Rev. Date: 12/27/17 Page 17

MODEL #1300/2300

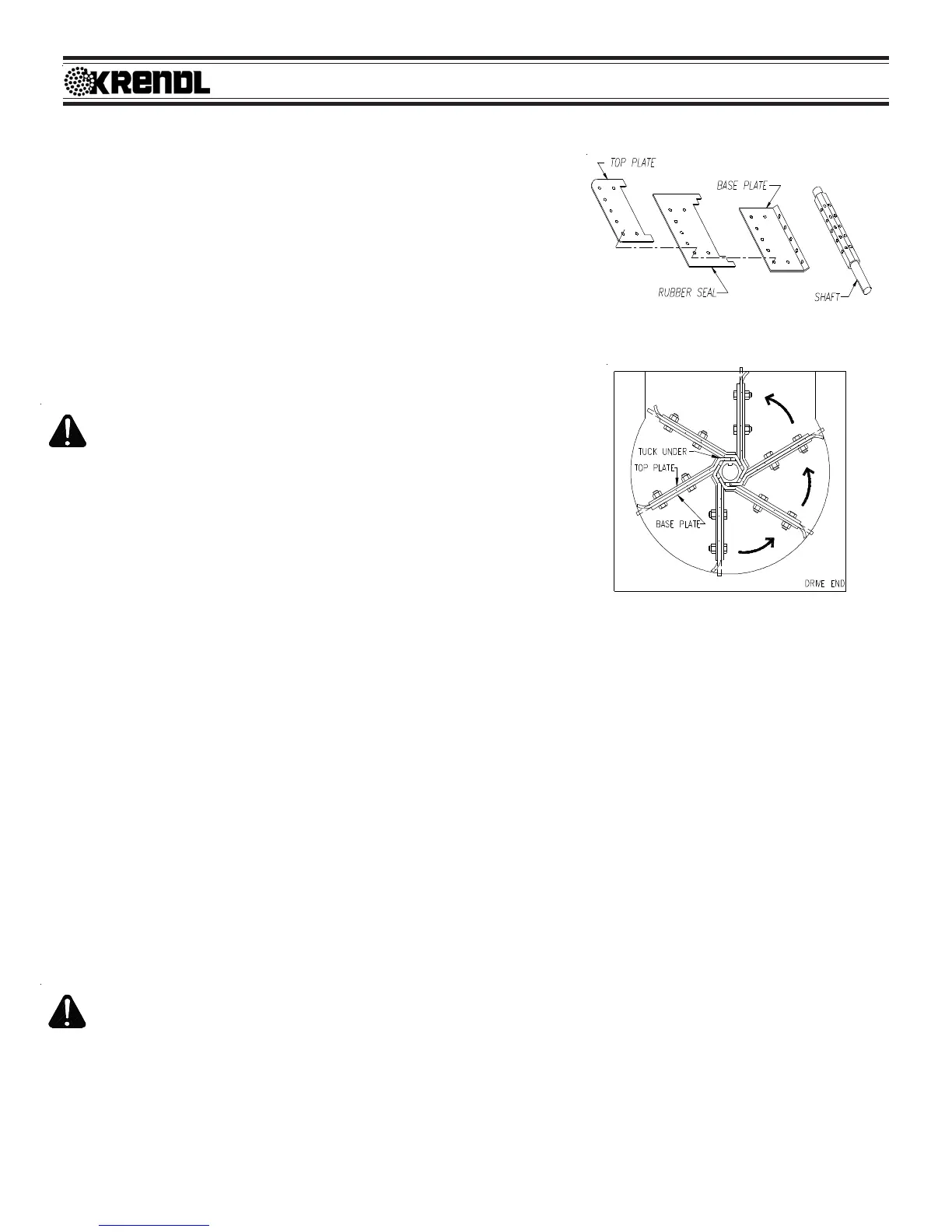

BASE PLATE REPLACEMENT:

1. Remove damaged baseplate assembly from shaft using ratchet

drive wrench with extension and 1/2" socket.

2. Check seal for wear and damage. (Installing seal and top plate

on the bench is quick and easy). Remove bolts from plate

assembly and replace with new seal. Make sure seal and top

plate are assembled on correct side of base plate before

assembling in airlock. Seal should press backward towards

top plate when

installed correctly into airlock chamber. (Illustra-

tion N)

