38 | MSD Legend Series Operation & Maintenance Manual

JAW BUILD UP & HARDSURFACING

Wear personal protection equipment (PPE) at all times.

This includes eye protection, hard had, steel toe shoes,

leather gloves and hearing protection that conforms to

standards ANSI Z87.1 (Eye and Face Protection), ANSI

Z89.1 (Head Protection), ANSI Z41.1 (Foot Protection)

and ANSI S12.6 (S3.19) (Hearing Protection).

Do not use stainless hardsurface rod or other improper

build up and hardsurfacing products. Using improper

products may result in premature wear or cracking of

the base metal.

Build Up Recommendations

Choose a build up material that meets the following classications.

Shielded Metal Arc Welding - Stick Electrodes

• E7018

• E8018-C3

Gas Metal Arc Welding - Solid Wire Electrodes

• ER70S-6

Gas Metal Arc Welding - Flux Cored Electrodes

• E71T-1

• E71T-1M

• E80T1-Ni1

• E80T1-Ni1M

Gas Metal Arc Welding - Metal Powder Cored Electrodes

• E70C-6M

• E80C-Ni1

Build Up Instructions

Wear personal protection equipment (PPE) at all times

maintain LaBounty products.

1. Disconnect InSite power cable before welding.

2. Throughly clean the area to be built up.

3. Preheat the area to 200° F (94° C) to remove moisture.

4. Heat the area to be built up to 400° - 450° F (204° - 233° C).

Note: Do not exceed 450° F (233° C)

5. Using AWS E7018 welding rod, make side by side

underlayment beads.

6. Relieve stress and remove slag after each pass by peening

vigorously with an air operated slag peener.

Note: Check the temperature often. Maintain 400° - 450° F

(204° - 233° C).

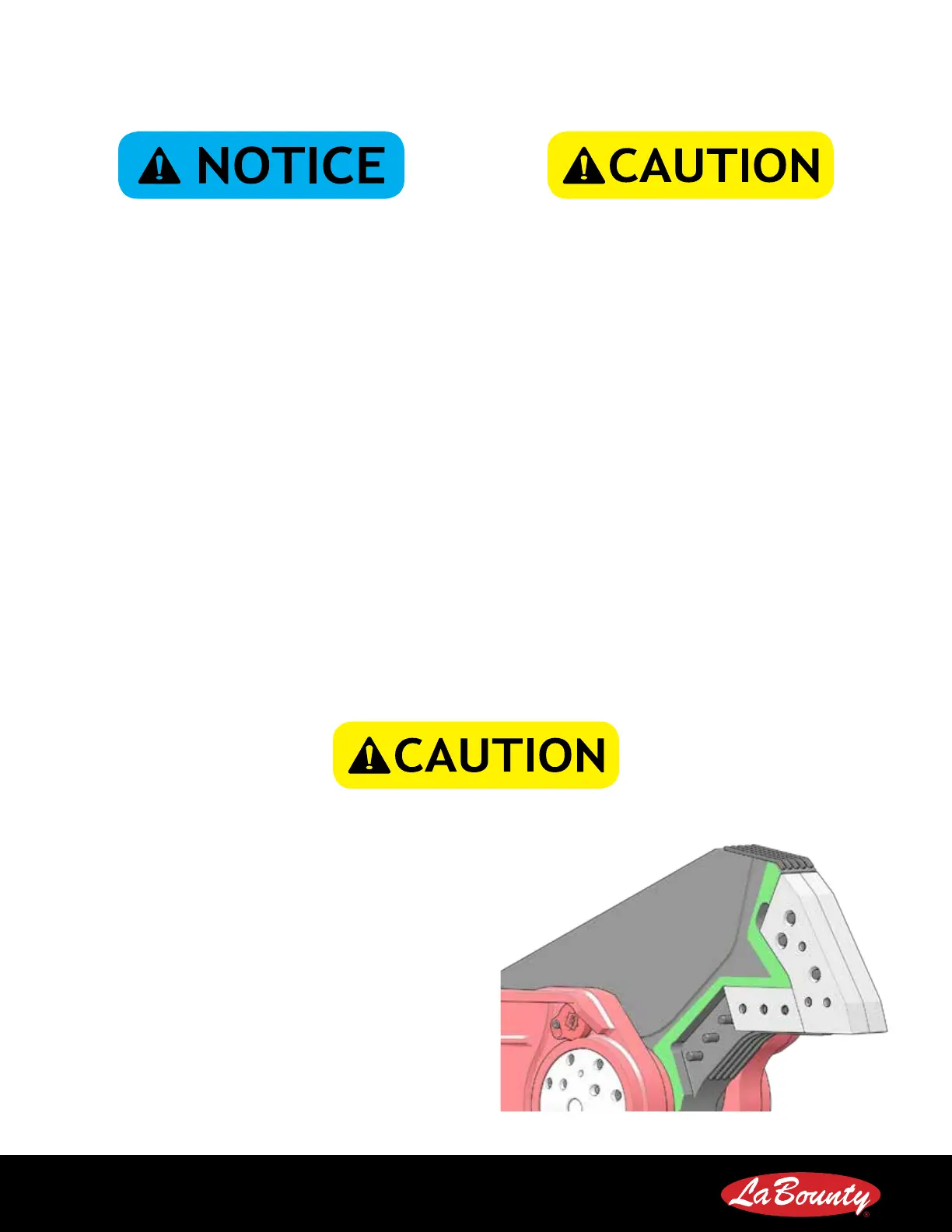

Build Up Example

FIGURE 30

Loading...

Loading...