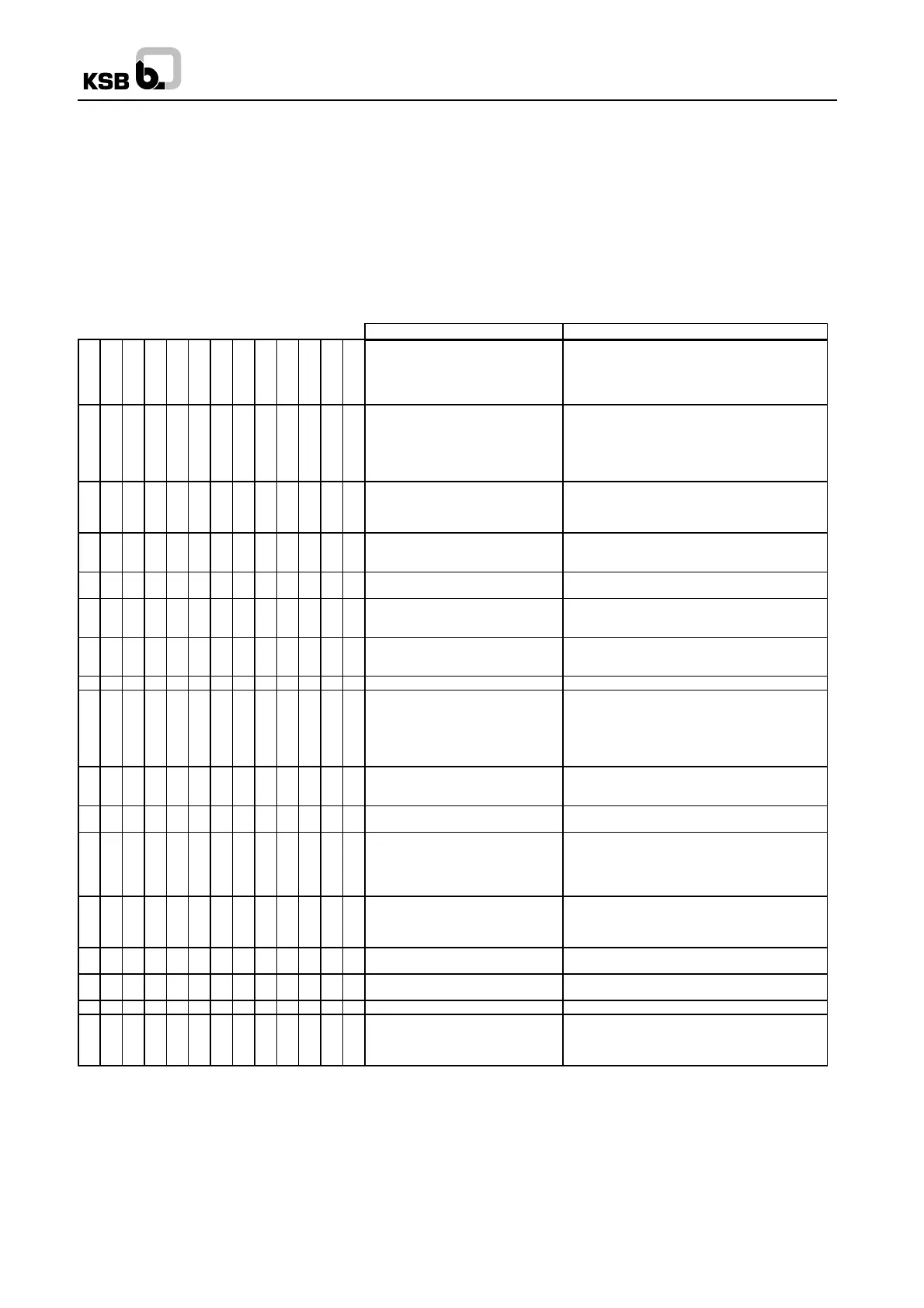

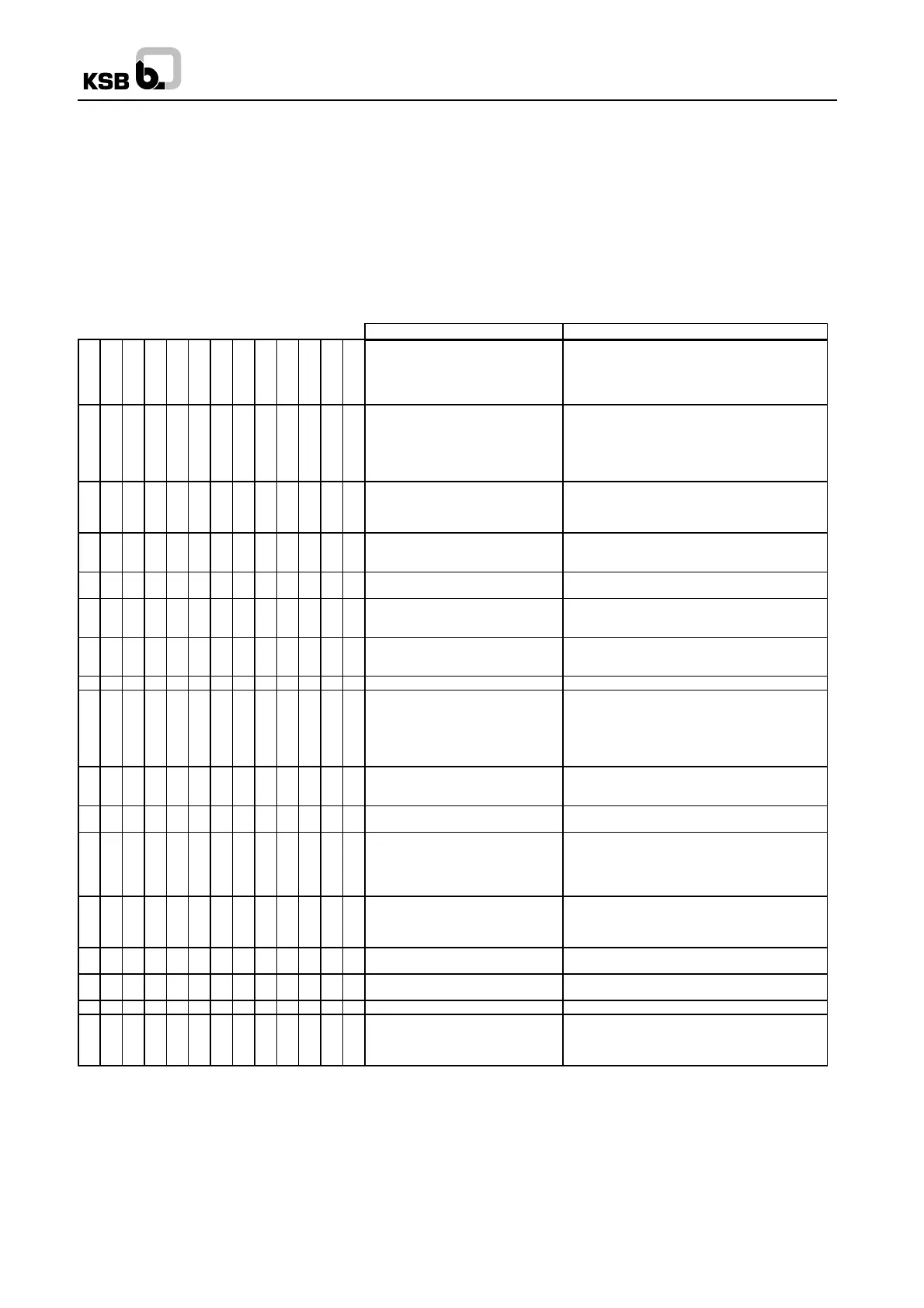

RDLO

Page 23 of 24

Faults

Pump discharge pressure too low

| Pump discharge pressure too high

| | Excessive flow rate

| | | Insufficient flow rate

||||Power consumption is too high

|||||Pump does not deliver

||||||Pump interrupts delivering

|||||||Pump runs rough (noise, vibrations)

||||||||Impermissible temperature increase at pump casing / shaft seal housing

|||||||||Bearing temperature too high

||||||||||Excessive leakage at the shaft seal

|||||||||||Drive is overloaded

||||||||||||Leakage at the pump

|||||||||||||

|||||||||||||

Cause Remedy

xx

Gland follower, seal cover (mech.

seal) have been tightened incorrectly;

wrong packing material

-Alter

- Replace

- Correct

- Replace the gland packing

- Replace worn components

xx

Lack of cooling liquid or dirty cooling

liquid chamber

- Check flushing / sealing liquid pressure

- Clean the sealing liquid line, possibly supply

sealing liquid from an external source and/or

increase its pressure

- Increase the cooling liquid flow rate

- Purify/clean the cooling liquid

xx

Pump is warped or sympathetic

vibrations in piping

- Re-align the pump / drive

- Check pipe connections and secure fixing of the

pump; if required, improve the fixing of the piping

- Take vibration-damping measures

x

Increased axial thrust - Check the duty point / pump design

- Check mode of operation

- Check suction flow

x

Insufficient or excessive quantity of

lubricant

- Clean the bearing

- Top up, reduce or change lubricant

