Precautions: In the event of a

"

false start

"

(engine gets up sufficient speed to disengage starter but

fails to continue running), the engine must be com

p

letel

y

stopped before another starting attempt is

made

--

if the flywheel is still rotating, the drive

ini ion

and ring gear will clash and almost certainl

y

be damaged.

Also

llmit

cranking (continuous)

to

a

period of 10 seconds to prevent overheating

of

the starter.

If

cranked for

10

seconds, starter should

not

be operated

again

for

60

seconds to allow time for suffi

cient coollng.

Service:

Most starters are pre

-

lubricated during assembly and do not require further lubrication until

disassembled for overhaul or other reasons. Some earlier model starters on the

K662

have hinged

oiler cups

-

-

these should be lubricated every 300 hours with

8

-

10 drops of medium grade engine oil.

The condition of brushes and commutator should be checked occasionally.

Replace brushes that

are unevenly worn or if excessively worn.

Brushes must slide freely in holders. Replace springs if

discolored (blue) from overheating.

If

commutator is dirty, clean with coarse cloth. If extremely

dirty, polish with

#OO sandpaper or commutator stone

-

-

do not use emery cloth.

If commutator

is

grooved or mica insulation is high, the armature shouldbemoved for reconditioning.

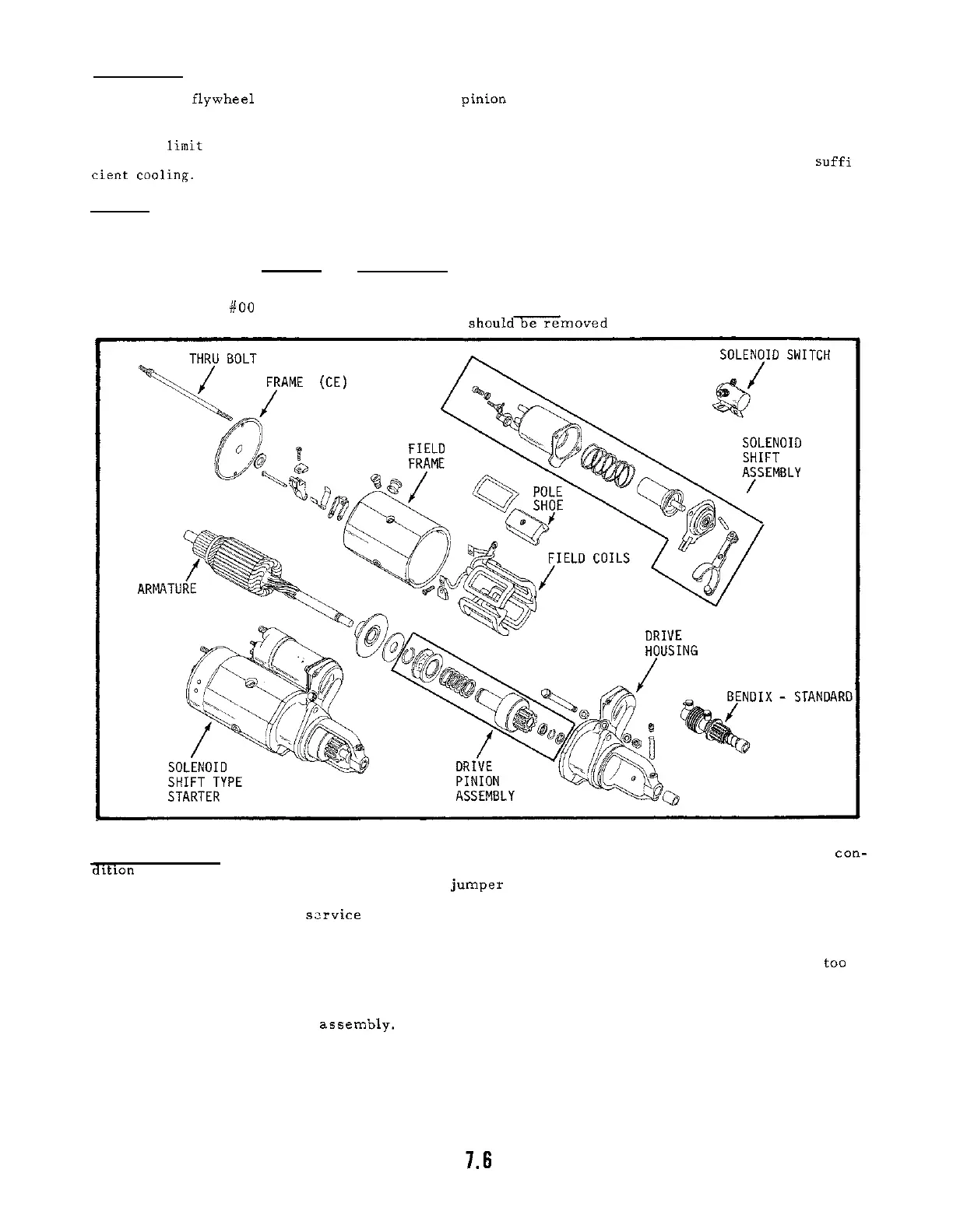

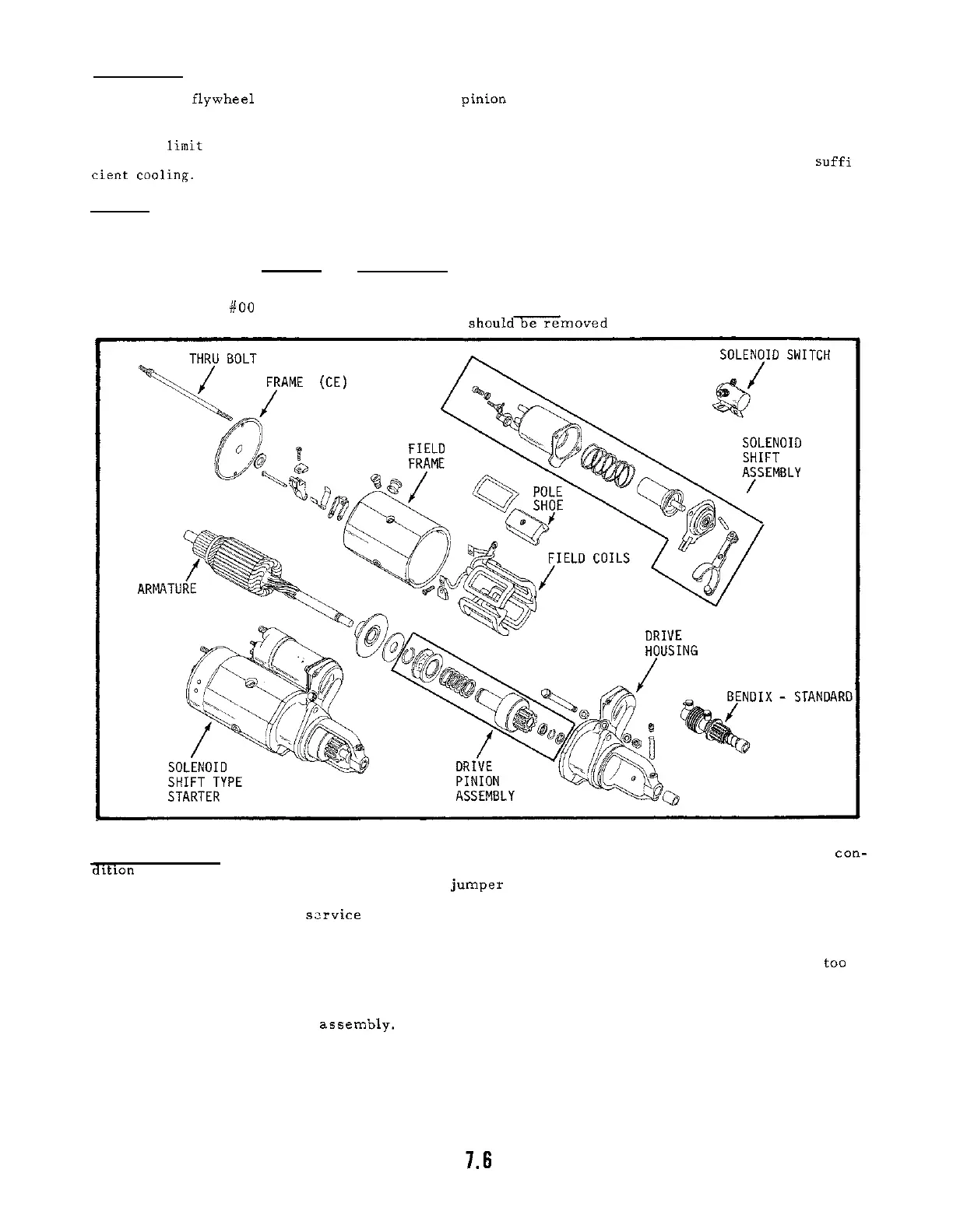

