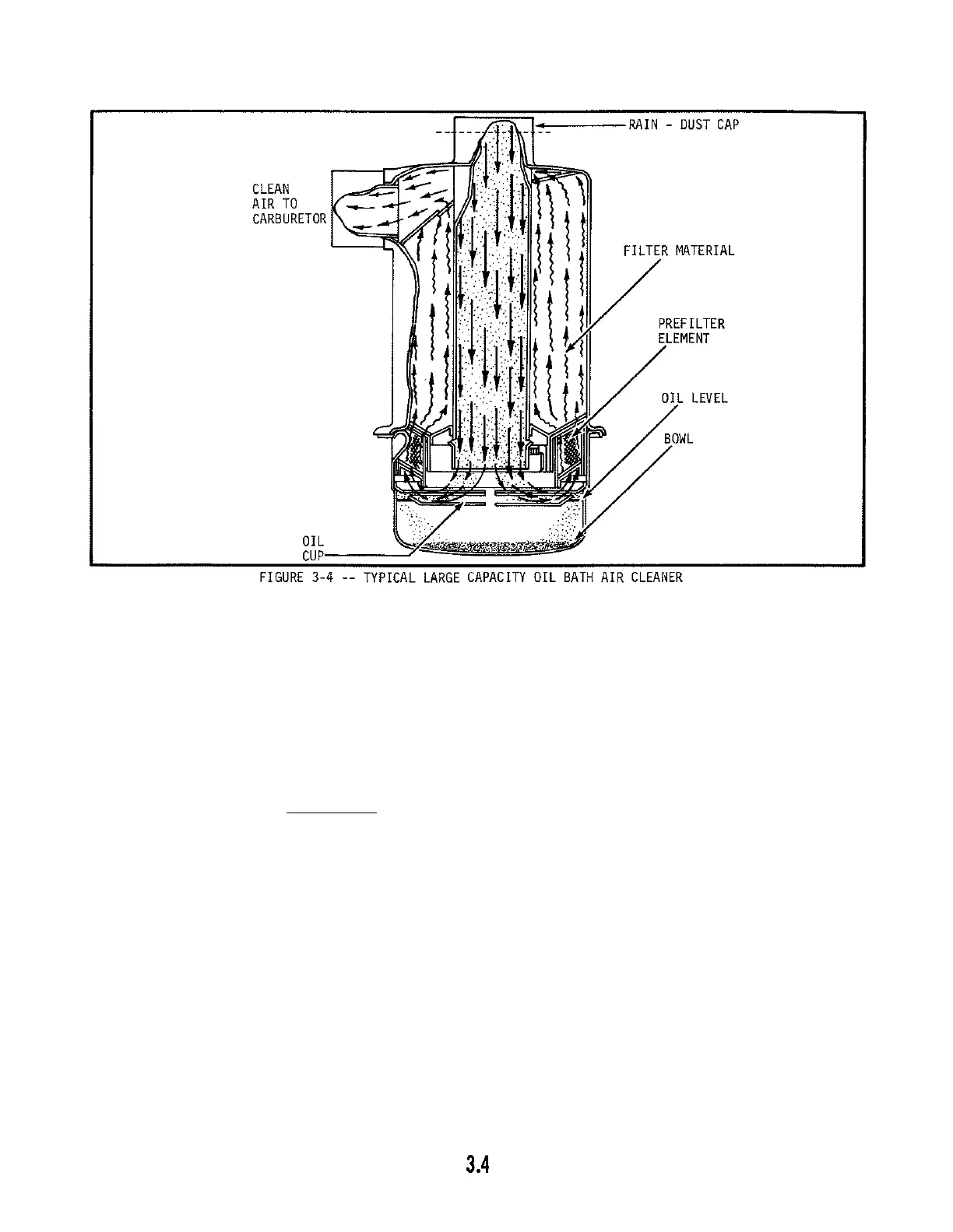

Servicing of the large capacity type oil bath is essentially the same as that stated for the normal

capacity type cleaners. The main difference is that the bowl is removed

from the bottom of the unit.

To remove, unfasten clamps or, if clamps are not used,

twist bowl until it is free of the locking tabs.

Service large capacity units as follows:

1.

After removing bowl, empty old oil and clean out sediment.

2.

Thoroughly clean disc and bowl.

If prefilter element is used, press element upward, then

twist to left until locking tabs line up with vertical slots then pull downward to remove.

Swish prefilter in clean solvent.

Allow to drip dry.

3.

After installing serviced prefilter (when used), add clean oil of same type used in engine

to level indicated in bowl.

Place disc in bowl and reinstall bowl cleaner body.

Loading...

Loading...