DM442 Digital Stepping Drive Manual V1.0

Tel: +000 0000-00000000 4

Selecting Active Pulse Edge and Control Signal Mode

The DM442 supports PUL/DIR and CW/CCW modes and pulse actives at rising or falling edge. See

more information about these settings in Section 13. Default setting is PUL/DIR mode and rising

edge active (NPN, and PNP control signal is on the contrary).

Connector P2 Configurations

Pin Function Details

+Vdc Power supply, 20~40 VDC, Including voltage fluctuation and EMF voltage.

GND Power Ground.

A+, A- Motor Phase A

B+, B- Motor Phase B

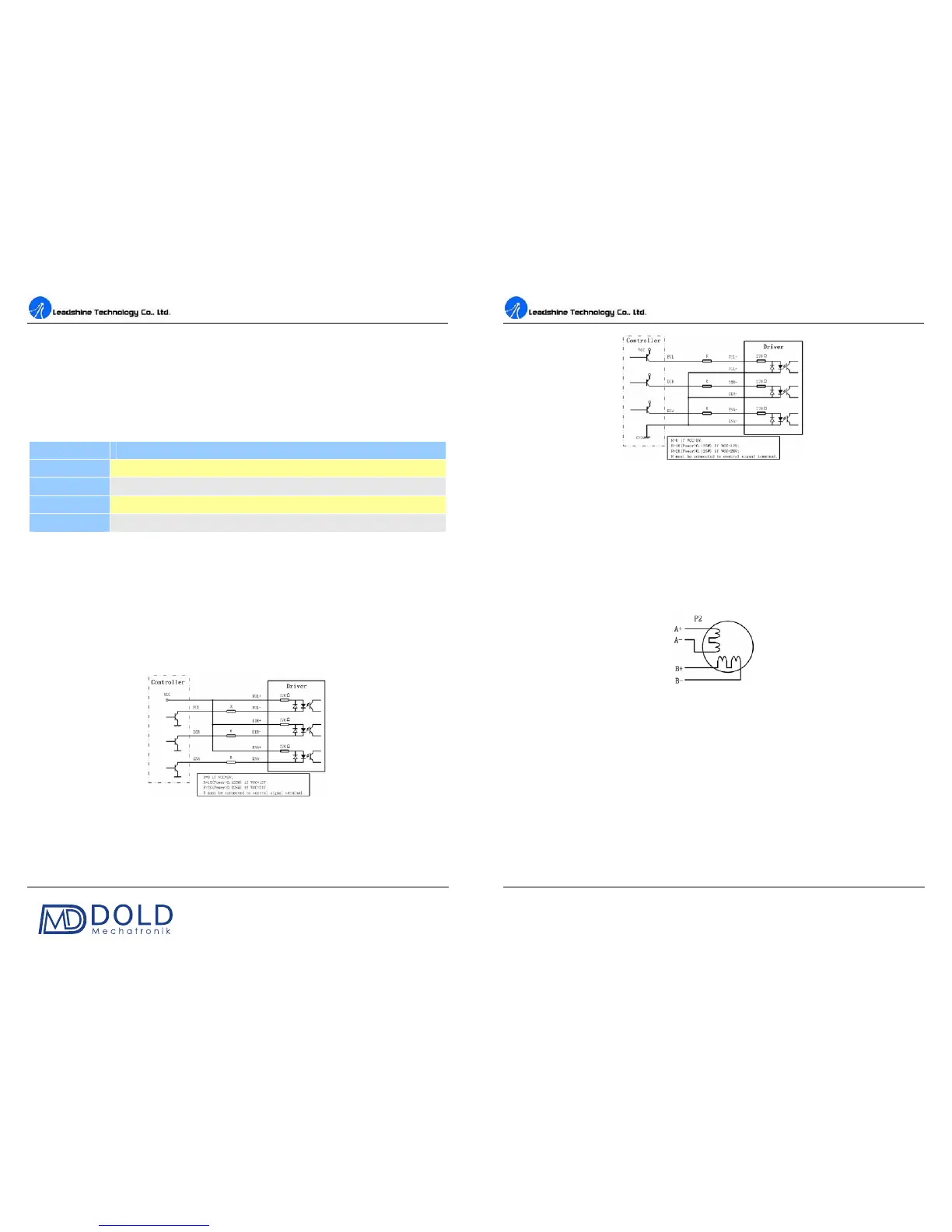

4. Control Signal Connector (P1) Interface

The DM442 can accept differential and single-ended inputs (including open-collector and PNP

output). The DM442 has 3 optically isolated logic inputs which are located on connector P1 to accept

line drive control signals. These inputs are isolated to minimize or eliminate electrical noises coupled

onto the drive control signals. Recommend use line drive control signals to increase noise

immunity

of the drive in interference environments. In the following figures, connections to open-collector and

PNP signals are illustrated.

