MAINTENANCE

CRUSHER MAINTENANCE

251

• Repair any leaks immediately. Always relieve system pressure and lockout/tagout power before tight-

ening fittings or making repairs.

• Never attempt to adjust pressure relief valves higher than the specified settings. Serious personal injury

and/or equipment damage could result. Do not operate the hydraulic system with worn, damaged, or

leaking components. Always replace any defective components immediately.

• Never place hands on hydraulic cylinder rods while equipment is in operation. Do not step on the

hydraulic relief cylinder hoses.

• Refer to manufacturer’s instructions when recharging hydraulic accumulators or checking accumulator

pressure. Allow only trained hydraulic system technicians to depressurize, recharge or repair hydraulic

accumulators.

Crusher Daily Inspection Checklist

WARNING: Always lockout/tagout the equipment and depressurize the hydraulic

system prior to conducting these inspections.

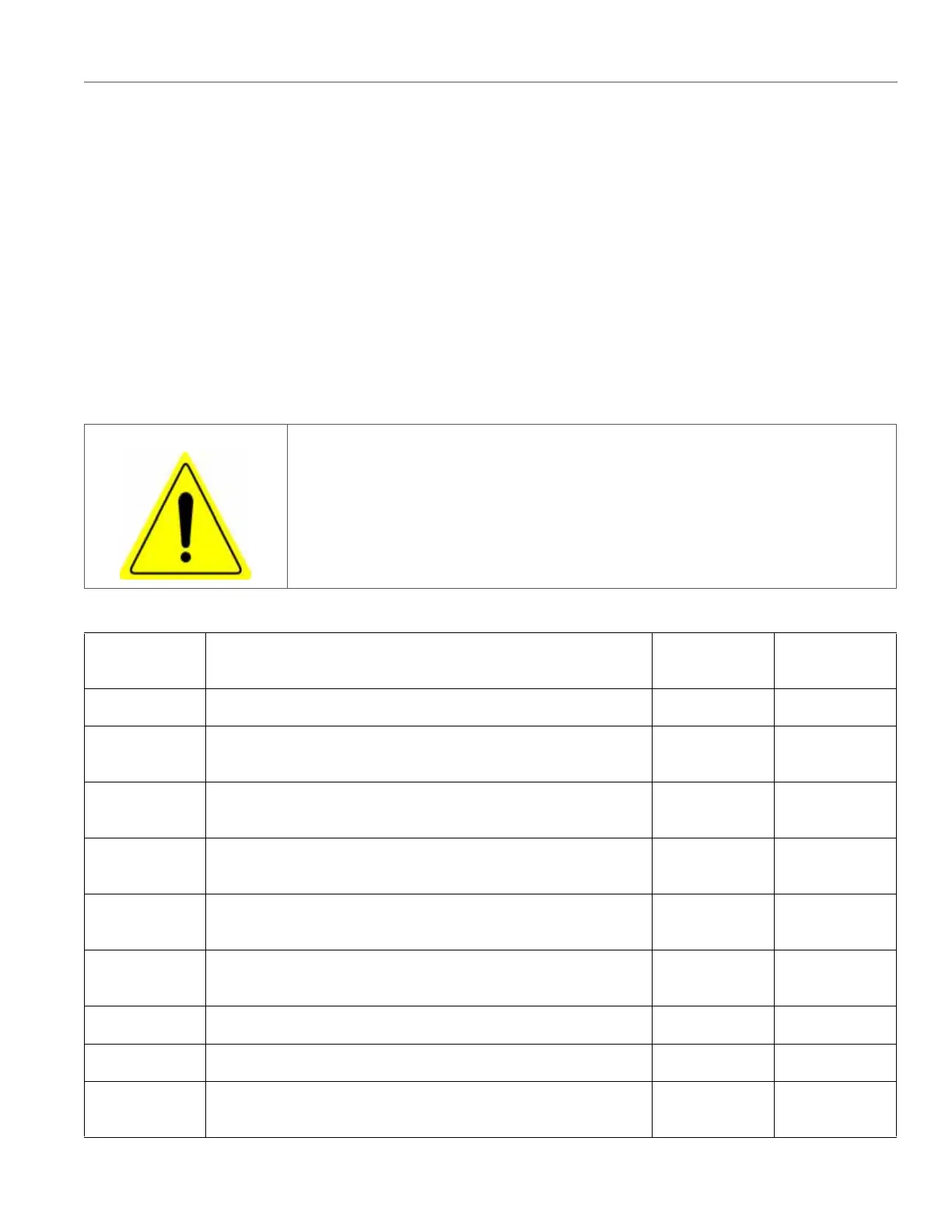

OPERATOR’S

INITIALS INSPECTION ITEM OKAY

SERVICE

REQUIRED

Check under the crusher and inside the baseframe.

Observe any changes in general appearance or signs of

progressive wear.

Remove any accumulated debris from struts and/or pinion

tunnel.

Look for physical damage to seal between bowl and bowl

support.

Check rotation stops for wear. Monitor and plan for

maintenance, if required.

Check lube and hydraulic oil levels prior to startup. Top off as

required.

Remove any accumulated dirt from drive sheaves.

Observe drive belt general condition. Service, if required.

Verify that there is no accumulation of rocks inside belt guard

that could damage belts and/or the pinion shaft.

Loading...

Loading...