DISTRIBUTOR MAGNETO (WICO

XHG-2)

After every 500 hours of operation, remove distributor (end)

cap. Lubricate cam wick with Rjrcon grease, then check condition of breaker contacts.

If

dirty, clean

with lacquer thinner and coarse cloth. If slight amount of pitting and metal transfer is noted, dress

contacts with either a small tungsten file or a fine stone.

Contact point gap must be readjusted when

-

ever contacts are replaced or serviced.

Use

following procedure to adjust gap:

1. Turn engine over

by

hand until contact points are wide open (at highest point on cam).

2.

Loosen two clamp screws slightly so that contact plate can be moved.

3.

Insert blade of screwdriver in adjusting slot and move contact plate until .015" maximum

clearance is measured (feeler gauge) between contacts.

Securely tighten clamp screws

after adjustment.

Replace contact points if badly worn or pitted. Replace as a set

--

do not replace only one contact.

Replace as follows:

1.

Remove distributor gear screw and gear.

2.

To remove breaker arm, remove spring clamp screw, arm lock and washer then slip arm

off pivot. Discard old breaker arm.

3.

Breaker plate is removed after spacer washer and two clamp screws are removed.

Discard old breaker plate.

4.

Reverse procedure to install new breaker plate and arm (which include new contacts) then

adjust contact point gap per previous instructions. Remove and discard old cam wick and

replace with new wick, lubricating with Rycon grease.

Magnetos are timed to the engine in the factory and

retiming should not be necessary unless the

magneto has been removed for reconditioning or some other reason. Magnetos should be reconditioned

only at qualified magneto repair stations since special tools and test instruments are required. If

magneto has been removed, it must be

retimed to engine as follows:

