DM442 Digital Stepping Drive Manual V1.0

Tel: +000 0000-00000000 28

installed on a machine. It is recommended that set low speed and small distance if you are not sure

whether the direction and distance is correct or not.

Procedure for Achieving Optimum Performance

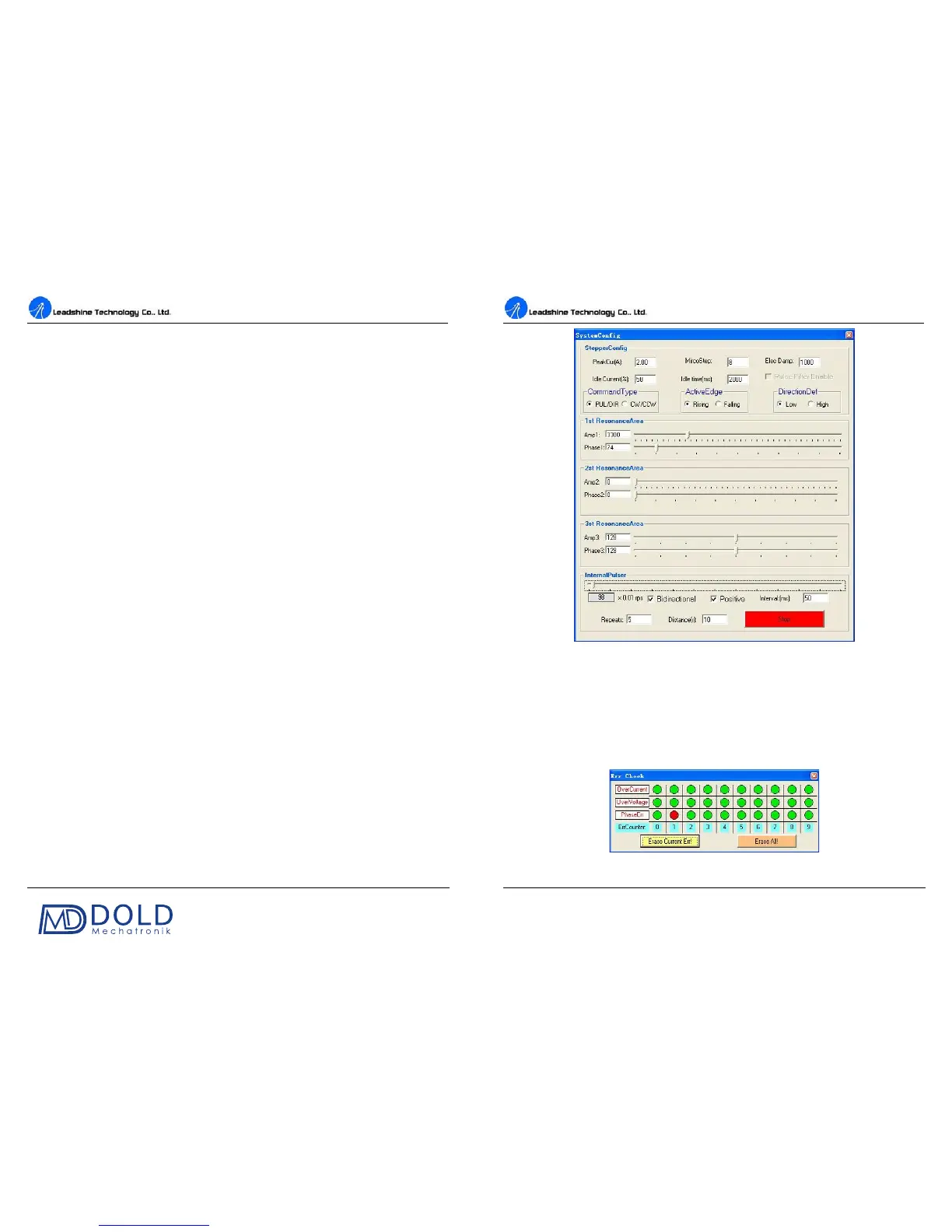

Step 1: Start the motion test by clicking Start/Stop button. Find a resonance speed by slightly moving

the slider bar of internal pulse generator back and forth. You can also use the arrow keys to adjust the

speed precisely.

St

ep 2: Run the motor at the resonance speed and verify the motor smoothness. You may find a better

smoothing value by slightly moving the slider bars of AMP(s) and Phase(s) back and forth.

It is very important to make the AMP(s) and Phase(s) adjustments at the proper test speeds with an

unloaded motor. Running at an incorrect test speed will not excite the motor at its peak resonance,

making it more difficult to find proper adjus

tment values. Optimum AMP(s) and Phase(s) values may

be a little different between running the tests with an unloaded motor and a load motor.

