it facilitates more accurate alignment of the bore in relation to the crankshaft crossbore.

Reboring is best accomplished at drill speed of about 600 RPM.

After installing coarse

stones in hone, proceed as follows:

STEP

1

-

Lower hone into bore and after centering, adjust so that stones are in contact

with walls.

Diesel fuel oil or kerosene can be applied to the stones as

a

cutting-

cooling agent.

STEP 2

-

With the lower edge of each stone positioned even with the lowest edge of the bore,

start drill and honing process. Move hone up and down while

reboring to prevent

formation of cutting ridges. Check size frequently.

STEP 3

-

When bore is within

.

0025

"

of desired size, remove coarse stones and replace

with burnishing stones.

Continue with burnishing stones until within

.0005" of

desired size then use finish stones and polish to final size.

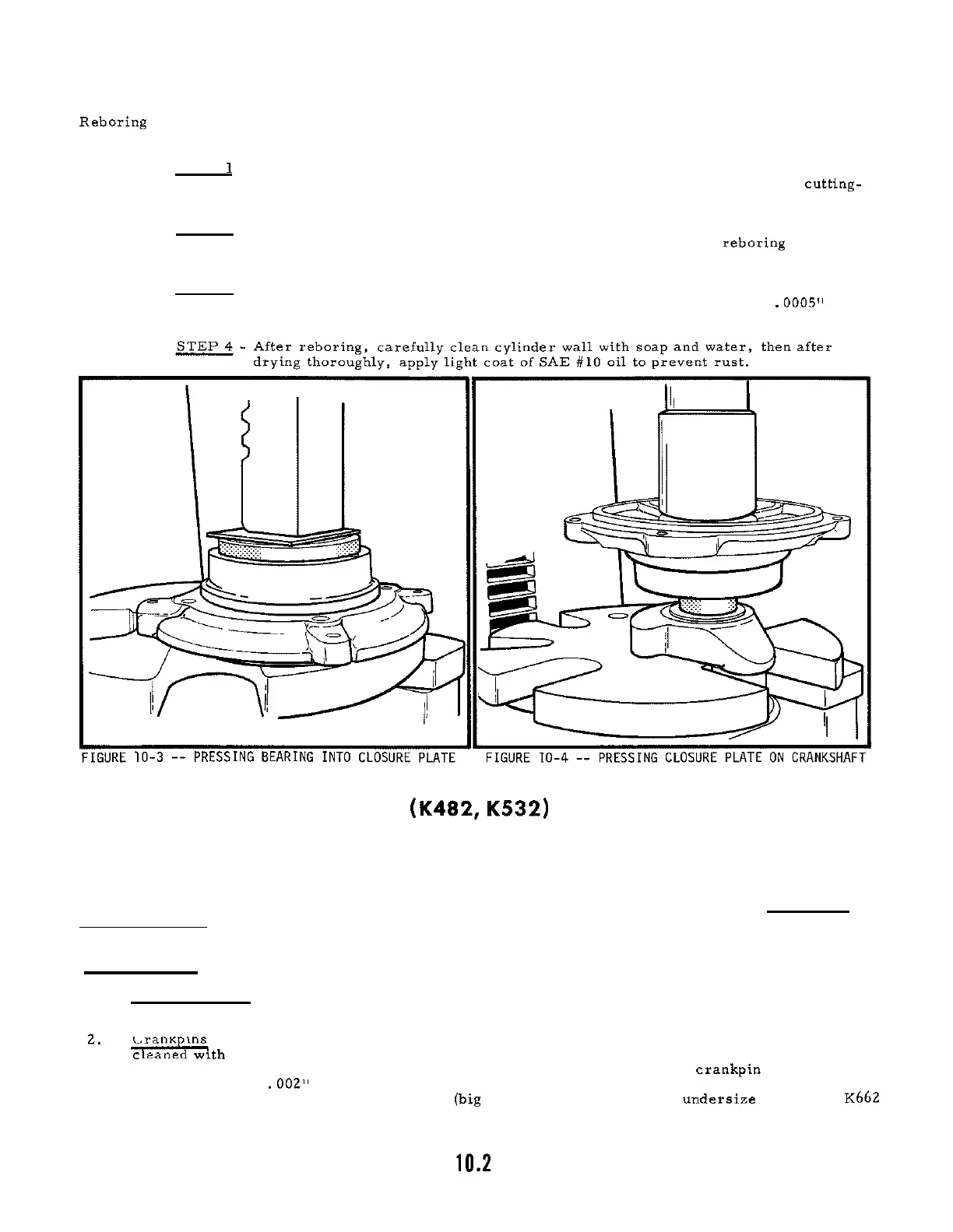

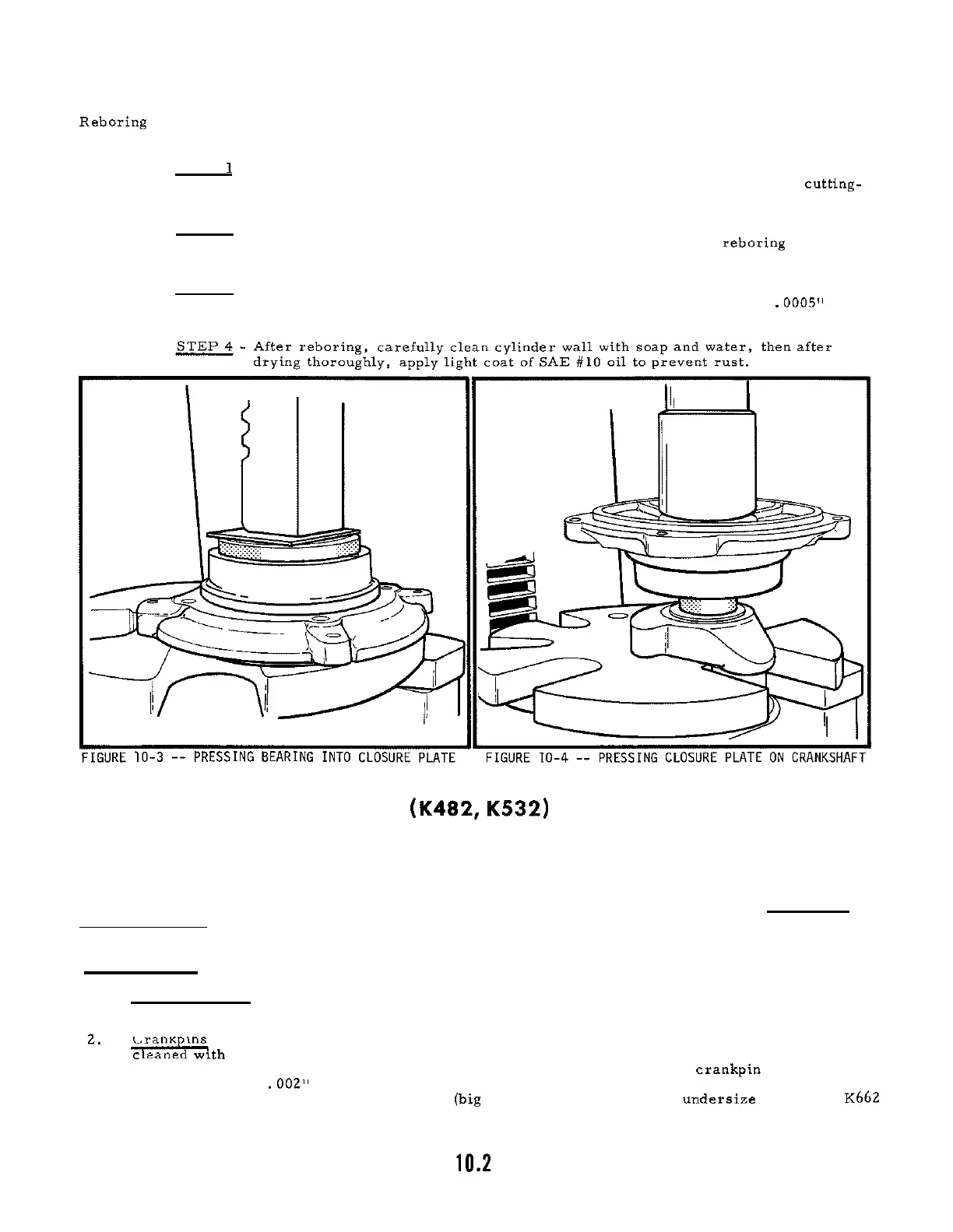

CRANKSHAFT

-

CLOSURE PLATE (K482, K532)

Some engines use a ball bearing which

is

locked in place in the closure plate and on crankshaft.

On these engines, it is not necessary to separate the crankshaft from the closure plate if the bearing

turns easily and noiselessly on the shaft.

Replacement of the bearing is not usually necessary.

To

recondition or replace bearing, remove inner retaining ring then press crankshaft out of closure plate.

The bearing will remain on the shaft and can be pressed off after two remaining snap rings are removed,

if this

is

necessary.

To clean ball bearings,

swish in cleaning solvent, allow to drip dry (do not spin

dry with air hose), then re

-

oil with Light weight engine oil.

CRANKSHAFT

1.

Keyways

-

Gears

-

If keyways for flywheel are badly worn or chipped, replacement of the crank

-

shaft may be necessary.

Crank ins

-

Inspect crankpins for score marks or metallic pickup.

Slight score marks can be

2.

+

c

eaned w~th crocus cloth soaked in oil.

If wear limits, as stated in Clearance Section are

exceeded, it will be necessary to either replace crankshaft or regrind the

crankpin undersize.

On K662 models,

.002" undersize bearings are available for crankpins worn ,002

"

undersize.

The appropriate undersize connecting rod

(big end) on K482 and K532 or undersize bearing on K662

must then be used to achieve proper running clearance.

Loading...

Loading...