▪ Mechanical seal (single-acting or in tandem arrangement)

▪ Gland packing with connection for barrier or flushing liquid in the cylindrical seal

chamber

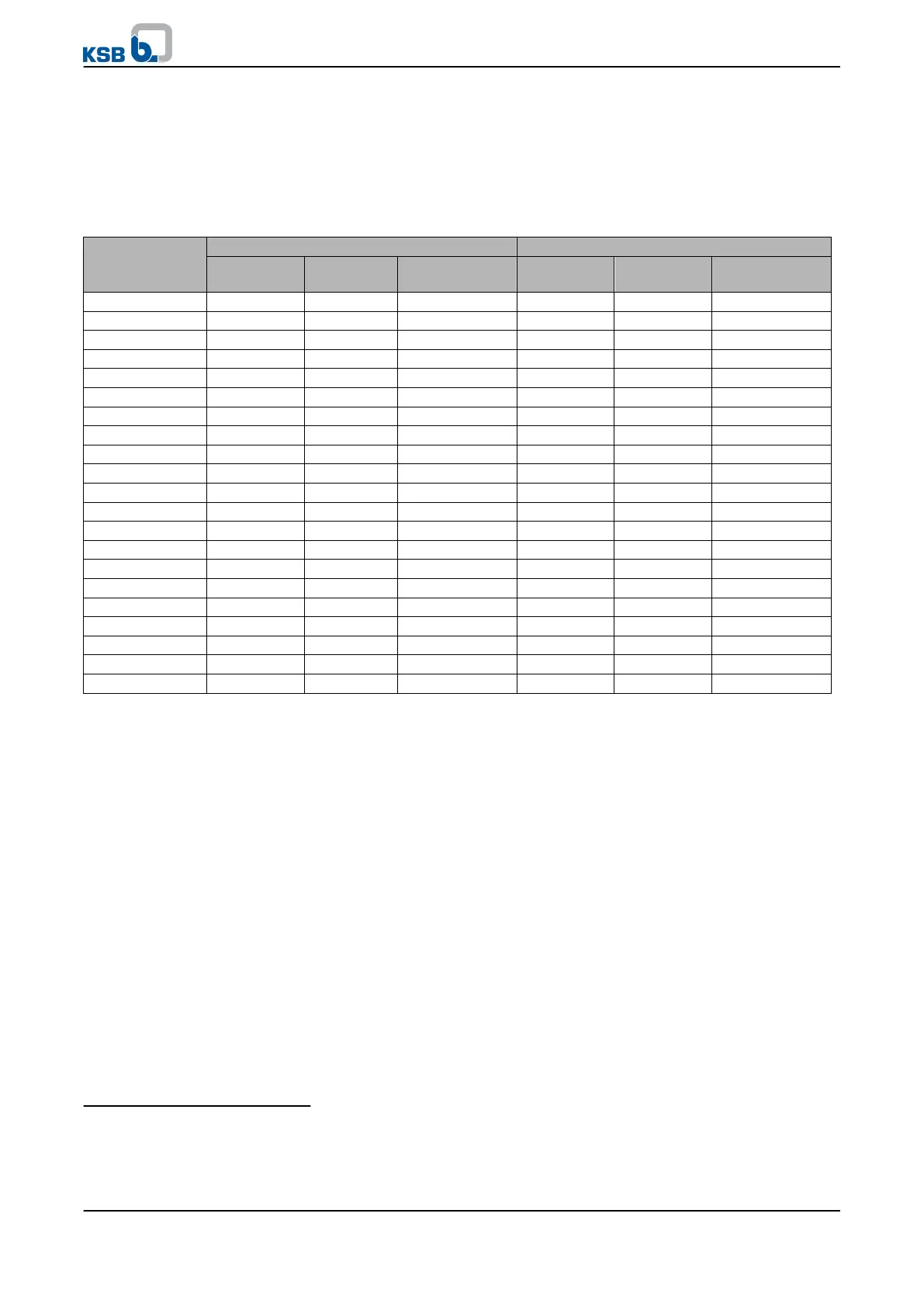

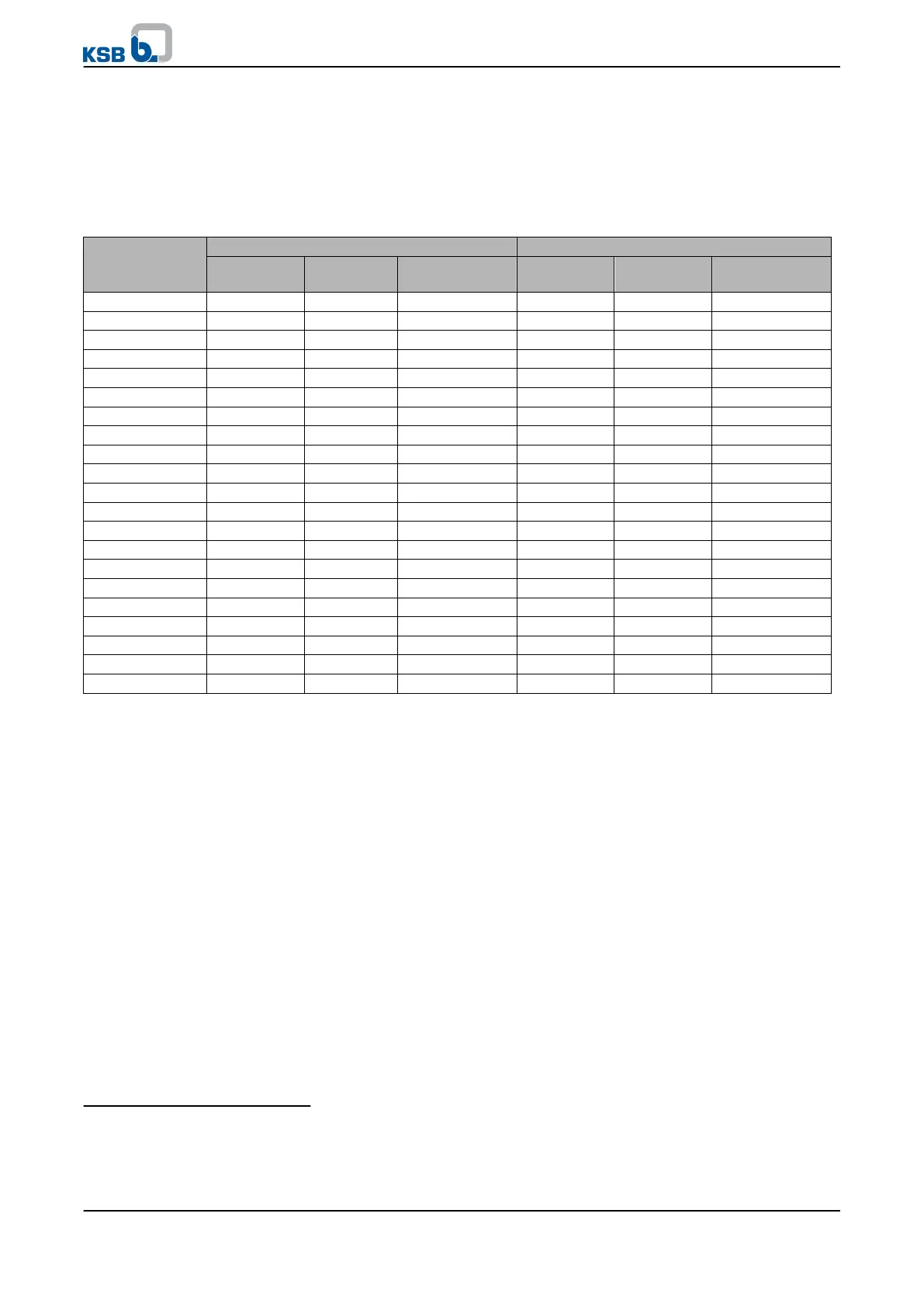

4.6 Noise characteristics

Table 9: Sound pressure level measured at surfaces L

pA

6) 7)

Rated power

input

PN [kW]

Pump set Pump

2900 rpm

[dB]

1450 rom

[dB]

960/760 rpm

[dB]

2900 rpm

[dB]

1450 rpm

[dB]

960/760 rpm

[dB]

1 63 57 55 54 52 51

2 65 59 53 55 53 52

3 67 61 59 57 55 54

4 69 62 61 58 57 55

6 70 64 63 60 58 57

8 71 65 64 61 59 58

11 73 67 66 63 61 60

15 74 68 67 64 62 61

19 75 69 68 65 63 62

22 75 69 68 66 64 63

30 76 71 69 67 65 64

37 77 71 70 68 66 65

45 77 72 71 69 67 66

55 78 73 71 70 68 67

75 - 74 72 - 69 68

90 - 74 73 - 70 69

110 - 75 73 - 71 70

132 - 75 74 - 72 71

160 - 76 74 - 73 72

200 - 76 75 - 75 74

250 - 80 79 - 76 75

4.7 Scope of supply

Depending on the model, the following items are included in the scope of supply:

▪ Pump

▪ Surface-cooled IEC three-phase current squirrel-cage motor

▪ Flexible coupling with or without spacer sleeve or belt drive

▪ Coupling guard to EN 294 or belt guard

▪ Baseplate (to ISO 3661), cast or welded, for pump and motor, in torsion-resistant

design

▪ As required

4.8 Dimensions and weights

For dimensions and weights please refer to the general arrangement drawing/outline

drawing of the pump (set).

Drive

Shaft coupling

Contact guard

Baseplate

Special accessories

6)

Spatial average to ISO 3744 and EN 12639. Applies to non-cavitating pump operation in the range Q/Qopt = 0.8 - 1.1. If

noise levels are to be guaranteed: Add +3dB for measurement and manufacturing tolerance.

7)

For 60 Hz operation: 1750 rpm, + 1dB; 1160 rpm, without allowance.

4 Description of the Pump (Set)

KWP

21 of 78

Loading...

Loading...