Version 3.11 | HPI Combi Flow User Guide | 49www.lafert.com

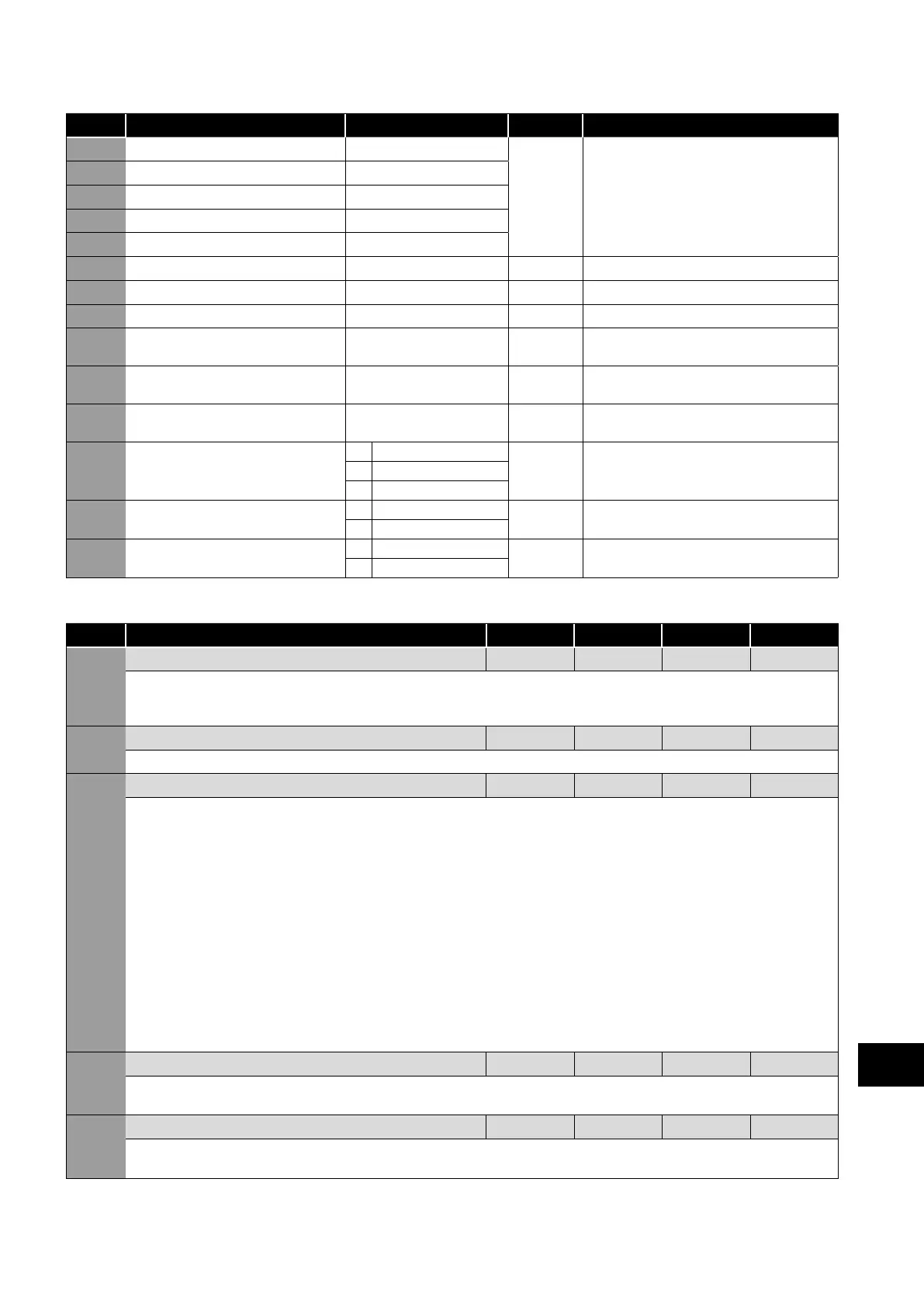

9.5.2. Parameter Group 7 – Motor Control

Par. Function Setting Range Default Notes

P7-01 Motor Stator Resistance

0.000 – 65.535

Motor

Rating

Dependent

Motor data, measured or calculated during

the autotune.

