Machine Operation

1. Prior to operating the machine make sure all safety guards are in place, and read and understand

all safety instructions in the machine manual.

2. Turn on the main power, handle on the starter box located on the right side of the machine; make

sure the emergency stop (“e-stop”) push buttons are pulled out.

3. Turn the control power on switch to the on position. The controller will come on to the startup

screen. Press the reset button on the front of the starter box located on the right side of the

machine. Press ENT/RET on the control key pad. The measuring bend roll will automatically

home itself.

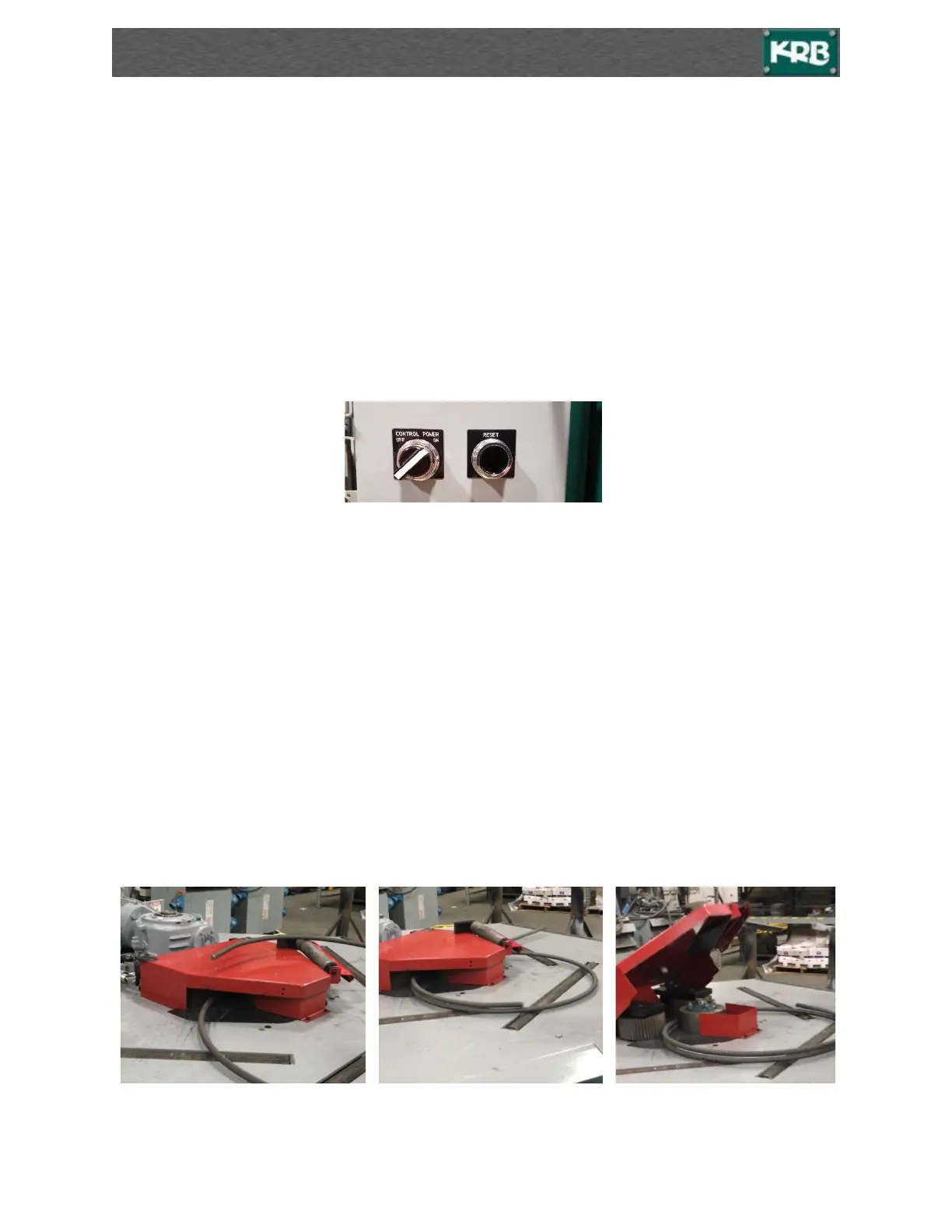

4. At this point do not start the drive rolls. Slide the bar you want to put a radius on between the drive

rolls and the measuring bend roll. Using the bend roll in/out switch. Run the measuring roll in until

it just touches the bar. This will be the starting point for determining the count needed to bend the

desired radius.

5. Remove the bar. Manually move the measuring bend roll in a few counts. Start the drive rolls and

run the bar through. Bar goes into the right and comes out of the left. Check the radius. If it’s not

correct keep repeating moving the bend roll and running the bar thru until you have the correct

radius.

6. When bending overlapping circles, bar may be manually guided above the guard, or back under

the guard. The guard is attached to a cylinder which allows it to open or close when pushing the

“Guard Open”/”Guard Close” buttons.

Note: If the guard is open, drive rolls will not turn.

Loading...

Loading...