KOHLER #A

-

271923 (MODEL PC2-10) GAS CARBURETOR

The model

PCZ-10 can be classified a diaphragm type carburetor although it also uses a venturi.

The diaphragm arrangement provides final regulation of the fuel which is received from the primary

regulator (or vaporizer

-

regulator) at a pressure of about

8

psi. This pressure setting must not exceed

12

psi.

The PC2 serves two functions

--

as a carburetor and as the secondary regulator.

Operation:

Fuel is supplied to the carburetor at above atmospheric pressure

--

as long as inlet pres

-

sure does not exceed 20 psi, the regulator segment will block off fuel and prevent leakage into the

engine when it is not operating.

Briefly,

when the engine is in operation, flow of air thru the carbure

-

tor causes pressure differences which act upon diaphragms which, in turn, activate a fuel lever to

admit fuel according to engine demand. When the engine is at low idle speeds, the fuel is directed

into the engine thru separate idle discharge jets which permit operation even when flow of air through

the venturi would be too low to draw sufficient fuel to sustain operation. The carburetor also features

a back suction type of

"

economizer

"

which meters an economy mixture of fuel during part throttle and

part load operation. At full throttle and full load operation, the position of the throttle plate is such

that maximum fuel is metered to the engine. The maximum amount

of fuel allowed is determined by

setting of the main fuel (load) adjustment.

