40

ACTUATOR MOTOR ELECTRICAL TESTS

The following tests are for troubleshooting the actuator motor and related circuits:

Use an AC voltmeter set for the proper range. Voltages in the tables are measure across the

motor reversing capacitor (between the colored motor lead wires.

If there is no ice in the evaporator(s) and the water plate(s) is (are) not fully closed (with the water

plate switch(es) pushed up and the “ARMS UP” LED on), the actuator motor(s) and pump(s)

should be running. If not, be sure there is power to the motor(s) and also that the motor(s) is(are)

not overheated and off due high temperature. Allow the motor to cool down before starting the

test procedure.

Always refer to the proper wiring diagram when troubleshooting.

Motor winding resistances at 75˚ F (24˚ C) out of the circuit are as follows:

REX 115 volt motors, white to black or yellow, approximately 95 ohms

REX 230 volt motors, white to red or yellow, approximately 400 ohms

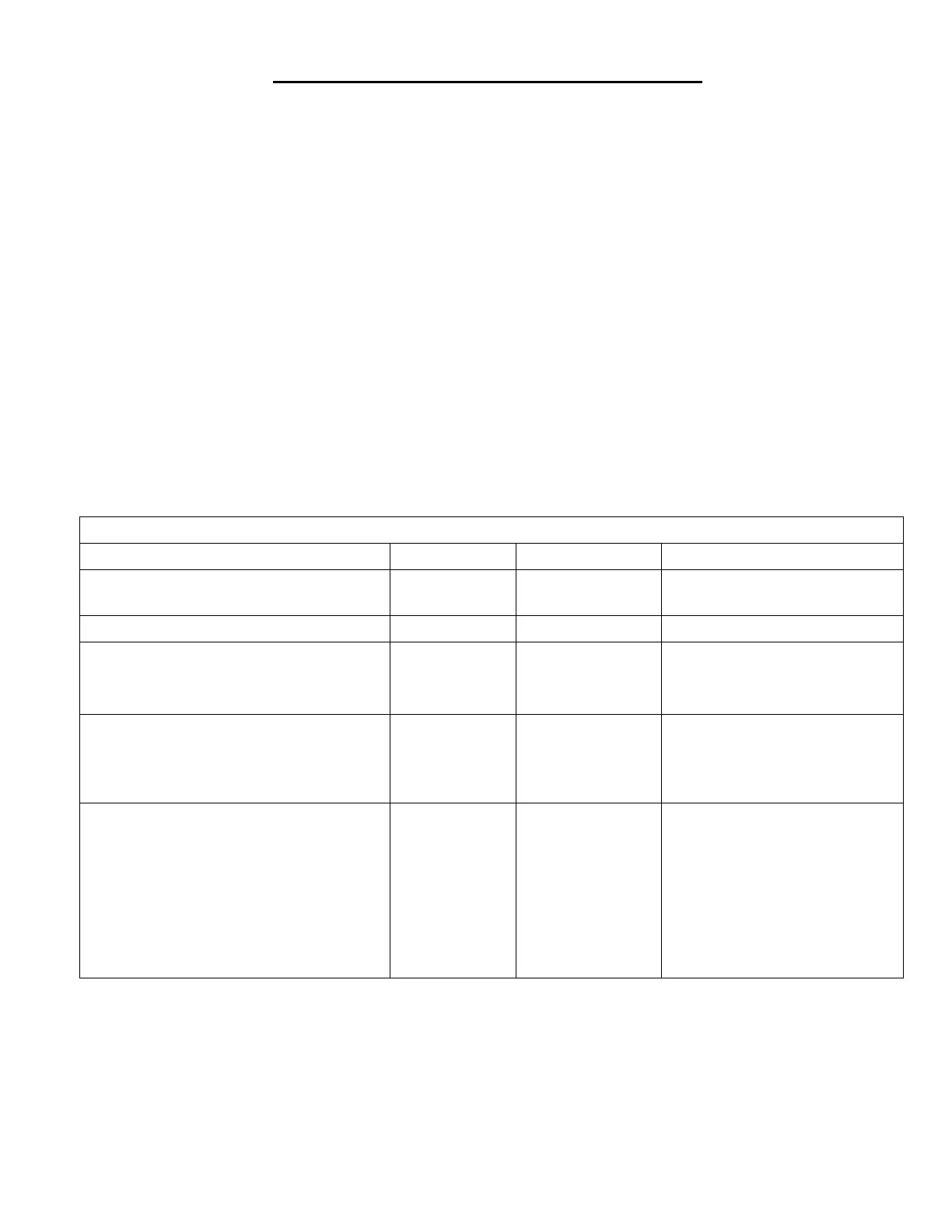

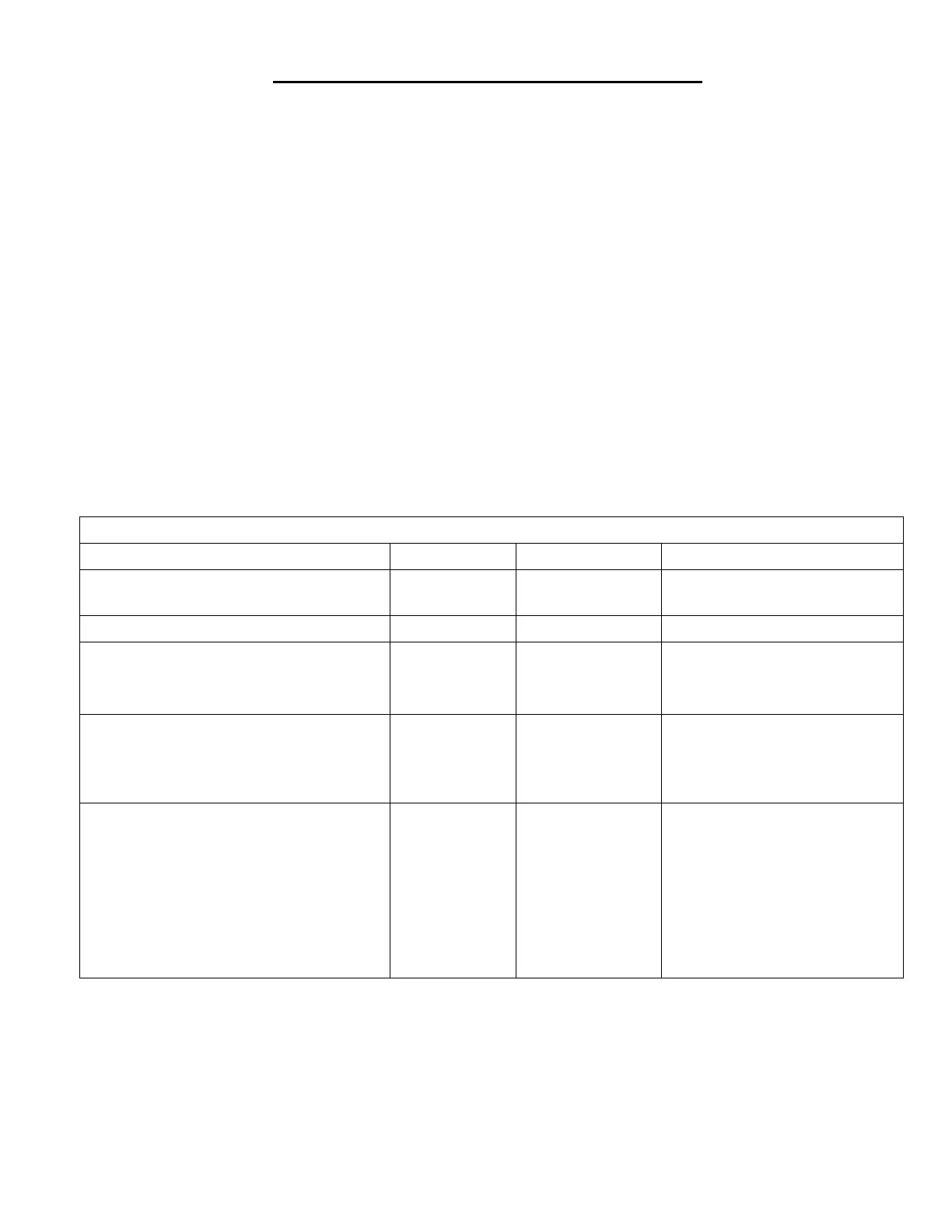

Voltages for Actuator Motor Electrical Tests

Actuator Motor Test Parameters

115 volt motors, reads 180-240 or

230 volt motors, reads 290-370

Tap gear case to align

bearings

Line voltage for any voltage motor

Line voltage for any voltage motor

in one actuator switch position and

0 volts in the other position

115 volt motors, reads 180-240 or

230 volt motors, reads 290-370

in one actuator switch position and

0 volts in the other position

0 volts in both actuator switch

positions. Be sure there is power to

the motor (line voltage) by leaving

one probe on either capacitor lead

and placing the other probe on the

white motor lead.

Disconnect the actuator

motor from the circuit and

test the winding resistance.

If approximately 500 ohms

from white to red or yellow,

replace the capacitor. If the

resistance is erratic, replace

the motor.

Loading...

Loading...