26

If malfunction is still present, contact service centre.

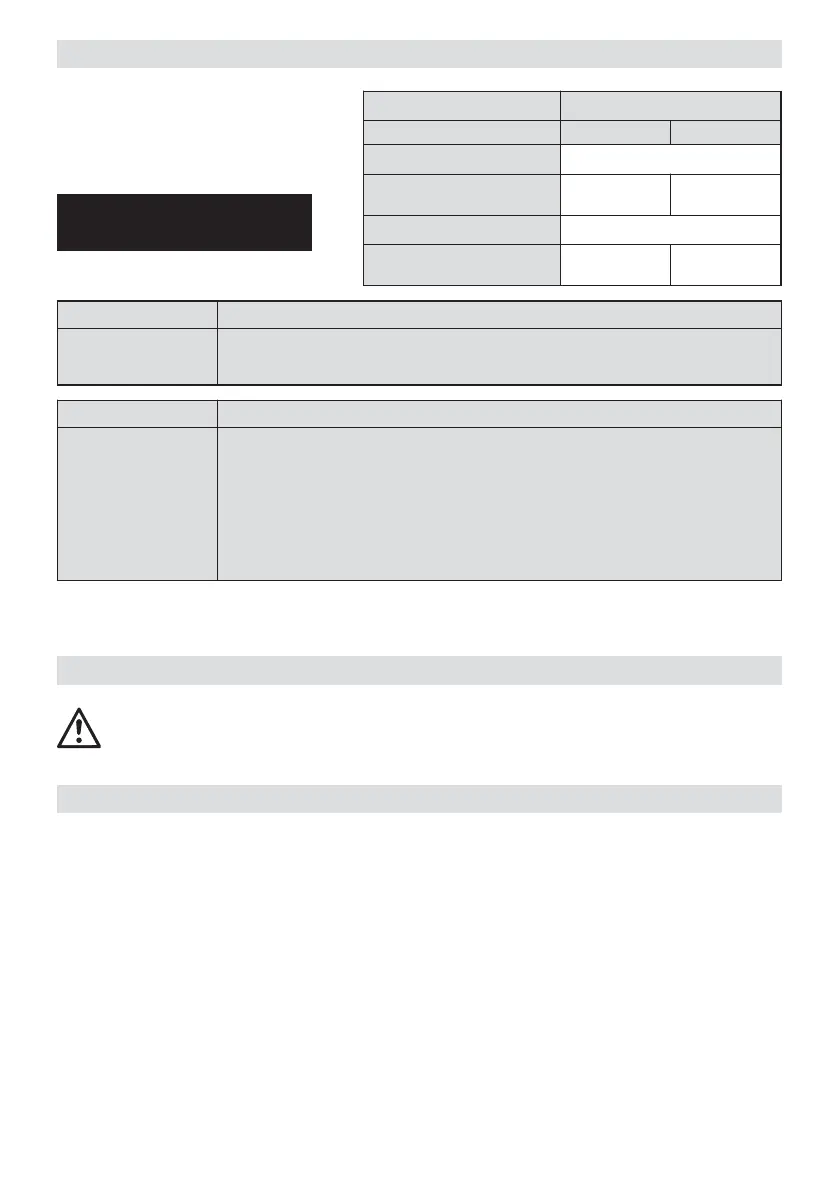

< Overload Indication

*

Heating / Drive active

Check the welding process and identify

faults by means of the display of power

consumption.

Operating conditions

Display no. Level

Drive / heating Main Control

1. Welding speed ACTUAL value

2. Welding speed SET value

Power

consumption

3. Temperature ACTUAL value

4. Temperature SET value

Power

consumption

Display 4 Heating reason for fault after heating up time

100 %

100 %

• mains under-voltage

• heating cartridges faulty

Display 2 Drive reason for fault

100 %

100 % or <

100 % or <

100 % or <

100 % or <

• mains under-voltage

• overlap of the geomembrane liner too wide

• dirt on the drive rollers (20/21)

• max. welding pressure (1000 N) has been exceeded

• high welding speed with large sudden overload

(ie anchoring trench, T-joints....)

Perform a test welding according to the welding instructions of the material manufacturer

and the national standards or guidelines. Check the test welding.

• Drive/pressure rollers (20/21), idler wheel (28), lower guide plate (30) and upper guide plate (29) as well

as the hot wedge (7) must be clean.

• Film and sealing membranes must be clean between the overlap and on the upper and lower surfaces.

• Length of the power supply cord/cable guide.

Check

Test weld

Loading...

Loading...