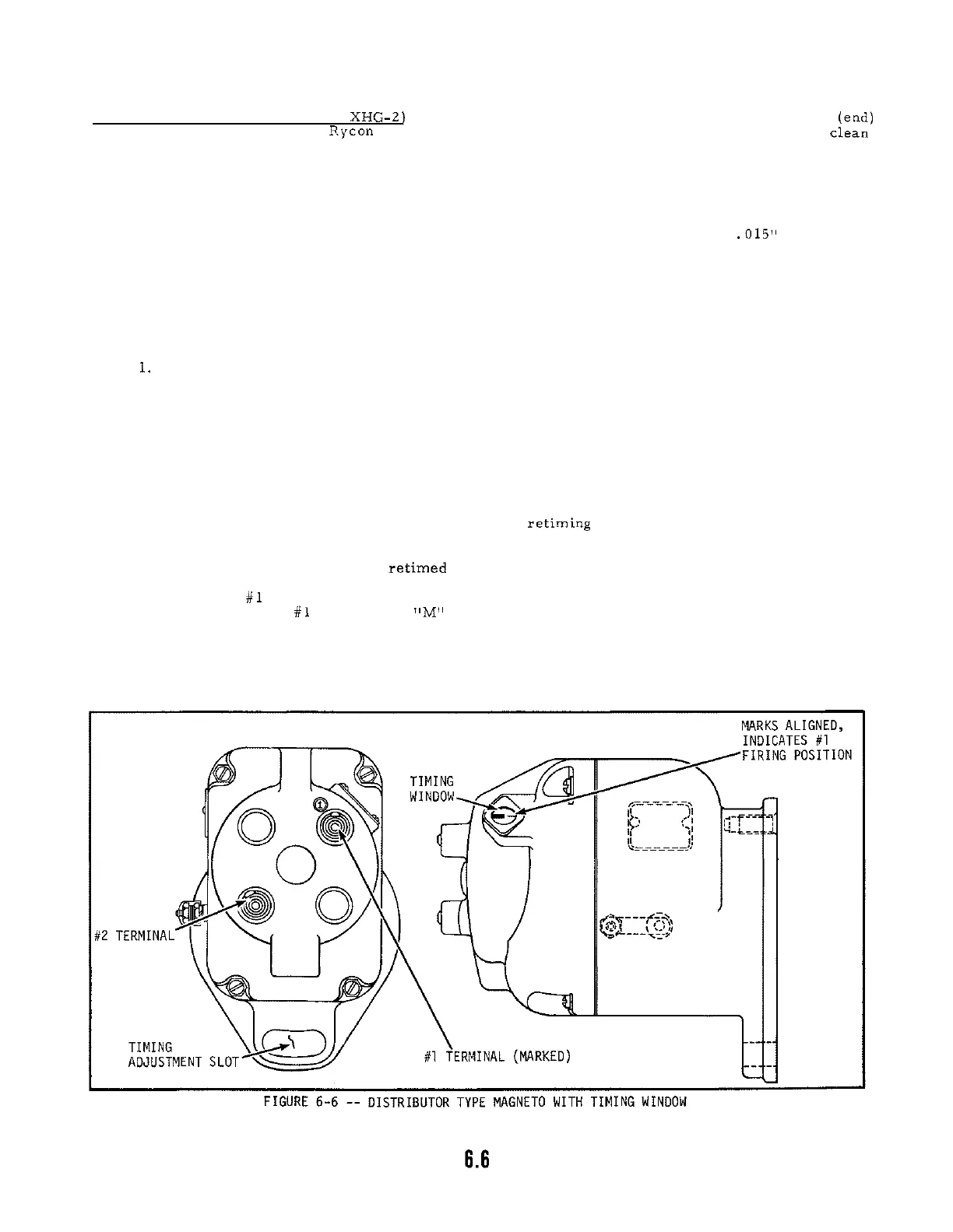

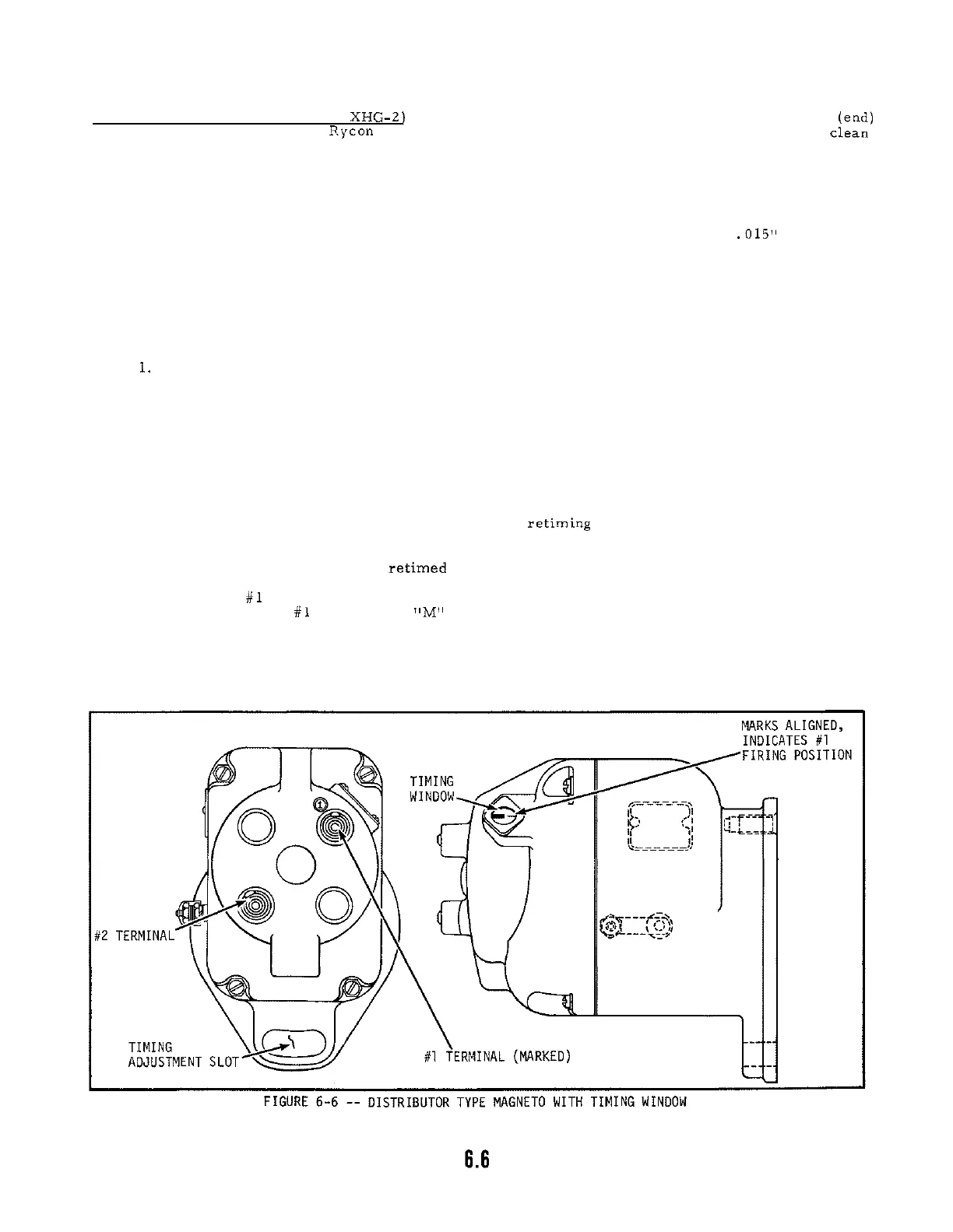

1.

Remove

#1 spark plug (cylinder closest to flywheel), turn engine over by hand until com

-

pression is on #1 cylinder and

"M"

mark on flywheel is centered in timing sight hole.

2.

Turn magneto gear counter

-

clockwise until white mark appears in sight window on distribu

-

tor or end cap. When mark appears, gear should hold in this position.

Loading...

Loading...