DM442 Digital Stepping Drive Manual V1.0

Tel: +000 0000-00000000 10

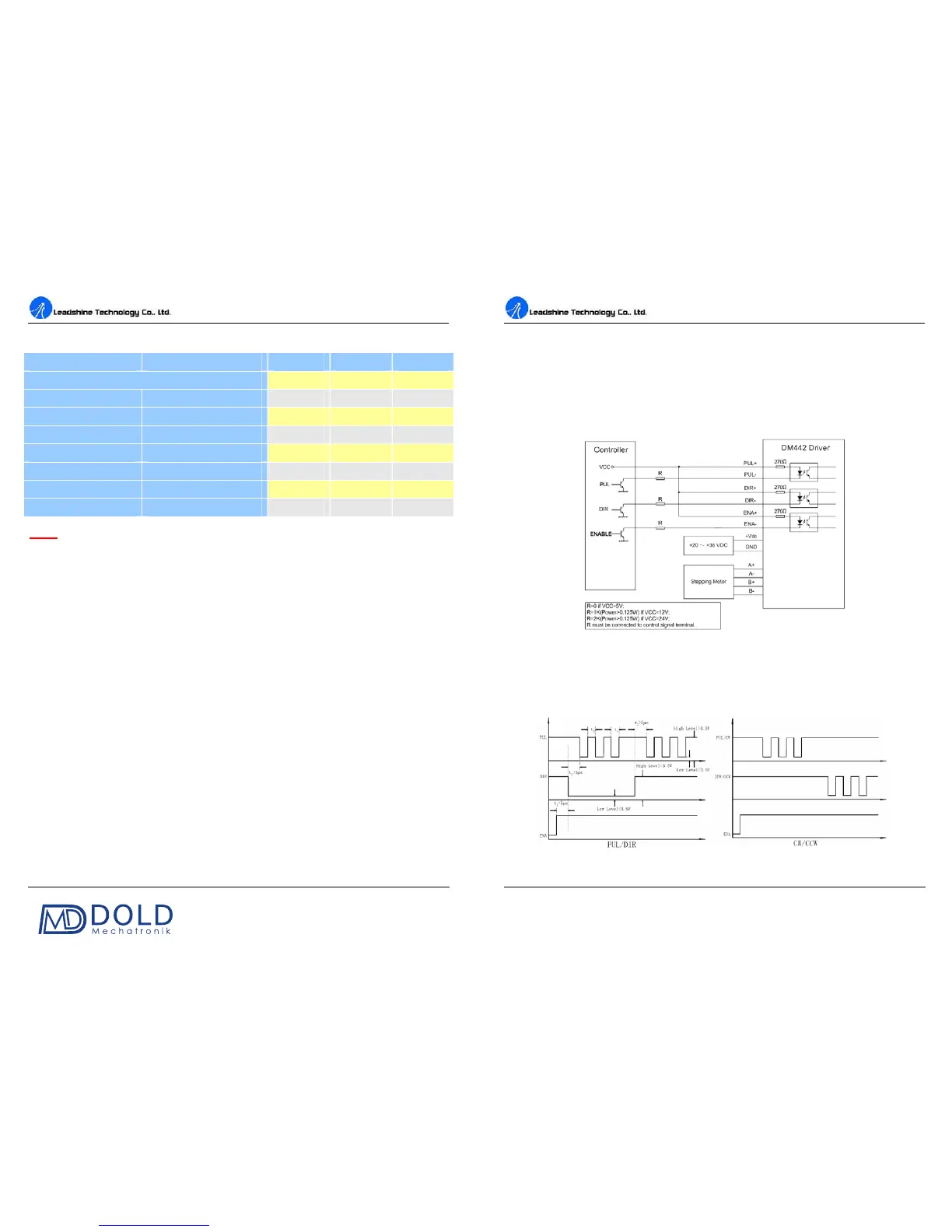

Dynamic current setting

Peak Current RMS Current SW1 SW2 SW3

Default/Software configured (0.5 to 4.2A) ON ON ON

1.46A 1.04A

OFF ON ON

1.91A 1.36A

ON OFF ON

2.37A 1.69A

OFF OFF ON

2.84A 2.03A

ON ON OFF

3.31A 2.36A

OFF ON OFF

3.76A 2.69A

ON OFF OFF

4.20A 3.00A

OFF OFF OFF

Notes: Due to motor inductance, the actual current in the coil may be smaller than the dynamic

current setting, particularly under high speed condition.

Standstill current setting

SW4 is used for this purpose. OFF meaning that the standstill current is software configured, and ON

meaning that standstill current is set to be the same as the selected dynamic current.

By default, the current automatically reduced to 60% of the selected

dynamic current two second

after the last pulse. Theoretically, this will reduce motor heating to 36% (due to P=I

2

*R) of the

original value. Reduction rate and idle time can be configured in the PC software ProTuner. See

more information in section 13.