P7-06 is used only for PM motors.

P7-03 Motor Stator Inductance (d)

0.0000 – 1.0000

P7-04 Magnetising Current (id)

Drive Dependent

P7-05 Motor Leakage Coefficient (Sigma)

0.000 – 0.250

P7-06 Motor Q Axis Inuctance (Lsq)

0.0000 – 1.0000

P7-09 Over Voltage Current Limit 0.0 – 100.0% 5.0%

P7-10 Load Inertia Constant 0 - 600 10

P7-11 Pulse Width Minimum Limit 0 - 500

P7-12 V/F Mode Magnetising Delay Time 0 – 5000ms

Motor Rating

Dependent

Sets the motor alignment time in PM modes.

P7-14 Low Frequency Torque Boost 0.0 – 100.0%

Motor Rating

Dependent

For PM Motors, applies a torque boost current

at low frequency, % x P1-08.

P7-15 Torque Boost Frequency Limit 0.0 – 50.0%

Motor Rating

Dependent

For PM motors, determines the frequency, % x

P1-09 when the boost current is removed.

P7-18 Over Modulation

0 Disable

0

1 Enable

2 Auto

P7-19 BLDC Light Load Optimization

0 Disable

1

1 Enable

P7-20 Modulation Mode

0 3-Phase Modulation

1

1 2-Phase Modulation

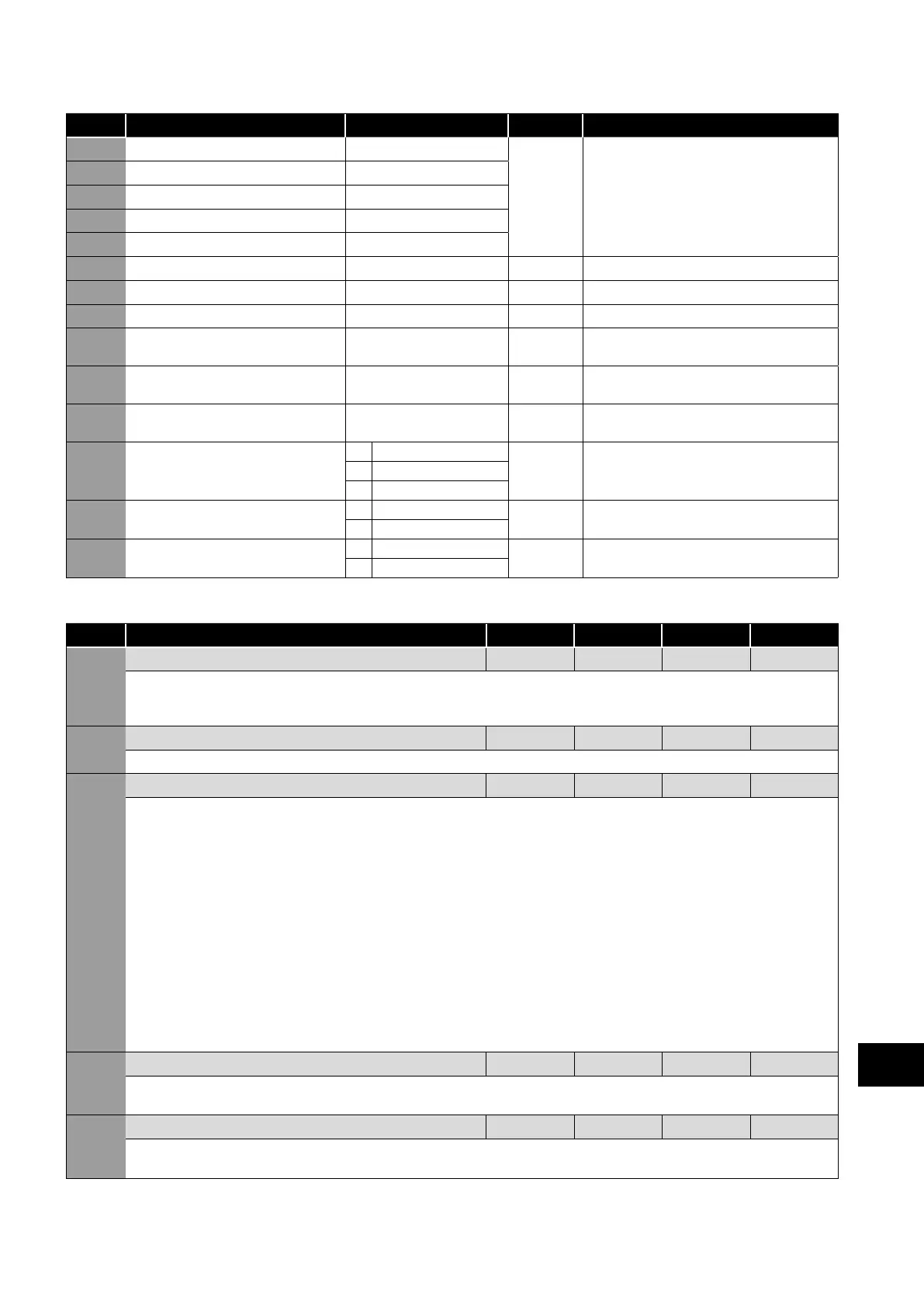

9.6. Parameter Group 8 – Application Function Specific Parameters

Par. Name Minimum Maximum Default Units

P8-01 Pump Stir Interval Duration 0 60000 0 Minutes

This parameter can be used to set a pre-defined period of inactivity, whereby if the drive remains in standby mode for a period of time

exceeding the limit, stir function is activated, and the drive will operate at preset speed 7 (P2-07) for the time set in P8-02. This allows

the pump to stir, preventing sediment from settling and avoiding a blockage.

P8-02 Pump Stir Activation Time 1 6000 10 Seconds

Set the time period that the stir function will be active once triggered (excludes time for deceleration to stop).

P8-03 Pump Clean Function Select 0 3 - -

This parameter configures the drive conditions that will cause activation of the automatic pump clean function. When activated, the