xxx x

Motor is running on two phases only - Replace defective fuses

- Check the electrical cable connections

- Check the switchgear

xxx

Unbalance of rotor - Clean the rotor

- Check for run-out; re-align, if required

- Re-balance the rotor

x x x Defective bearings - Replace

xx

Insufficient flow rate - Re-adjust the duty point

- Fully open the shut-off element in the suction /

inlet pipe

- Fully open the shut-off element in the discharge

pipe

- Calculate or measure the hydraulic losses Hv

x x On star-delta starting, the motor does

not succeed in reaching the delta

stage

- Check the electrical cable connections

- Check the switchgear

x x x Impermissible air or gas content in

medium pumped

- Vent

- Check integrity of suction pipe; seal, if required

x x xxx

Air intake at pump inlet - Correct the suction conditions

- Reduce the flow velocity at the suction pipe inlet

- Increase the suction head

- Check integrity of suction pipe; seal, if required

- Replace defective pipes

x

Cavitation (rattling noise) - Correct the suction conditions

- Check mode of operation

- Increase the suction head

- Install pump at a lower level

x x Foundation not rigid enough - Check

-Alter

x x x x x Impermissible parallel operation - Re-adjust the duty point

- Alter the pump characteristic H

1)

x x Shaft run-out - Replace the shaft

xxxx

Impeller rubs against casing

components

- Check the rotor

- Check the impeller position

- Check whether pipe connections are free from

stresses or strains

1) Consult KSB

Loading...

Loading...