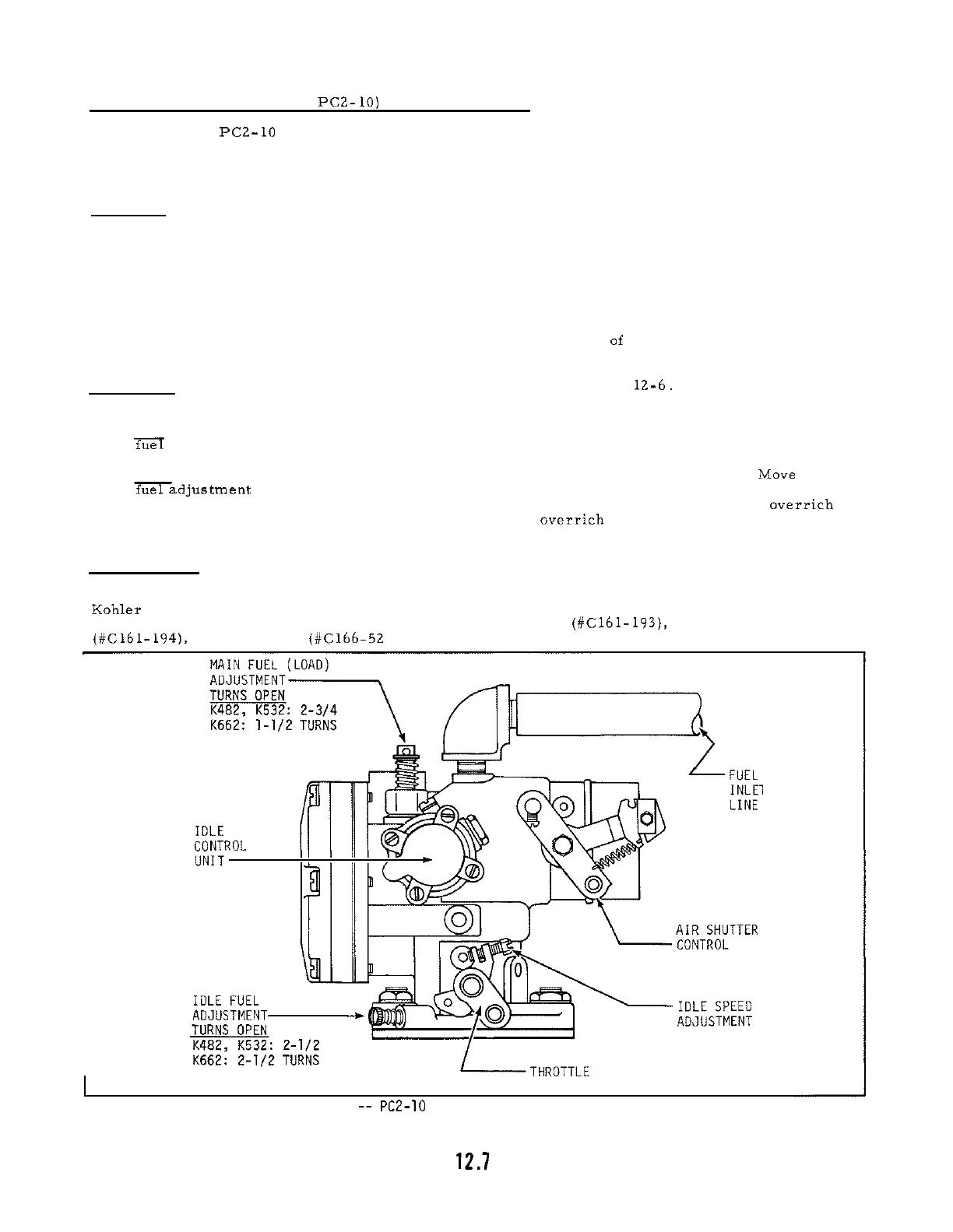

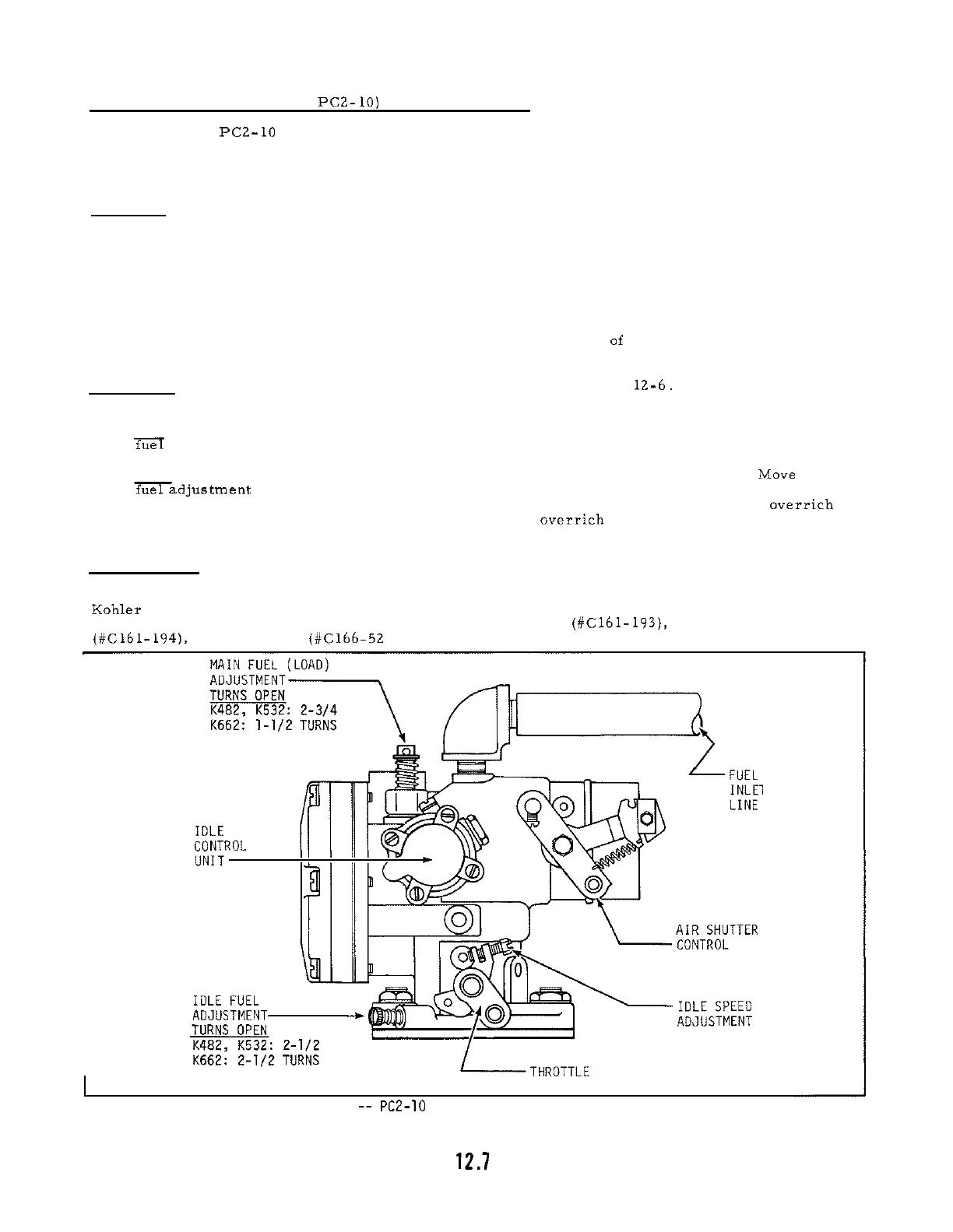

Adjustment: For preliminary adjustment of carburetor refer to Figure

12-6. Turn screws in lightly

against seats

--

before opening

--

do not force closed. Final adjustments are made as follows:

Idle:

Start engine, move throttle to idle position,

adjust idle speed to proper range. Move idle

adjusting screw in and out until smoothest idle is attained.

Load:

Allow engine to warm up, then open throttle and place under normal load.

Move main

-adjustment in until engine starts to slow down from lean mixture then turn adjustment in the

opposite direction until engine speed increases then starts to slow down again from

overrich

mixture. Move adjustment halfway between lean and overrich settings for best mixture under

normal load.

Reconditioning: The PC2 does not require service at regular intervals.

If carburetor troubles occur

that cannot be remedied by readjustment, the carburetor should be completely disassembled and recon

-

ditioned. Replace all diaphragms, gaskets, O

-

rings and dust seals when reconditioning. Use the

Kohler Repair Kit

(see

parts manual) for this carburetor when reconditioning. The following special

tools are required for satisfactory overhaul:

Main Jet Wrench

(#Cl6l-193), Fuel Valve Lever Gauge

(#C161-194), Aligning Studs (iiC166-52 set).

LEVER

FIGURE

12

-

6

--

PC2-10

GAS CARBURETOR

Loading...

Loading...