For example, we find a resonance speed at 0.98 rps. We begin to move the Amp1 slider forth and the

motor vibration and noise became lower and lower. Finally we find the move is the smoothest when

Amp 1 is 3300. The motor vibration and noise increase if Amp 1 exceeds 3300. Then we follow t

he

same procedure to search the best point for Phase 1. See Figure 26. Anti-resonance tuning is done.

Please remember to click Write EEprom to write the final parameter settings to the drive when finish

tuning.

DM442 Digital Stepping Drive Manual V1.0

Tel: +000 0000-00000000 29

Figure 26: 1

st

Anti -Resonance Tuning (Speed=0.98rps)

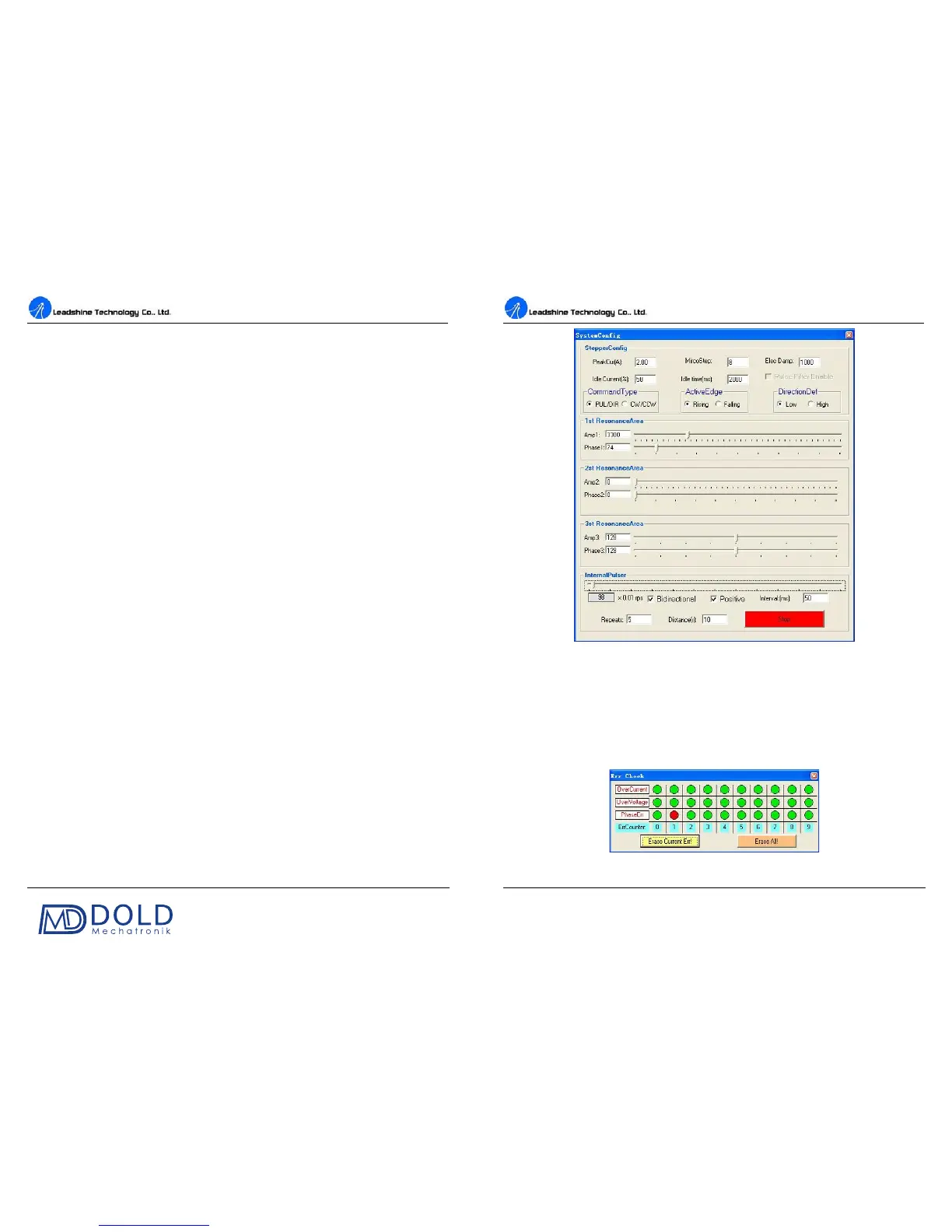

Err_check

Error Check: This window shows both the present status of each error event and their history.

Current error event(s) can be reset by clicking Erase Current Err! button, and all error events

can be reset by clicking Erase All! button. List of the last ten drive faults. #0 being the most

recent, #9 is the oldest. See Figure 27.

Figure 27: Error check window

Loading...

Loading...