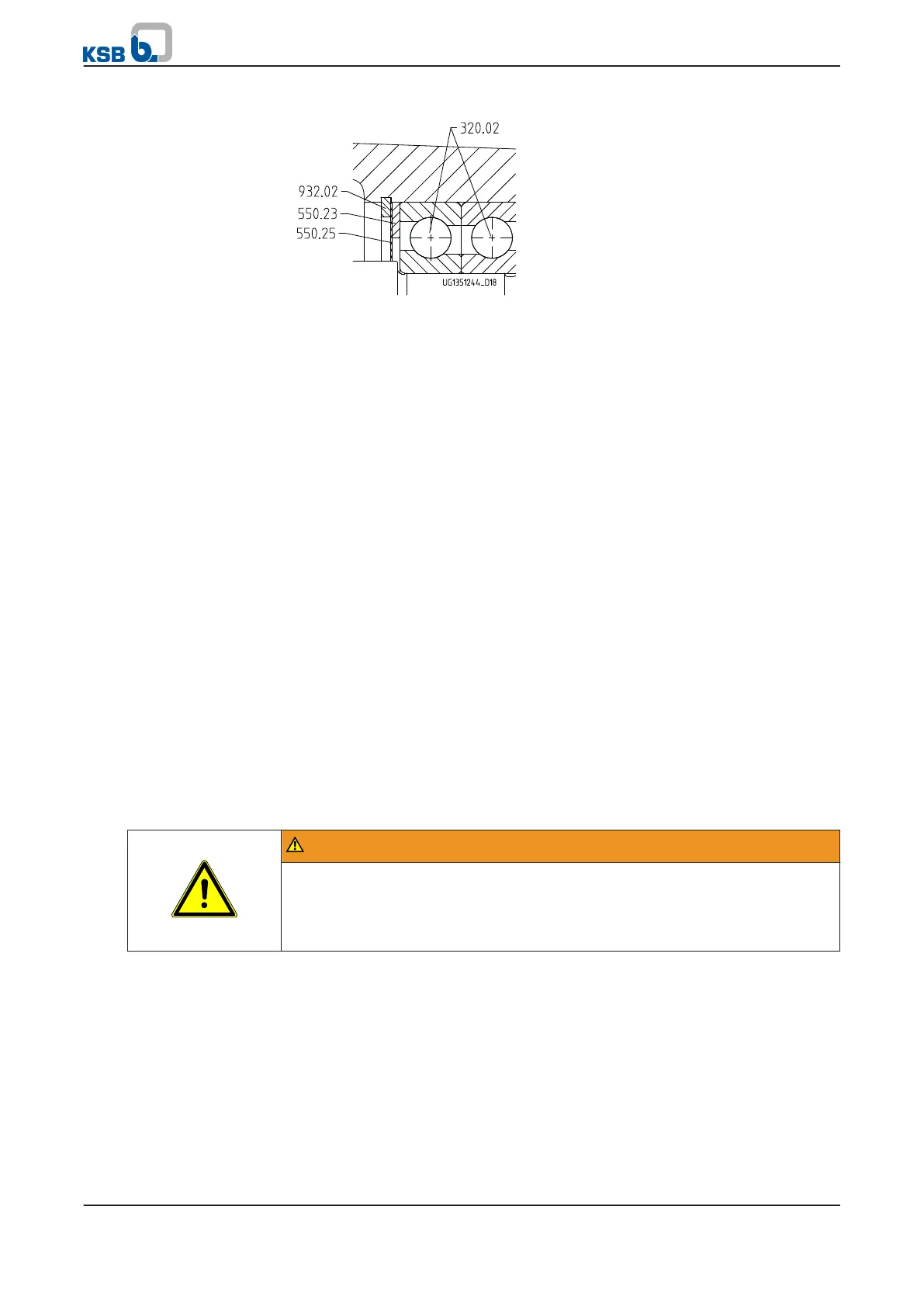

Fig. 18: Reassembling the medium-duty bearing assembly

13. On grease-lubricated models, insert disc 550.25.

14. Insert support disc 550.23 of angular contact ball bearing 320.02 into bearing

bracket 330.

15. Carefully insert pre-assembled shaft 210 with angular contact ball bearing

320.02 and the inner ring of cylindrical roller bearing 322.01 into bearing

bracket 330 from the drive end.

16. On grease-lubricated models, fill the bearing and bearing cover with grease.

Grease lubrication see (⇨ Section 7.2.3.2 Page 47)

17. Fit pump-end bearing cover 360.01 with joint ring 400.01; take care not to

damage lip seal 421.01.

18. Fit drive-end bearing cover 360.02 with joint ring 400.02; take care not to

damage lip seal 421.02.

19. Fit thrower 507.01 and 507.02, if applicable, and align flush with the shaft

shoulder.

20. Fit keys 940.02.

21. Slide the coupling hub onto the shaft end.

22. Secure the coupling hub with an adjusting screw.

7.5.2.2

Reassembling the economy bearing assembly

✓ The individual parts are kept in a clean and level assembly area.

✓ All dismantled parts have been cleaned and checked for wear.

✓ Any damaged or worn parts have been replaced by original spare parts.

✓ The sealing surfaces have been cleaned.

WARNING

Hot surfaces due to heating of components for assembly/dismantling

Risk of burns!

▷ Wear heat-resistant protective gloves.

▷ Remove flammable substances from the danger zone.

1. Oil-lubricated models: Heat up deep groove ball bearing 321.01/.02 in an oil

bath to approx. 80°C and slide it onto shaft 210 until it will not go any further.

Grease-lubricated models: Press deep groove ball bearing 321.01/.02 onto shaft

210 in cold condition until it will not go any further. Only apply force via the

inner ring of the deep groove ball bearings.

2. Carefully slide pre-assembled shaft 210 with deep groove ball bearing

321.01/.02 into bearing bracket 330.

3. Fit pump-end bearing cover 360.01 with joint ring 400.01; take care not to

damage lip seal 421.02.

4. Fit drive-end bearing cover 360.02 with joint ring 400.02; take care not to

damage lip seal 421.02.

7 Servicing/Maintenance

54 of 74

MegaCPK

Loading...

Loading...