8. Wiring Notes

In order to improve anti-interference performance of the drive, it is recommended to use twisted

pair shield cable.

To prevent noise incurred in PUL/DIR s

ignal, pulse/direction signal wires and motor wires

should not be tied up together. It is better to separate them by at least 10 cm, otherwise the

disturbing signals generated by motor will easily disturb pulse direction signals, causing motor

position error, system instability and other failures.

If a power supply serves several drives, separately connecting the drives is recommended

instead of daisy-chaining.

It

is prohibited to pull and plug connector P2 while the drive is powered ON, because there is

DM442 Digital Stepping Drive Manual V1.0

Tel: +000 0000-00000000 11

high current flowing through motor coils (even when motor is at standstill). Pulling or plugging

connector P2 with power on will cause extremely high back-EMF voltage surge, which may

damage the drive.

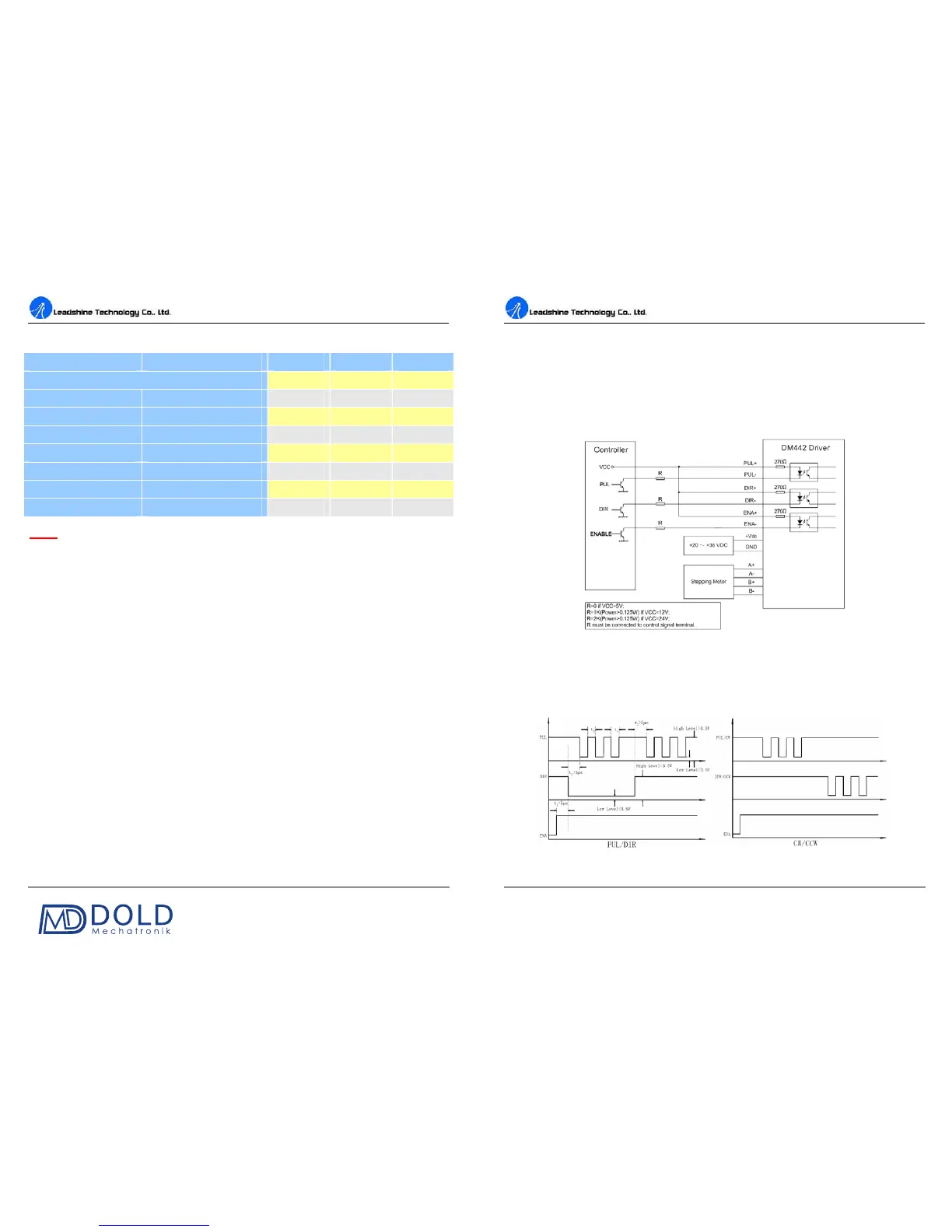

9. Typical Connection

A complete stepping system should include stepping motor, stepping drive, power supply and

controller (pulse generator). A typical connection is shown as figure 9.

Figure 9: Typical connection

10. Sequence Chart of Control Signals

In order to avoid some fault operations and deviations, PUL, DIR and ENA should abide by some

rules, shown as following diagram:

Figure 10: Sequence chart of control signals

Loading...

Loading...