RDLO

Page 18 of 24

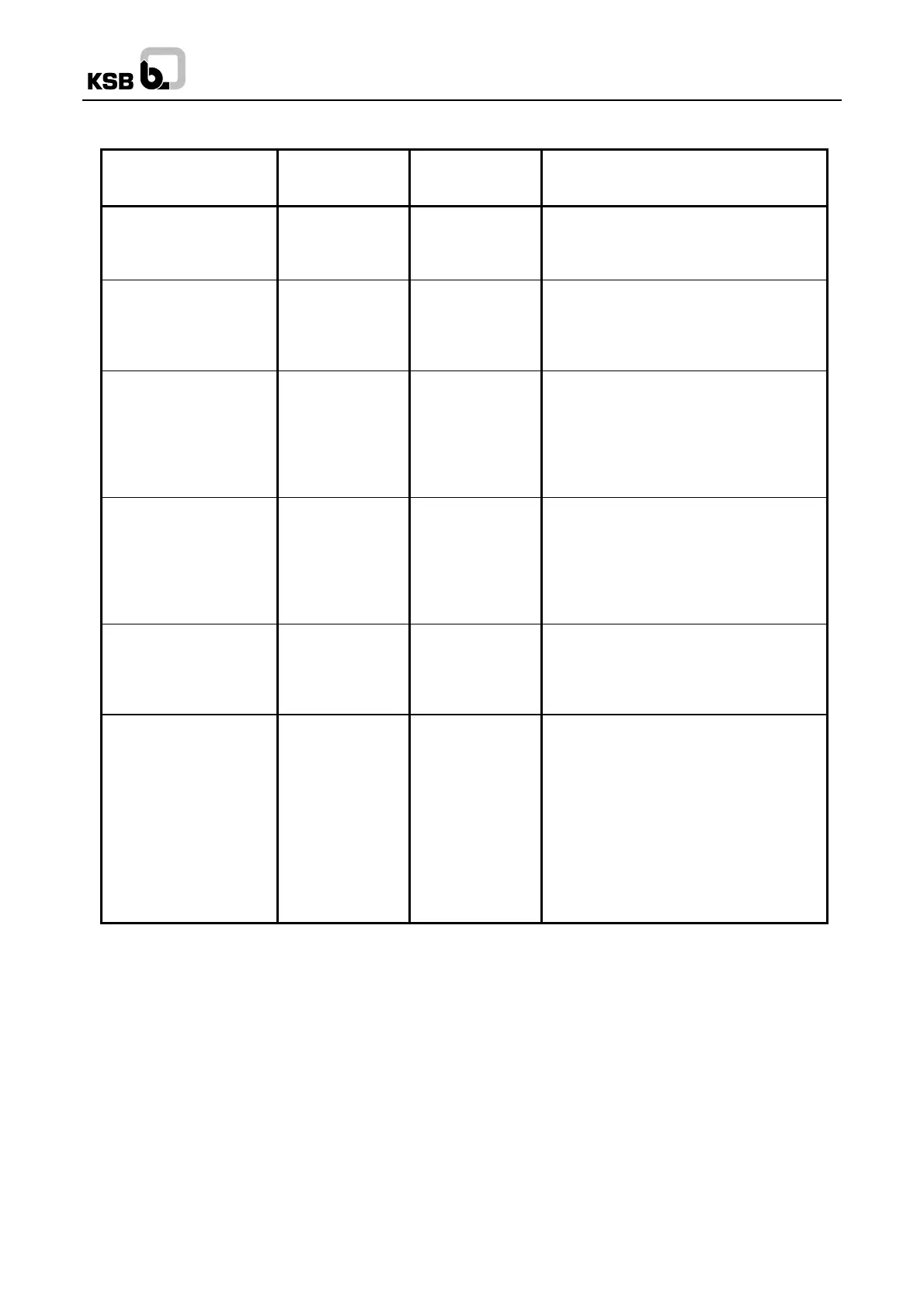

7.6 Routine Servicing and Inspection Intervals

Interval Number of

personnel

required

Time

(hours)

Servicing work

Daily 1 1/10

- Check mechanical seal for leakage

or leakage rate of gland packing

Weekly 1 1/4

- Check pump operation (suction

pressure, discharge head, bearing

temperature, noises and vibrations)

Monthly

1

1

1/4

1/4

- Check torsional clearance of the

coupling (see operating instructions

of the coupling in section 9.3)

- Switch to stand-by pump, if any, or

carry out a test run (for 5 minutes)

Every 4400 (radial ball

bearings)/

2 200 (radial roll

bearings

operating hours

11/4

- Re-lubricate grease-lubricated

rolling element bearings (re-

lubrication quantity, see technical

data sheets of pump in section 9.2)

Every 7 500

operating hours

11/4

- Oil-lubricated rolling element

bearings, see section 7.2.3.2

Every 4 years or if

discharge head

decreases

26

- General inspection and overhaul of

pump in accordance with the

operating instructions

Check and replace, if required:

- wear parts such as bearings,

casing wear rings, impeller wear

rings, shaft sleeves

- impeller and shaft

- seal elements

Loading...

Loading...