Figure 2: Connections to open-collector signal (common-anode)

DM442 Digital Stepping Drive Manual V1.0

Tel: +000 0000-00000000 5

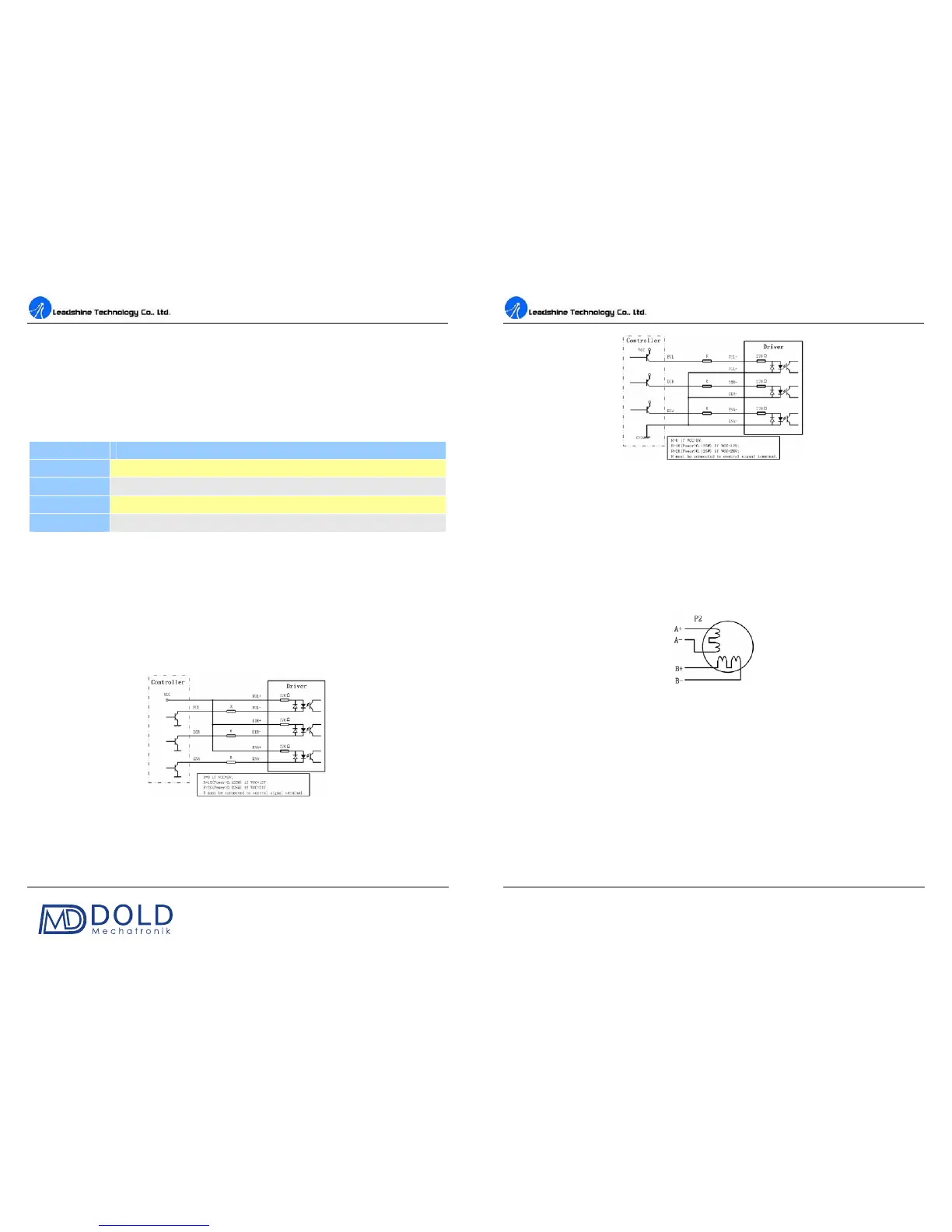

Figure 3: Connection to PNP signal (common-cathode)

5. Connecting the Motor

The DM442 can drive any 2-phase and 4-phase hybrid stepping motors.

Connections to 4-lead Motors

4 lead motors are the least flexible but easiest to wire. Speed and torque will depend on winding

inductance. In setting the drive output current, multiply the specified phase current by 1.4 to

determine the peak output current.

Figure 4: 4-lead Motor Connections

Connections to 6-lead Motors

Like 8 lead stepping motors, 6 lead motors have two configurations available for high speed or high

torque operation. The higher speed configuration, or half coil, is so described because it uses one half

of the motor’s inductor windings. The higher torque configuration, or full coil, uses the full windings

of the phases.

Half Coil Configurations

As previously stated, t

he half coil configuration uses 50% of the motor phase windings. This gives

lower inductance, hence, lower torque output. Like the parallel connection of 8 lead motor, the torque

output will be more stable at higher speeds. This configuration is also referred to as half chopper. In

Loading...

Loading...