pump clean will operate the pump at preset speed 5 (P2-05) for the time period set in P8-04, followed by Preset Speed 6 (P2-06)

(Providing P2-06 <> 0) for the time set in P8-04, before resuming normal operation. During the cleaning cycle, the ramp time set in P8-

05 is used for both acceleration and deceleration, and overrides P1-03 and P1-04.

Where possible, P2-05 and P2-06 may be set to negative values, to allow the pump to be reversed. For best results, it is recommended

to use as high a speed as possible, and to adjust P8-05 to allow a short acceleration time whilst avoiding over current trips.

0 : Disabled.

1 : Active on start-up only. The pump cleaning function operates every time the pump is started.

2 : Active on start-up and high current detection. The pump cleaning function operates every time the pump is started,

and also in the event that the drive detects a possible pump blockage during normal operation. This requires the Motor Current Profile

Monitoring function to be active and commissioned for correct operation, see parameter P8-06.

3 : Active on high current detection only. The pump cleaning function operates only when a possible pump blockage is

detected during normal operation. This requires the Motor Current Profile Monitoring function to be active and commissioned for

correct operation, see parameter P8-06.

NOTE The pump clean function can also be activated by digital input configured in group 9 parameters.

P8-04 Pump Clean Time 0 600 0 Seconds

Sets the time period for the operation of the pump cleaning cycle. When bi-directional pump cleaning is selected, the time interval is

used twice, once in each direction.

P8-05 Pump Clean Function Ramp Time 0 6000 30 Seconds

Independent ramp rate used only for the pump automatic cleaning function (see P8-03) when the motor is Accelerated as part of the

cleaning cycle.

9

Extended Parameters

Loading...

Loading...