Launch TLT245AT / TLT250AT(C) Two-post lift user’s manual

6

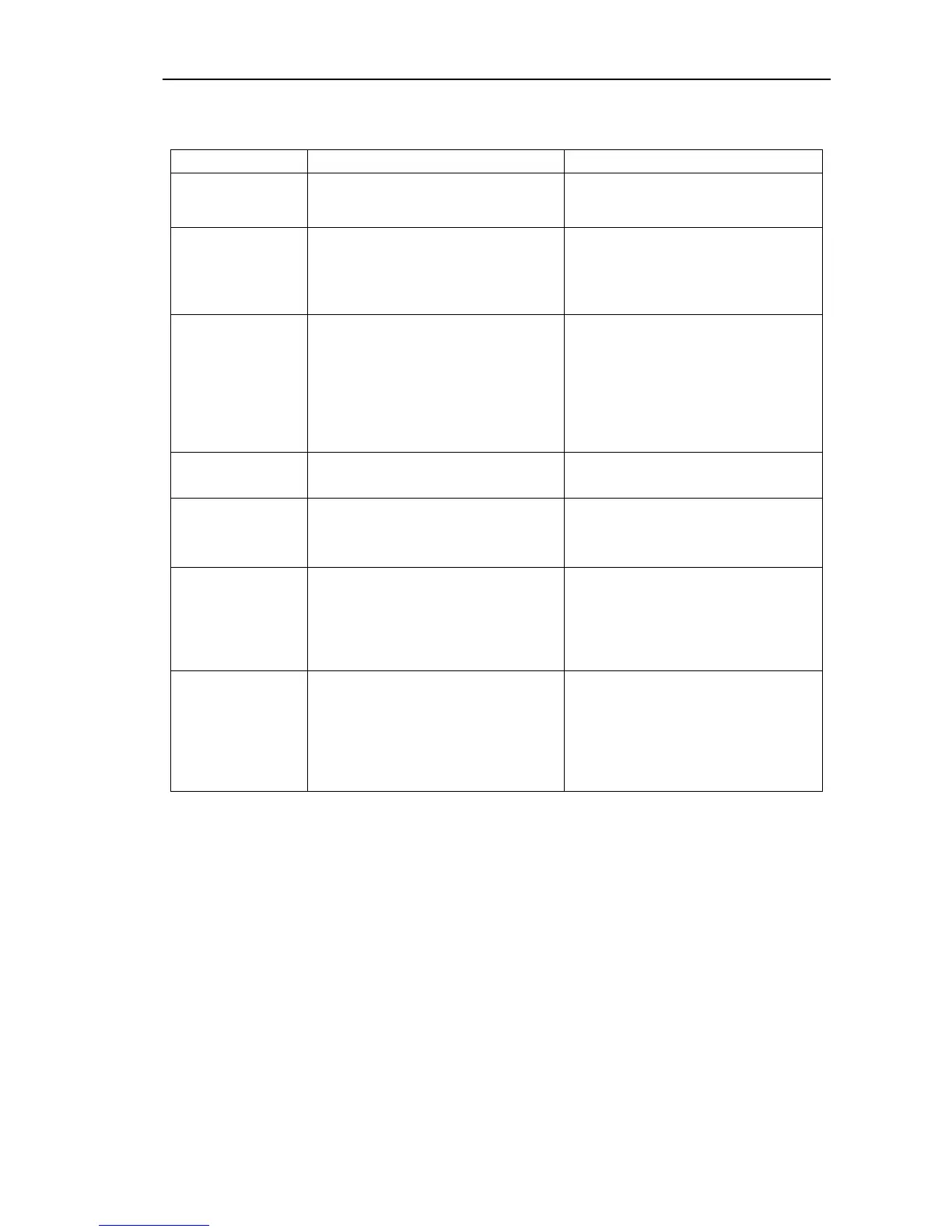

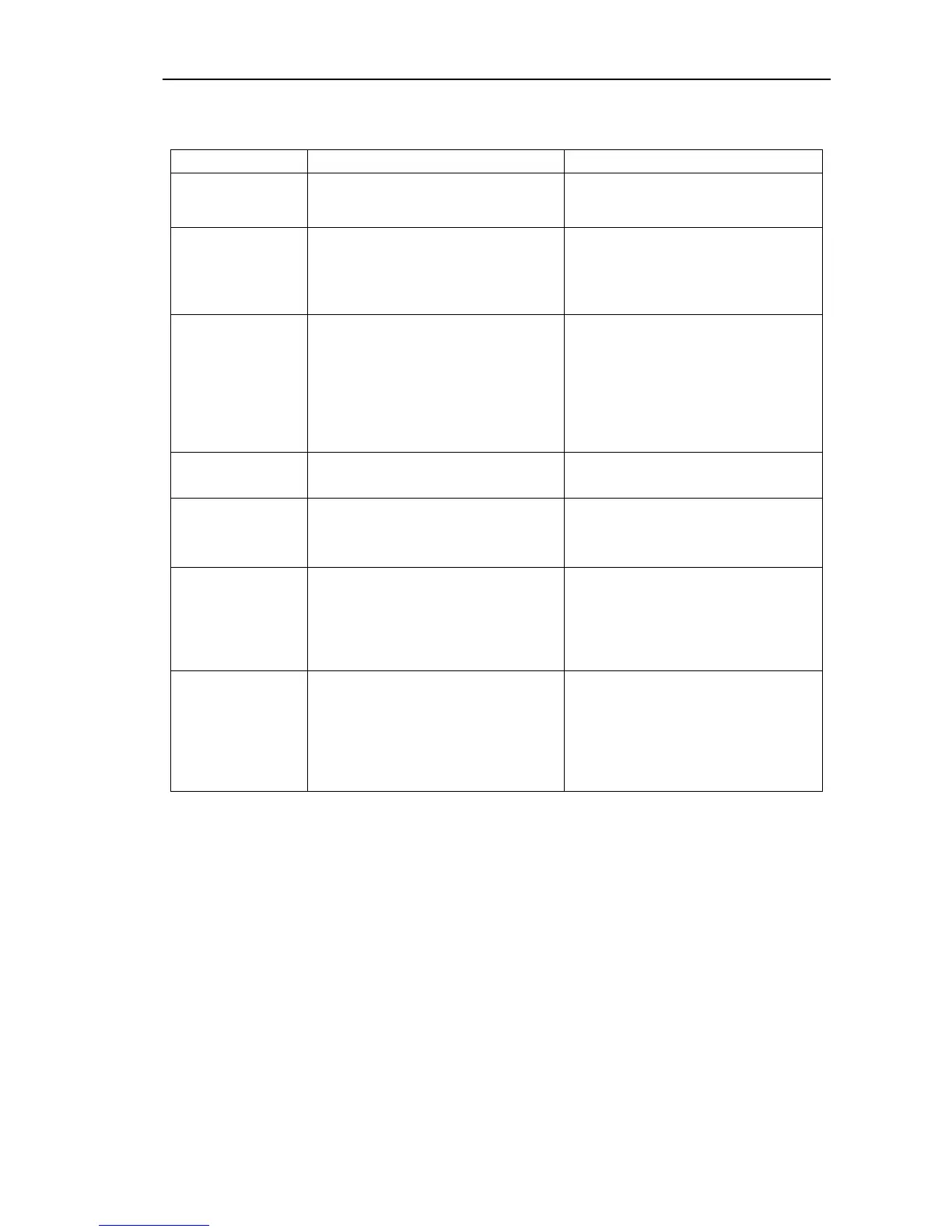

4. Solutions to FAQ

Symptom Reason Solution

Motor not operation

♦ Start-up button is broken

♦ Limit switch burnt out

♦ Motor burnt out

♦ Change UP button

♦ Change switch

♦ Change Motor

Motor is running, but

the lift can’t be raised.

♦ Hydraulic pump sucks the air

♦ Suction tube is separate from the

hydraulic pump

♦ Low oil level

♦ Fasten all the suction pipe fittings

♦ Replace the suction tube

♦ Add the oil into the oil tank

Motor is running, the

lift can be raised

without load, but the

vehicle can’t be raised

♦ Motor is running under low voltage

♦ Impurities inside the solenoid valve

body

♦ Regulation pressure of safety valve is

incorrect

♦ Lift is overloaded

♦ Supply correct voltage to the motor

♦ Remove impurities from the solenoid

valve body.

♦ Adjust the safety valve

♦ Check the weight of the vehicle

The lift is lowering

slowly

♦ Leakage on the solenoid valve body.

♦ External oil leakage

♦ Clean the solenoid valve body

♦ Repair the external leakage

The lifting speed is

slow or oil flows out of

the oil fill cap

♦ Air and oil are mixed

♦ Oil return pipe is loosened

♦ Replace the hydraulic oil or start when

air is out

♦ Re-install the oil return pipe

The lift can’t rise

horizontally

♦ Balance cable is not adjusted properly

♦ The lift is installed on the slop floor

♦ Adjust the balance cable to the proper

tension

♦ Shimming the columns to level the

lift(no more than 5mm), If exceeding

5mm, pour new concrete floor to make

it level. Refer to installation description.

Anchor Bolt is not

fastened

♦ Hole is drilled too big

♦ Concrete floor thickness or fastening

force is insufficient

♦ Pour the fast curing concrete into the

big hole and reinstall the anchor Bolt ,

or use new drill to drill the hole for

re-positioning the lift

♦ Cut open the old concrete and make

new concrete slab for the lift. Refer to

installation description.

Loading...

Loading...