TURNS OPEN

FIGURE

-

-

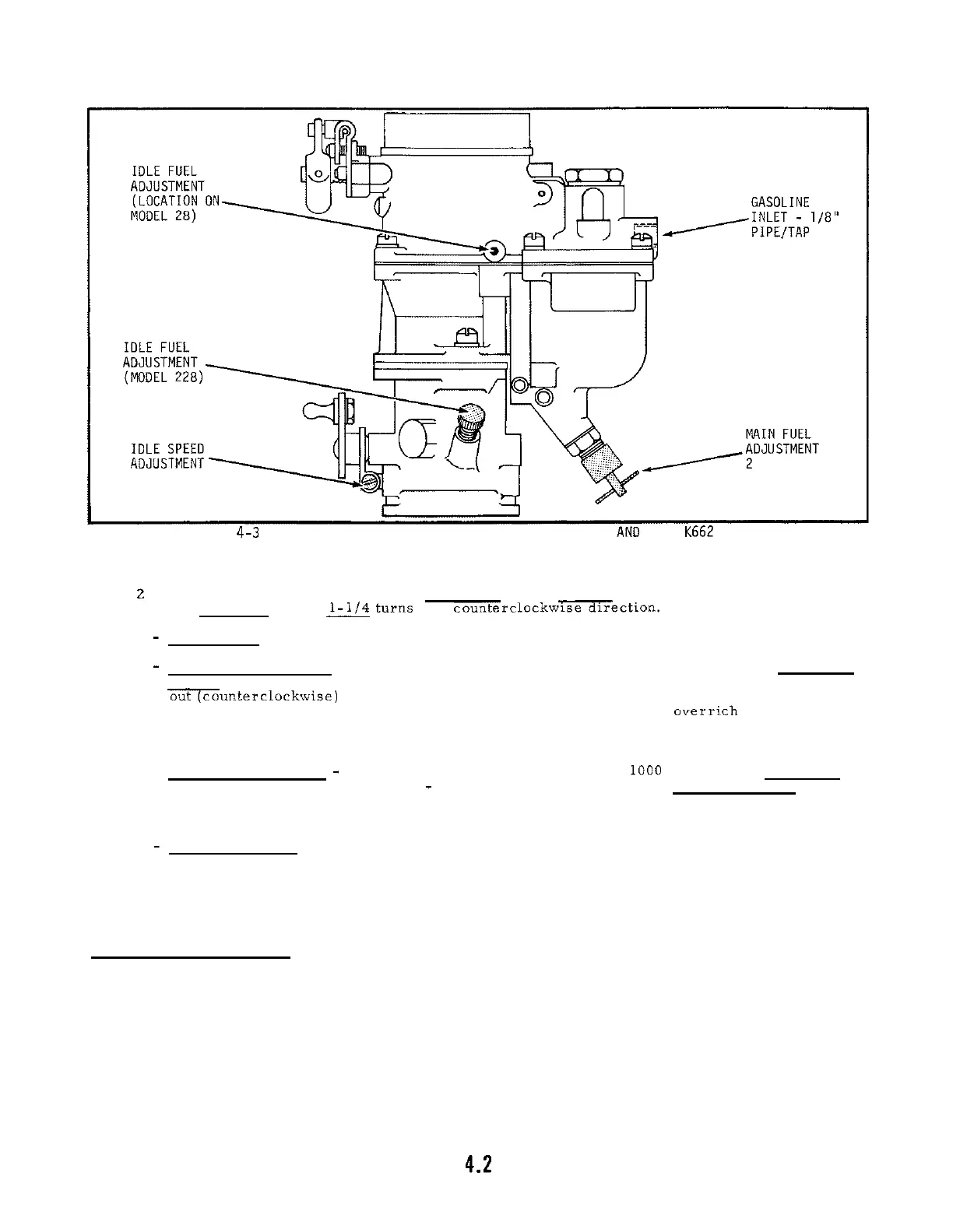

ADJUSTMENTS. DOWNDRAFT CARBURETOR MODELS

28

AND

228,

K662

ENGINES

STEP

2

-

Far preliminary adjustment, turn Main Fuel needle

3

turns in a counterclockwise direction,

turn Idle Fuel needle

1-

turns in a counterclockw~ection.

STEP

3

-

Start engine and operate at normal speed until normal operating temperatures are reached.

STEP

4

-

Main Fuel Adjustment

-

With engine operating at full throttle and full load, turn Main Fuel

Needle in (clockwise) until engine slows down (lean),

note position of screw, then turn needle

~unterclockwise) until engine regains speed and then again slows down (overrich).

Turn needle back in until it is positioned halfway between lean and

averrich settings.

If

adjusted properly, the engine should accelerate smoothly and operate with steady governor

action.

STEP

5

-

Idle Fuel Adjustment

-

Operate engine at idle speed of about 1000 RPM (adjust Idle Speed

screw until this speed is attained

-

check with tachometer).

Turn Idle Fuel Needle in

(clockwise) until engine slows down and idles rough then turn screw out until engine speeds

up and idles smoothly at the desired idle speed.

STEP

6

-

Final Adjustment

-

Since main fuel and idle fuel adjustment have some effect on each other,

recheck engine and make final adjustments as necessary to achieve smoothest operation.

NOTE:

If the preceding steps do not remedy problems attributed to carburetor, carburetor recon

-

ditioning may be necessary.

Carburetor Reconditioning: Hard starting, loss of power and rough idle are some of the problems that

can be attributed to improper adjustment or dirt, gum or varnish deposits within the carburetor.

If a

problem still exists after carburetor is readjusted, the carburetor should be disassembled and thor

-

oughly cleaned. This should also be done as a regular pre

-

season service after engine has been

stored for a considerable length of time.

All parts should be cleaned in solvent.

Gum is easily removed with alcohol or acetone solvent.

Be sure carbon deposits are removed from bore especially in area where throttle plate seats in cast

-

in

g

. Blow out all passages with compressed air.

DO NOT use wire brush or drill to clean out jets.

Replace all worn and damaged parts.

Always use new gaskets.

Carburetor repair kits are available

for most carburetors

--

kits include bowl nut gaskets (when required) howl ring gasket, float pin, bowl

baffle gasket, and fuel inlet needle and seat.

Loading...

Loading...