14

MAINTENANCE (DC-2000, DC-3100, DC-4600 & DC-7700)

SPRAY GUN:

The filter should be cleaned or replaced after each use to minimize tip

clogging problems. If the gun valve becomes worn and begins to leak, it

should be replaced. See L-65 section for overhaul details.

SPRAY TIP:

The spray tip is one of the most important elements in producing a

quality spray job. It requires periodic replacement (every 50-200 gallons)

to maintain performance and to prevent overworking the pump (see Tip

Selection section for details).

LOWER PACKINGS:

No regular service required.

The lower packings of these units are stationary, so that the only metal

wearing parts are the valves and the piston. Costly replacement of the

pump cylinder is eliminated. The lower packings are self adjusting, and

will generally outlast the upper packings. Both sets are included in the

packing kit, and should be changed together for best reliability and

performance. On the DC-7700 the lower packings can be re-thightened

after every 2000 gallons of paint has been sprayed. Simply rotate the

inlet valve housing 1/8 of a turn clockwise to adjust the spring tension on

the packings.

UPPER PACKINGS:

Lubricate daily with 2 to 3 drops of L034-125 oil. Oiling location is shown

on pages 6 & 7. The upper packings are adjusted manually, by turning

the brass packing nut to the left, ie; clockwise as viewed from the top.

Keep guard in place during operation.

IMPORTANT NOTE: The packings should never be over tightened,

as this greatly reduces packing and piston life. Never tighten

packings with pressure in unit, as a false indication of adjustment

will result. A bit of gummy buildup around the packing nut is

normal and should be periodically removed with a brush and

solvent. This allows lubricant oil to reach packings.

NOTE: Do not adjust packing while unit is running. Fingers, tools,

etc. can be trapped between plunger and packing nut. Loss of

finger or serious injury could result.

TO TIGHTEN UPPER PACKINGS:

1) Turn unit off, ensure prime valve is open, and all pressure is

relieved. Unplug from electrical outlet.

2) Remove all buildup from around packing nut.

3) Using a hammer and srewdriver, turn packing nut clockwise a

maximum of 1/8 turn. Packings should be only tightened just enough

to stop leakage. See notice above. Gentle tightening is normally

sufficient.

4) Lubricate packings using L034-125 oil.

5) Replace safety shield over packing area.

NOTE: When no further adjustment of packings is possible, the

nut will be difficult to turn with reasonable effort. Packings should

be replaced.

CHECK VALVES:

These pumps have two valves, the footvalve at the paint inlet, and the

shaft valve in the bottom of the piston. Both are of stainless steel ball,

tungsten seat construction. This means that inexpensive, easily

replaced balls are the normal wear point. If the unit will not draw up

paint, the footvalve may be stuck. Simply tapping on the side of the

footvalve with a wooden block will usually suffice. Should this not work,

the following pages will show you how to remove and clean the

footvalve and check the shaft valve.

