8 Servicing/Maintenance

45 of 60

WARNING

Failure to test overhauled valves

Hazard to persons and the environment!

▷ After reassembly and prior to commissioning/start-up, the valves must be

subjected to shell testing and leak testing to DINEN12266-1.

NOTE

Do not apply additional sealing agents to asbestos-free gaskets. In the case of

valves with anti-adhesive coatings, only use agents explicitly recommended by the

sealing element manufacturer.

8.2.2 (Re-)tightening the back-up gland packing

When delivered, the back-up gland packing is not fully tightened.

DANGER

Bellows failure

Leakage of hot and/or toxic fluids!

Risk of burns!

▷ Tighten the stuffing box screws (45-6) until no leakage can be seen.

Fig.9: Sectional drawing of

BOA-H

Table36: Stuffing box screws to DIN913

DN Thread Hexagon socket

15-100 M 10 SW 5

125-150 M 12 SW 6

200-350 M16 SW8

The valve must be replaced as quickly as possible to ensure proper functioning!

8.2.3 Removing electric, pneumatic or hydraulic actuators

DANGER

Removing/dismantling the actuators

Risk of injury!

▷ Observe the actuator's operating manual.

8.2.4 Tightening torques

8.2.4.1 Tightening torques for the bonnet/cover bolting

Use a torque wrench to tighten bolted/screwed connections 902/920 or 901 between

the bonnet/cover and the body.

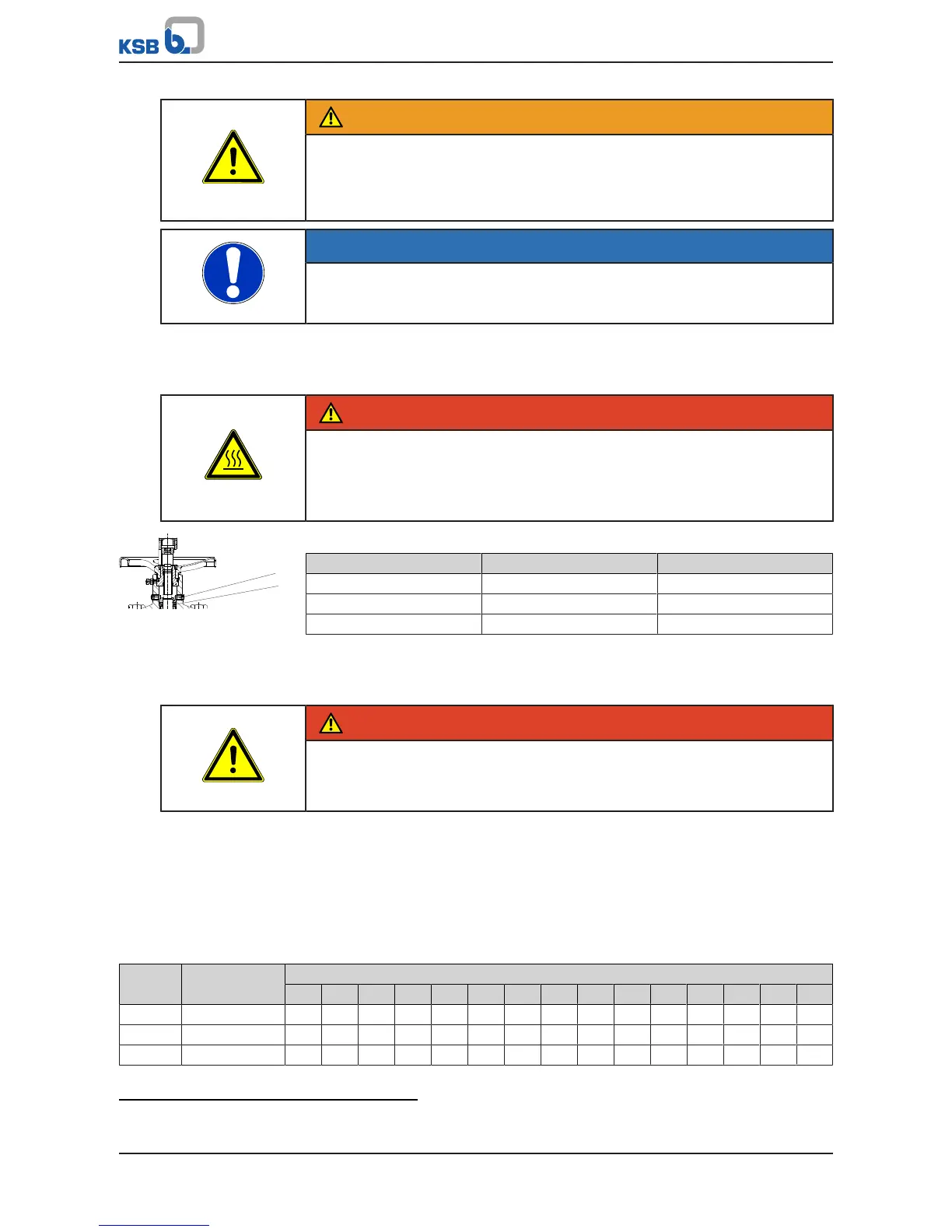

Table37: Bolt tightening torques, BOA-H [Nm]

PN Material DN

15 20 25 32 40 50 65 80 100 125 150 200 250 300 350

16 5.1301

33)

20 20 20 30 30 30 80 80 150 150 150 150 260 260 -

16 5.3103

34)

20 20 20 35 35 35 90 90 170 170 170 170 290 290 290

25 5.3103

34)

20 20 20 35 35 35 90 90 170 170 170 - - - -

33) EN-GJL-250 (JL1040)

34) EN-GJS-400-18-LT (JS1025)

Loading...

Loading...