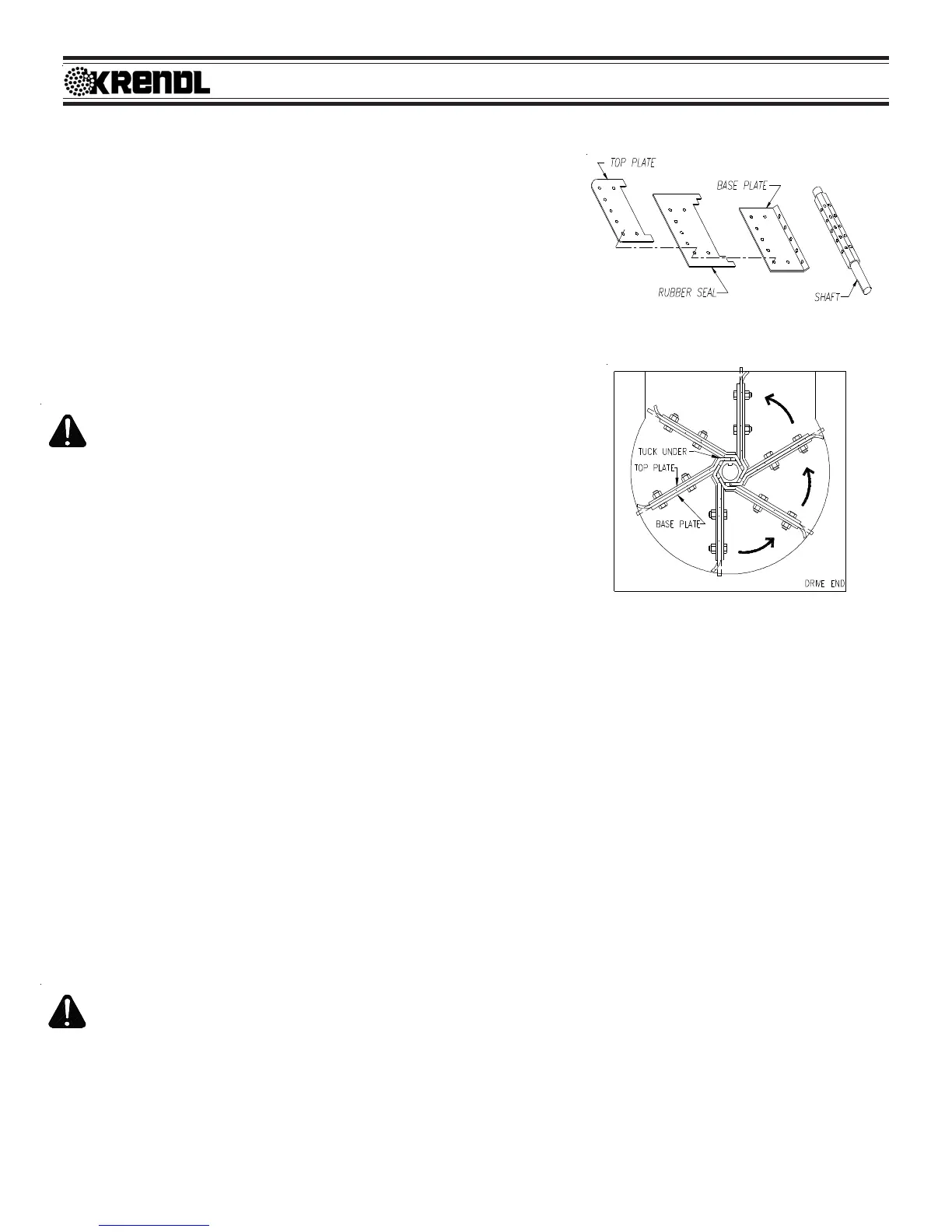

3. Install the rotor plate assembly into the airlock. The airlock runs

counterclockwise viewing it from the sprocket drive shaft.

(Illustration N) Align the base plate with holes on airlock shaft

using a tapered punch. Caution: Do not mount rotor plate

backwards. If installed improperly, damage to seals will result

and put undue stress on agitator motor. This causes overheat-

ing and poor production. Seal should be bent forwards to allow

for a counterclockwise rotation of rotor.

4. As rotor plate is installed, press bottom tab of seal under

adjacent seal with flat blade screwdriver. (See Illustration N)

Note: Entire rotor plate assembly may be removed and

replaced. This procedure maybe easier than replacing

just the seals.

General Maintenance (cont.)

(Illustration N)

CHAIN: (#50 Nickel Plated)

ADJUSTMENT: A smooth operating chain drive should have a slight sag on the idler side of the chain. New

chains should be installed under slight tension as they will elongate a small amount due to seating of pins and

bushings during the first few days of operation. Chain should be kept in good condition by proper lubrication (dry

film lubricant Dow 321) and occasional cleaning. Soaking chain in container of 10 weight oil will provide for

internal lubrication of pins and bushings. However, excess oil must be drained and wiped away as excessive

lubrication will cause insulation accumulation on chain. Worn out chain should be replaced. When chain is

replaced, worn sprockets should also be replaced, preventing further damage to new chain.

SPROCKETS:

CHECK SPROCKETS FOR WEAR. Misalignment and/or loose sprockets and improper chain tension causes

the premature wear of chain and sprockets. All sprockets, except speed reducer and idler sprockets, have been

secured with a medium grade Loctite (general purpose thread locker), to prevent gradual movement. The set

screws and key are also inserted with a medium grade Loctite. If sprocket is difficult to remove, it may be heated

with a propane torch to loosen.

Caution: Do not overheat sprocket or damage to bearing will result. A pulley or bearing puller can then be

used to remove the sprocket and key. Replace new sprocket on shaft with key and medium grade Loctite

applied to shaft. Align sprocket with corresponding sprocket, using a straightedge placed along face of

teeth and tighten set screw. Speed reducer sprocket does not require Loctite.

(Illustration M)

Loading...

Loading...