RDLO

Page 22 of 24

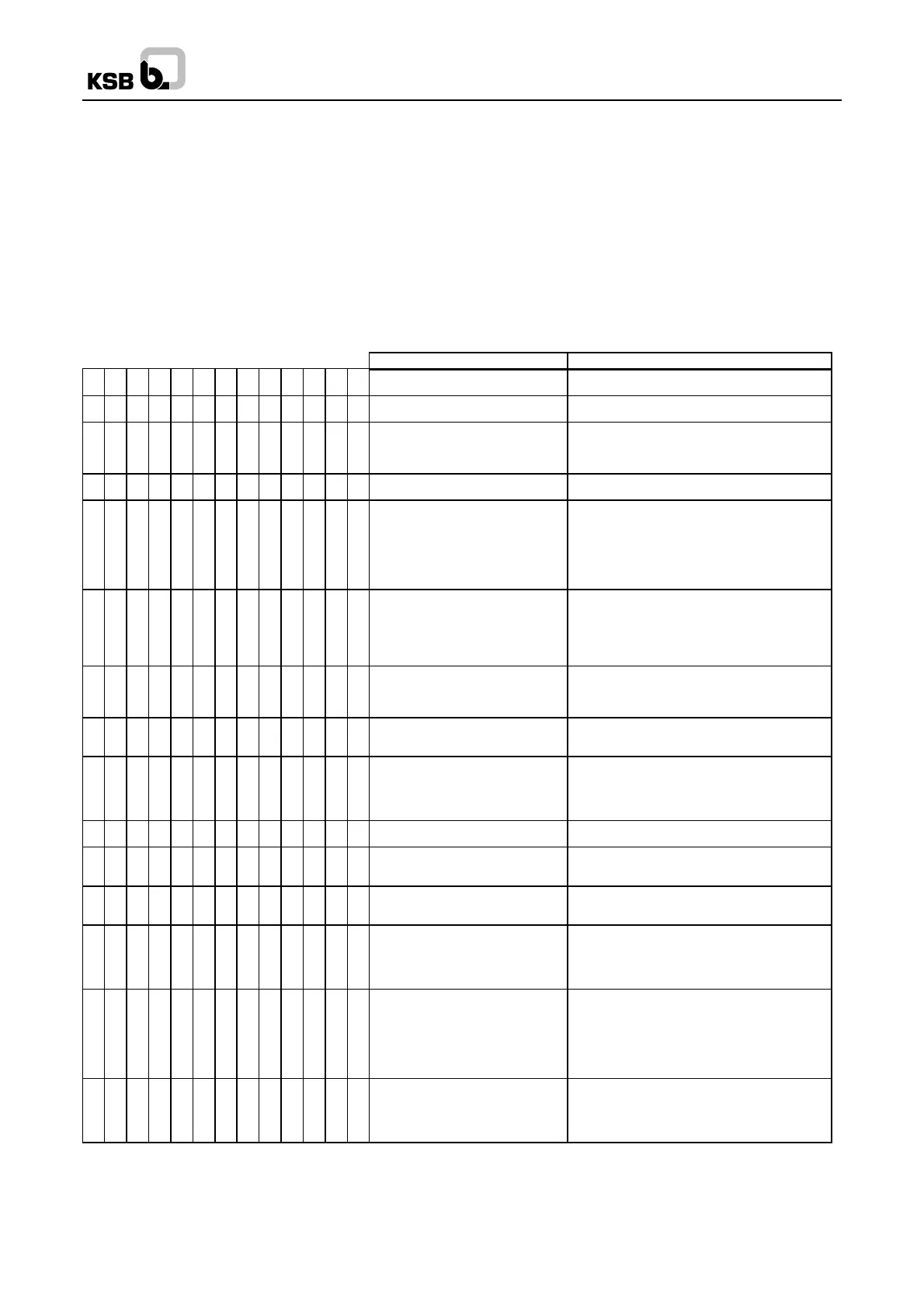

8.2 Causes of Faults and Their Remedies

Faults

Pump discharge pressure too low

| Pump discharge pressure too high

| | Excessive flow rate

| | | Insufficient flow rate

||||Power consumption is too high

|||||Pump does not deliver after starting

||||||Pump interrupts delivering

|||||||Pump runs rough (noise, vibrations)

||||||||Impermissible temperature increase at pump casing / shaft seal housing

|||||||||Bearing temperature too high

||||||||||Excessive leakage at the shaft seal

|||||||||||Drive is overloaded

||||||||||||Leakage at the pump

|||||||||||||

|||||||||||||

Cause Remedy

xxxxxx xx x

Duty point B does not lie at the

calculated intersections of Q and H

- Re-adjust the duty point

x

Pump or piping are not completely

vented or primed

- Vent

x x xxxx

Supply lines or impeller clogged - Clean the impeller

- Check plant for impurities

- Remove deposits in pump and/or piping

- Check any strainers installed / suction opening

x x x Formation of air pockets in the piping - Correct the suction conditions

- Alter the piping

x x xxx

Suction head is too high

(NPSH

available

is too low) / liquid

level is too low

- Check mode of operation

- Correct the suction conditions

- Increase the suction head

- Increase the back pressure by throttling

- Install pump at a lower level

- Alter the suction / intake piping, if the resistances

are too high

xxxx

Air intake at shaft seal - Clean the sealing liquid line, possibly supply

sealing liquid from an external source and/or

increase its pressure

- Check the liquid level in feed tank

- Replace the shaft seal

- Replace the shaft protecting sleeve

xxxx x

Wrong direction of rotation - Interchange two of the phases of the power

supply

- Check the electrical connections

- Check the impeller position; correct, if required

xx x

Speed is too low - Increase the speed

1)

- Check the switchgear

- Fit a larger impeller

1)

xxxx

Wear of internal pump parts - Check duty point / pump design

- Increase back pressure by throttling

- Check medium handled for contamination by

chemicals and the solids content

- Replace worn components

x x Back pressure is lower than specified

in the order

- Re-adjust the duty point

- Increase the back pressure by throttling

xx

Density or viscosity of medium

handled is higher than stated in the

order

- Reduce the speed

- In case of permanent overloading, turn down the

impeller

1

)

xx x x x

Speed is too high - Reduce the speed

- In case of permanent overloading, turn down the

impeller

1

)

x

Tie bolts / seals and gaskets - Check

- Tighten the tie bolts

- Replace the seals and gaskets

- Check pipe connections and secure fixing of the

pump; if required, improve the fixing of the piping

x

Shaft seal is worn - Check flushing / sealing liquid pressure

- Clean the sealing liquid line, possibly supply

sealing liquid from an external source and/or

increase its pressure

- Replace the shaft seal

- Replace worn components

- Replace the shaft protecting sleeve

xx xx

Unfavourable flow to suction nozzle of

pump

- Alter the piping

- If required, alter the suction / inlet pipe, if the

resistances are too high

- Check the piping layout for swirl or irregular flow

profile (e.g. downstream of an elbow)

1) Consult KSB

Loading...

Loading...