RDLO

Page 7 of 24

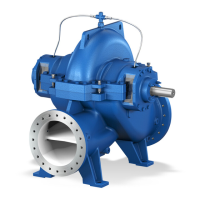

4 Description of the Product and

Accessories

4.1 Technical Specification

The KSB pump of the RDLO type series is a

horizontally installed, single-stage, axially split

volute casing pump with double-entry radial

impeller. Connecting flanges are manufactured on

option to ISO, DIN EN, or ASME.

RDLO is designed for use in waterworks, irrigation

and drainage pumping stations, power stations,

industrial water supply systems, shipbuilding as well

as general petrochemical applications.

4.2 Design Details

4.2.1 Pump Casing

Axially split volute casing with replaceable casing

wear rings.

Suction and discharge nozzles in the lower casing

half are at the same level (in-line design).

4.2.2 Impeller

The double-entry radial impeller is manufactured for

the individual operating data; including wear rings, if

requested.

In double-entry radial impellers the axial thrust is

largely balanced.

4.2.3 Pump Shaft

The shaft is fully sealed against the medium

pumped. Shaft protecting sleeves are fitted in the

seal area.

4.2.4 Shaft seal

The shaft is sealed on the driven and non-driven

ends by a gland packing or by a balanced

mechanical seal that is independent of the direction

of rotation.

The gland packings mounted on KSB pumps are

asbestos-free and suitable for drinking water

applications.

For a description of the mechanical seal, see

section 9.5.

4.2.5 Bearings and Lubrication

The pump is fitted on either side with grease-

lubricated or oil-lubricated (optional) rolling element

bearings. The locating bearing is situated on the

driven end.

4.3 Accessories

The accessories supplied with the pump are

specified in the relevant individual operating

instructions in chapter 9.

4.4 Dimensions and Weights

For dimensions and weights please refer to the

installation drawing in section 9.1.

5 Installation at Site

5.1 Safety Regulations

Electrical equipment operated in

hazardous locations of the zone 1 must comply

with the explosion protection regulations. This

is indicated on the motor rating plate.

If the equipment is installed in hazardous

locations, the applicable local explosion

protection regulations and the regulations of the

test certificate supplied with the equipment and

issued by the responsible approval authorities

must be observed and complied with.

The test certificate must be kept close to the

location of operation for easy access (e.g.

foreman's office).

5.2 Checks to Be Carried Out Prior to

Installation

All structural work required must have been

prepared in accordance with the dimensions

stated in the installation drawing.

The concrete foundations shall have sufficient

strength (min. BN 150) to ensure safe and

functional installation in accordance with DIN

1045 or equivalent standards.

Make sure that the concrete foundation has set

firmly before placing the unit on it. Its surface should

be truly horizontal and even.

5.3 Installing the Pump / Unit

Prior to installing the pump, check

the operating data. Check the

data on the name plate for compliance with the data

in the purchase order and the system data, e.g.

operating voltage, frequency, medium temperature,

etc.

The installation drawing in section 9.1 must be

observed.

Caution

Loading...

Loading...