FIGURE

7

-

7

-

-

K662

STARTING MOTORS

-

EXPLODED VIEW

Trouble Analysis:

If

starter fails to energize,

first check wiring, starting switch or solenoid and

con-

F~tion of battery. Clean

or

replace badly corroded or dirty contacts

--

replace wires if frayed or

cracked.

Bypass start switch or solenoid with

jumper wire

-

-

if starter cranks normally, replace defec

tive switch or solenoid.

If starter turns too slowly and battery

is

in good condition, check for dirty

brushes or commutator and

s-rvice if needed.

If starter turns too slowly after brushes and commutator are checked, remove starter from

engine and check armature for binding. Armature should turn freely

--

if not, the cause could be too

little end play or improperly lubricated or badly worn sleeve bearings.

If starter spins without engaging (applies to Bendix type only),

the cause may be

a

dirty or

improperly lubricated Bendix

assembly. Do not dip drive in cleaning solution as this could damage

clutch. Brush solution on spline, wipe dry then apply dry spray type lubricant. Replace Bendix

assembly if pinion or splined sleeve is damaged.

If the

K482

type Bendix is moved into the extended

or engaged position while being cleaned, it will lock in this position

-

-

do not try to force it back into

the retracted position.

K482

starter can he installed on engine with pinion in engaged or disengaged

position.

Loading...

Loading...