VI.2 Fault-finding

The table below should be regarded as a “First-aid” box. There may be a wide variety of

possible reasons for a fault, depending on the conditions in your system.

Multi-axis systems may conceal further causes of a fault.

Our applications department can give you further assistance with problems.

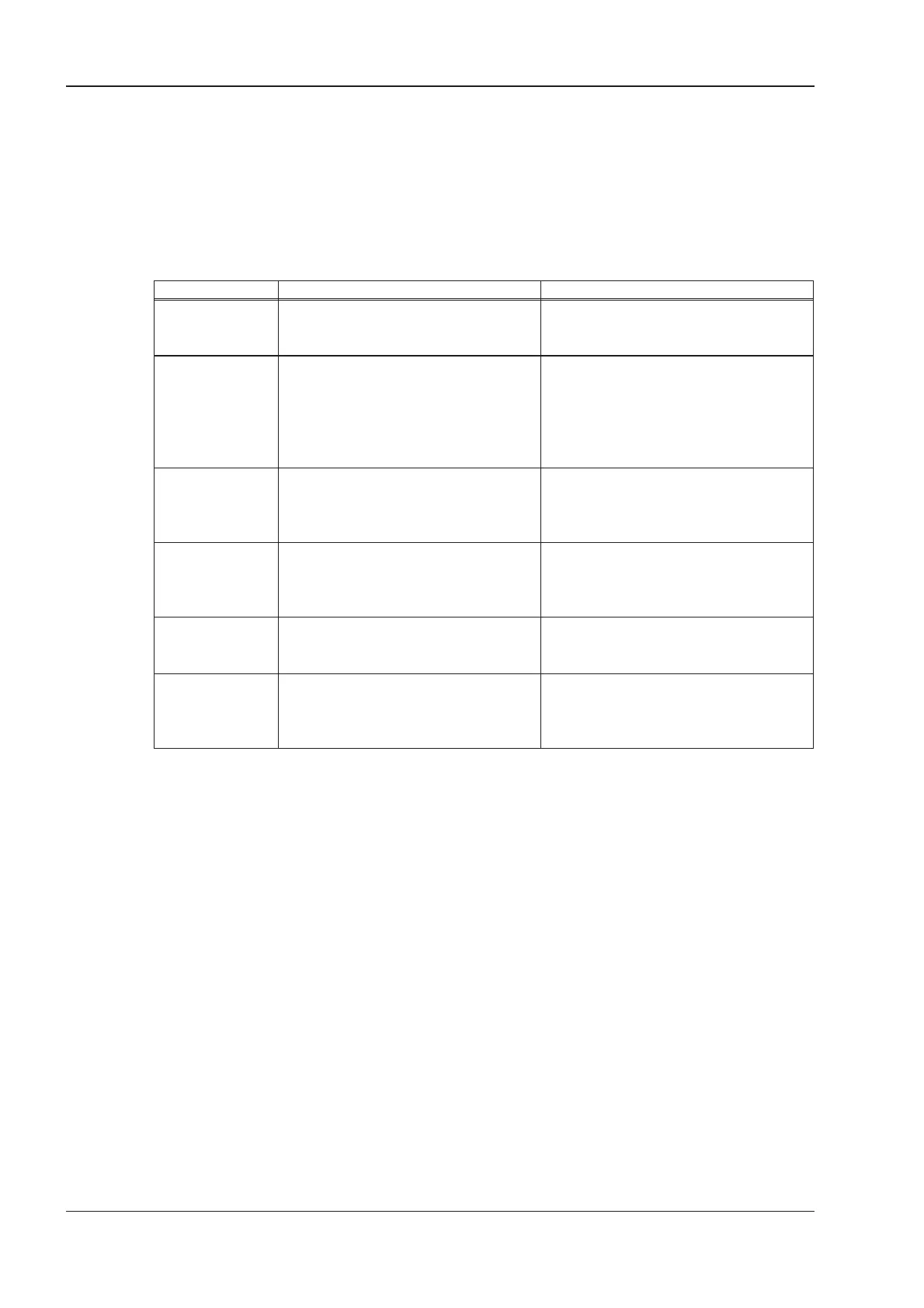

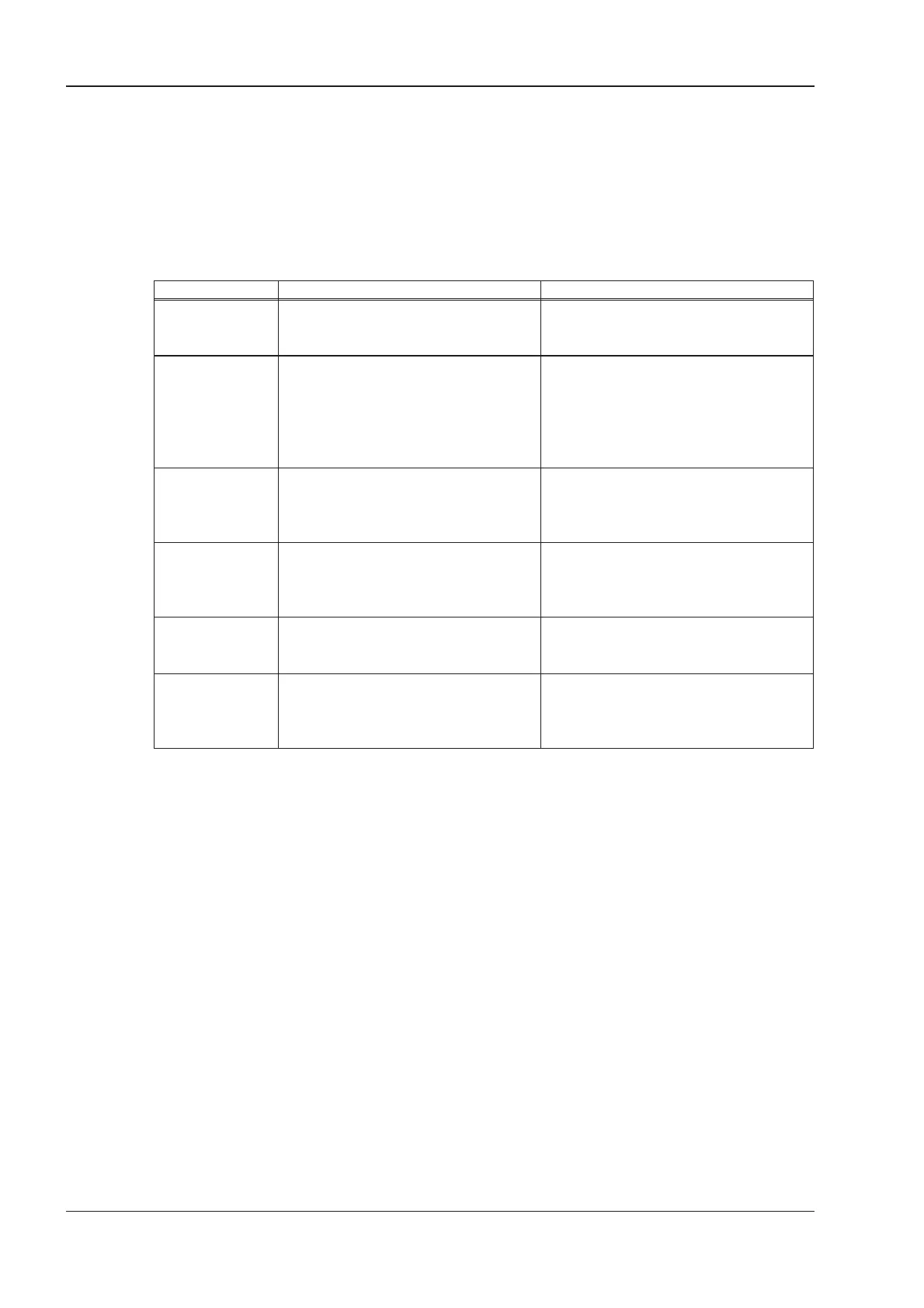

Fault possible causes ways to remove the cause of the fault

BTB-LED

not lit

— break in supply voltage

— fuse S1 or S2 blown

— 04S : check U1,V1,W1

-24V-: check 24V supply

— replace fuse

FAULT-LED

lights up

— motor faulty

— motor cable fault

— output stage too hot

— amplifier faulty

— replace motor

— replace motor cable

— ensure adequate ventilation,

check/clean fan, reduce

cabinet temperature

— return amplifier to manufacturer

motor does not

rotate, no torque

on the shaft

— Enable signal is missing

— DGND missing

— check wiring

— check wiring, LB2

motor does not

rotate, but

shaft has torque

— break in setpoint cable

— limit switch is activated

— brake not released

— drive is mechanically blocked

— check setpoint cable

— check PSTOP/NSTOP

— check brake control

— check mechanism

motor runs away

— motor connection faulty

— tacho cable faulty

— fault in motor tacho

— connect motor phases correctly

— check cable

— repair motor

motor oscillates

— AC-gain is too high

— break in tacho cable shielding

— AGND not wired up

— turn AC-gain potentiometer

anticlockwise

— replace tacho cable

— connect AGND to CNC-GND

new page

Page VI - 2 Appendix Chapter VI

Series 04S 12.99 Kollmorgen

Loading...

Loading...