31

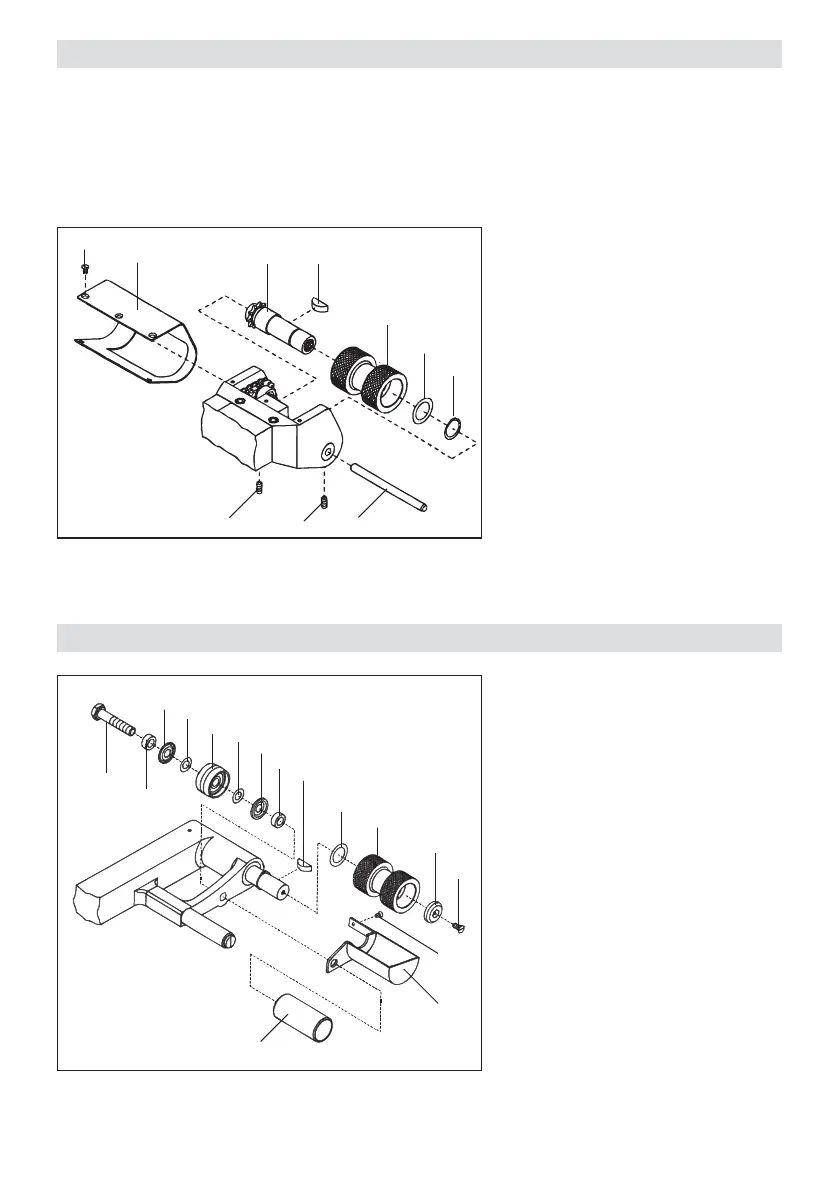

Dismantling of the drive/pressure rollers, sequence 1 – 16

Assembly of the drive/pressure rollers, reverse 16 – 1

1 Countersunk screw M3 × 6

2. Cylinder screw M8 × 40

3 Spacer bush

4 Nilos-ring ø 8/20 × 1,8

5 Shim ø 8/14 × 0,1

6. Rear travelling wheel complete

7 Shim ø 8/14 × 0,1

8 Nilos-ring ø 8/20 × 1,8

9 Spacer bush

10 Guide roller

11 Guard plate drive/pressure roller

12 Countersunk screw M4 × 12

13 Locking washer

14 Drive/pressure roller

15 Spacer ø 15/22 × 0,3

16 Woodruff key 5 × 6,5

10

1

11

16

15

14

13

12

9

8

2

3

4

5

6

7

For various applications, for example tunnel construction or civil engineering at or below ground level, various

overlap-welded seams can be manufactured with the LEISTER Comet. These differ in the width of the welded

seam and the width of the test channel. Also welded seams without a test channel can be manufactured. In

order to implement these different overlapped seams, the appropriate drive/pressure rollers must be fixed.

