RDLO

Page 13 of 24

r

r

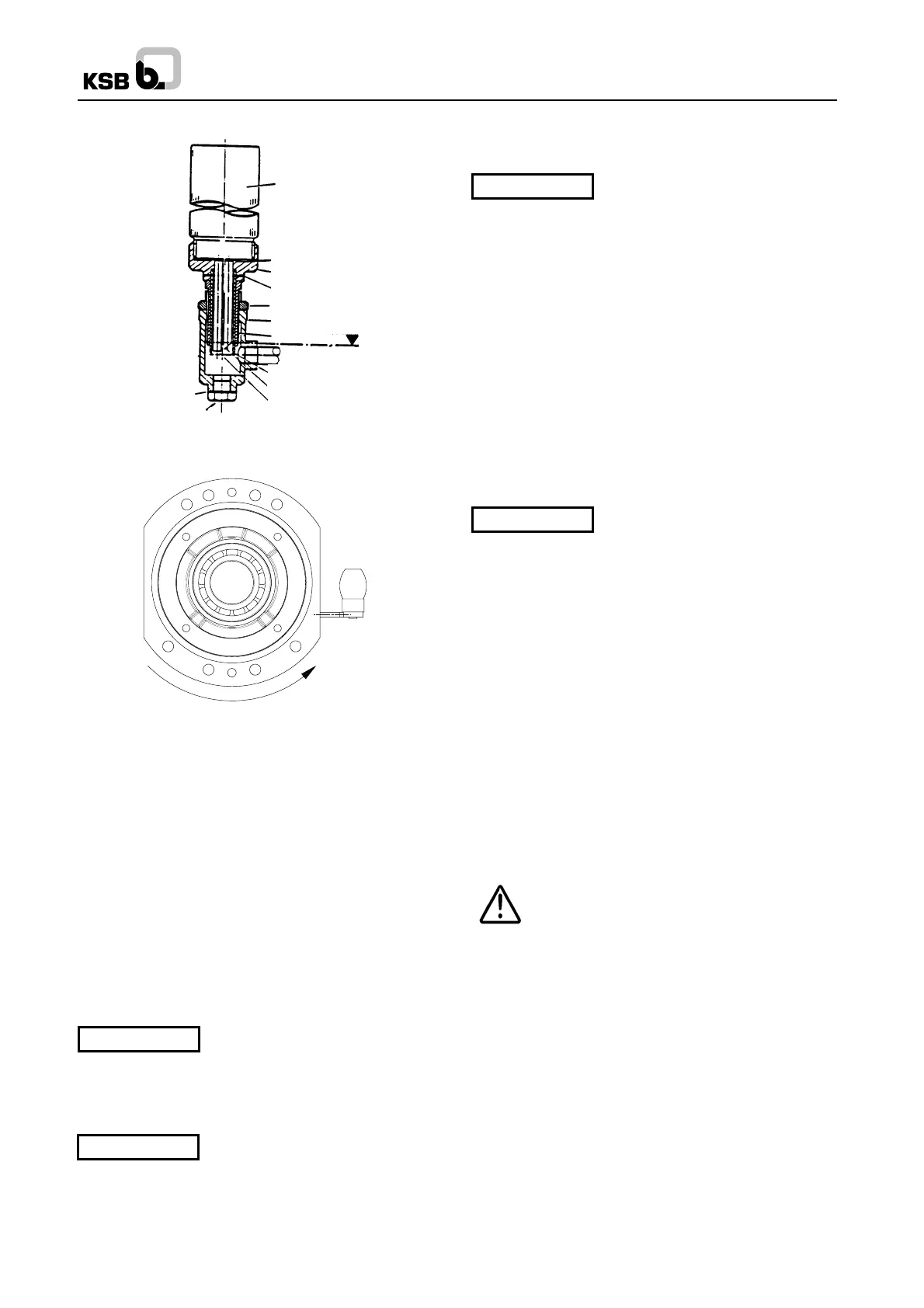

Gasket

Connection piece

Safety nut

Housing

Adjustment sleeve

Oil level

Split sleeve

Venting pipe

Oil pipe

Plug

Sight glass

Gasket

Air inlet openings

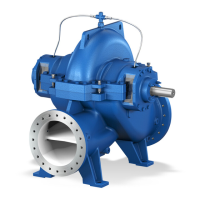

Constant-level oiler

Installation position of constant-level oiler

The constant-level oiler shall be mounted

depending on the direction of rotation as shown in

the figure above. The opposite hole shall be closed

with a plug.

Filling the constant-level oiler

Slacken the safety nut at the constant-level oiler,

draw out the oil reservoir of the constant-level oiler

and fill the reservoir of the constant-level oiler with

oil. Re-insert the oil reservoir of the constant-level

oiler and lock it.

As a general rule, oil should only

be topped up with the pump not

being in operation. Should it be unavoidable to top

up the oil of the constant-level oiler when the pump

is in operation, a temporary oil leakage might occur.

After a short time check whether

the oil level in the reservoir has

dropped. At least one third of the

reservoir must be filled with oil. If this oil level is

underrun, top up with oil.

The oil level must always be

below the vent opening arranged

at the top edge of the connection elbow! Make sure

the opening is always perfectly dry!

Oil Change Intervals

In order to ensure a long service life of the rolling

element bearings, the oil must be changed at the

following intervals:

1. Oil change after 300 operating hours

2. Oil change after 2000 operating hours

3. All subsequent oil changes after every 8000

operating hours, at least once a year.

The bearings must be cleaned thoroughly on every

oil change.

Always use clean oil!

Trouble

a) Oil reservoir empties,

oil level in the bearing housing rises.

Possible cause

Seal of oil reservoir is defective (air ingress).

b) Oil level in bearing housing falls,

no oil follows from the oil reservoir.

Possible cause

Vent opening at the connection elbow is clogged.

7.3 Dismantling

Before dismantling, secure the pump so as to

make sure it cannot be switched on accidentally.

The shut-off elements in the suction and discharge

lines must be closed. The pump must have cooled

down to ambient temperature, it must be drained

and its pressure must be released.

Dismantling and reassembly must always be

carried out in accordance with the relevant sectional

drawing.

7.3.1 Fundamental Instructions and

Recommendations

Caution

Caution

Caution

Caution

Loading...

Loading...