These drive/pressure rollers can be produced in aluminium or stainless steel according to the customer’s

requirements.

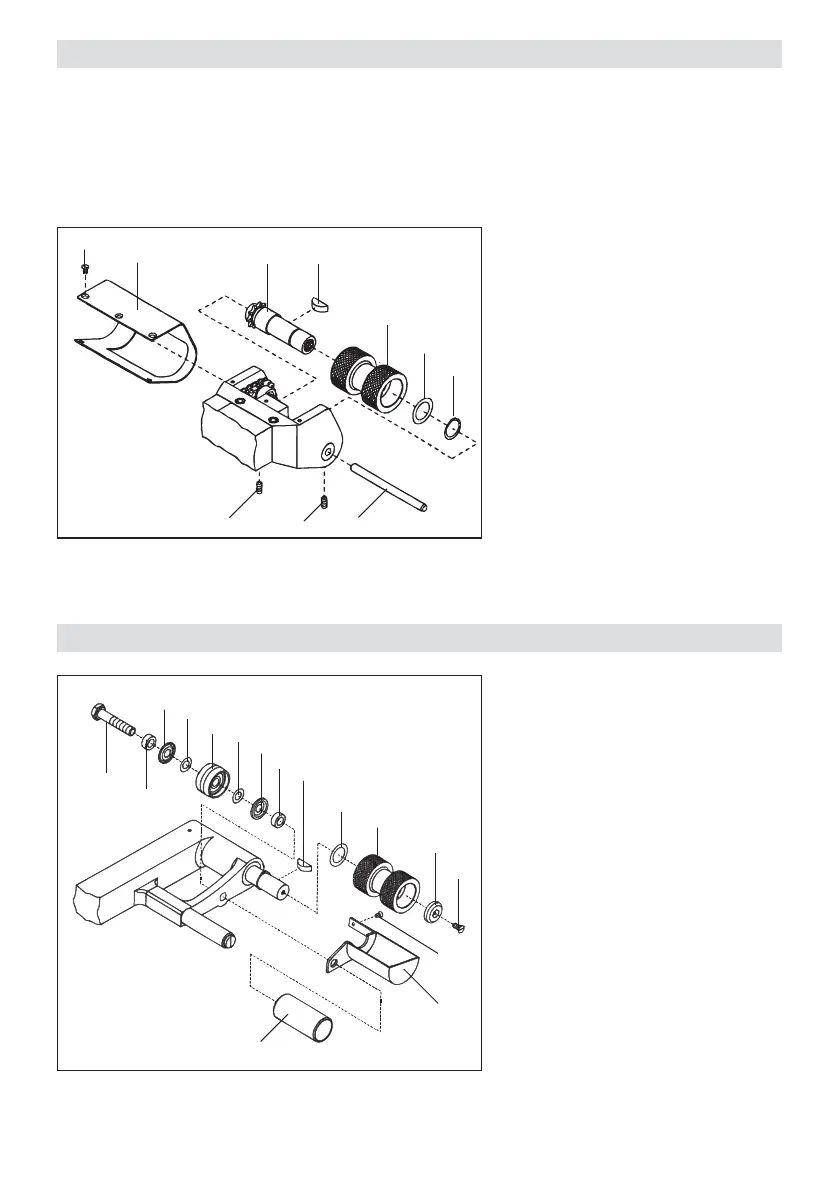

Dismantling of the drive pressure rollers, sequence 1 – 9

Assembly of the drive/pressure rollers, reverse order 9 – 1

1 Countersunk screw M3 × 6

2 Guard plate for swivelling head

3 Set screw M4 × 8

4 Straight pin 6 × 80

5 Locking ring (shaft ø 15)

6 Spacer ring

7. Drive/pressure roller

8 Woodruff key

9 Drive shaft, upper complete

1

2

9 8

7

6

5

3

3

4

Changeover of upper drive / pressure roller

Changeover of lower drive / pressure roller

Loading...

Loading...