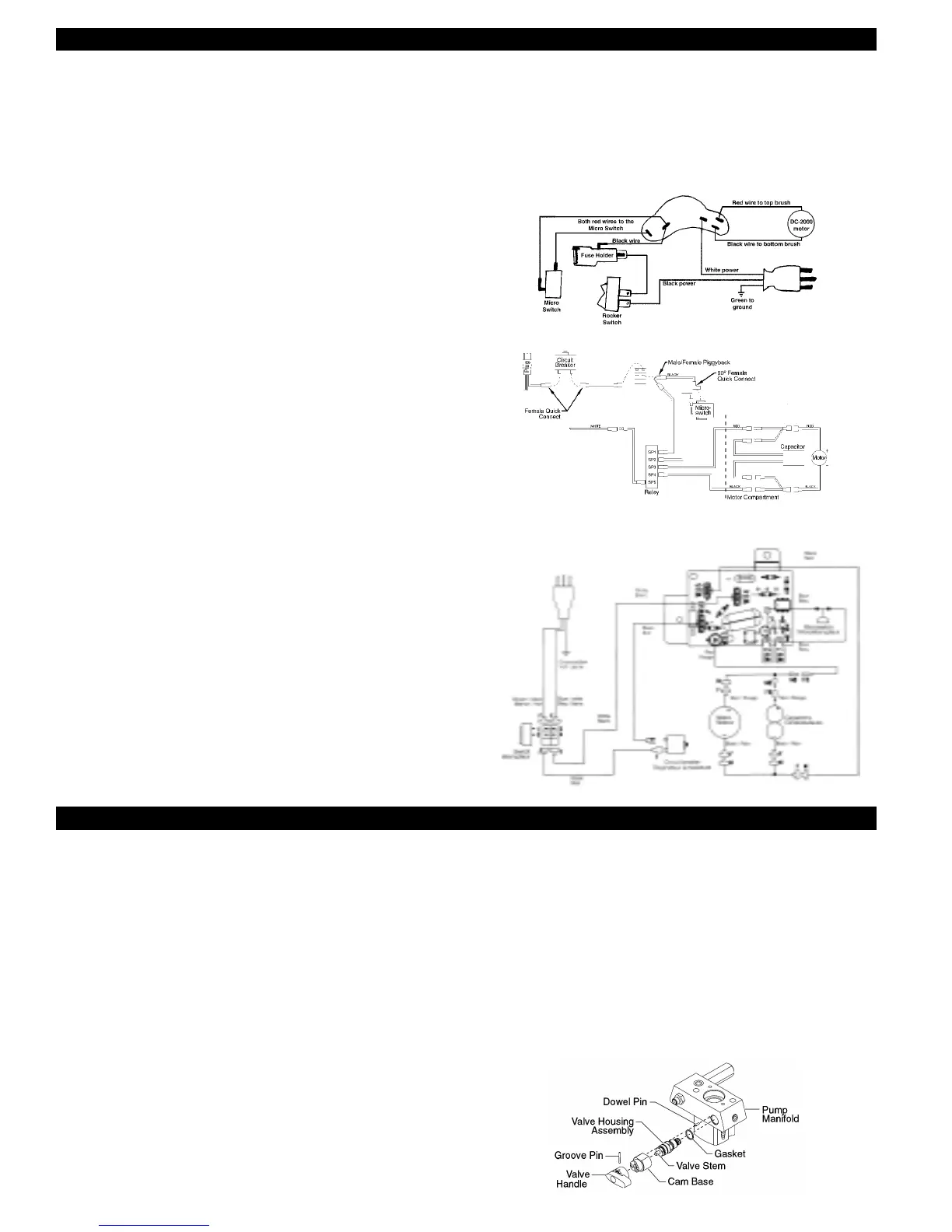

Wiring diagram, DC-2000

SERVICE (DC-3100)

Wiring diagram, DC-3100

MAINTENANCE

Before proceeding, follow the Pressure Relief Procedure outlined

previously in this manual. Additionally, follow all other warnings to

reduce the risk of an injection injury, injury from moving parts or

electric shock. Always unplug the sprayer before servicing!

GENERAL REPAIR AND SERVICE NOTES

1) Before repairing any part of the sprayer, read the instructions

carefully, including all warnings. Never pull on a wire to disconnect

it. Pulling on a wire could loosen the connector from the wire.

2) Test your repair before regular operation of the sprayer to be sure

that the problem is corrected. If the sprayer does not operate

properly, review the repair procedure to determine if everything was

done correctly. Refer to the Troubleshooting section to help identify

other possible problems.

3) Make sure that the service area is well ventilated in case solvents

are used during cleaning. Always wear protective eyewear while

servicing. Additional protective equipment may be required depend-

ing on the type of cleaning solvent. Always contact the supplier of

solvents for recommendations.

4) If you have any further questions concerning your LEMMER Airless

Sprayer, call one of our locations listed in the back of this manual.

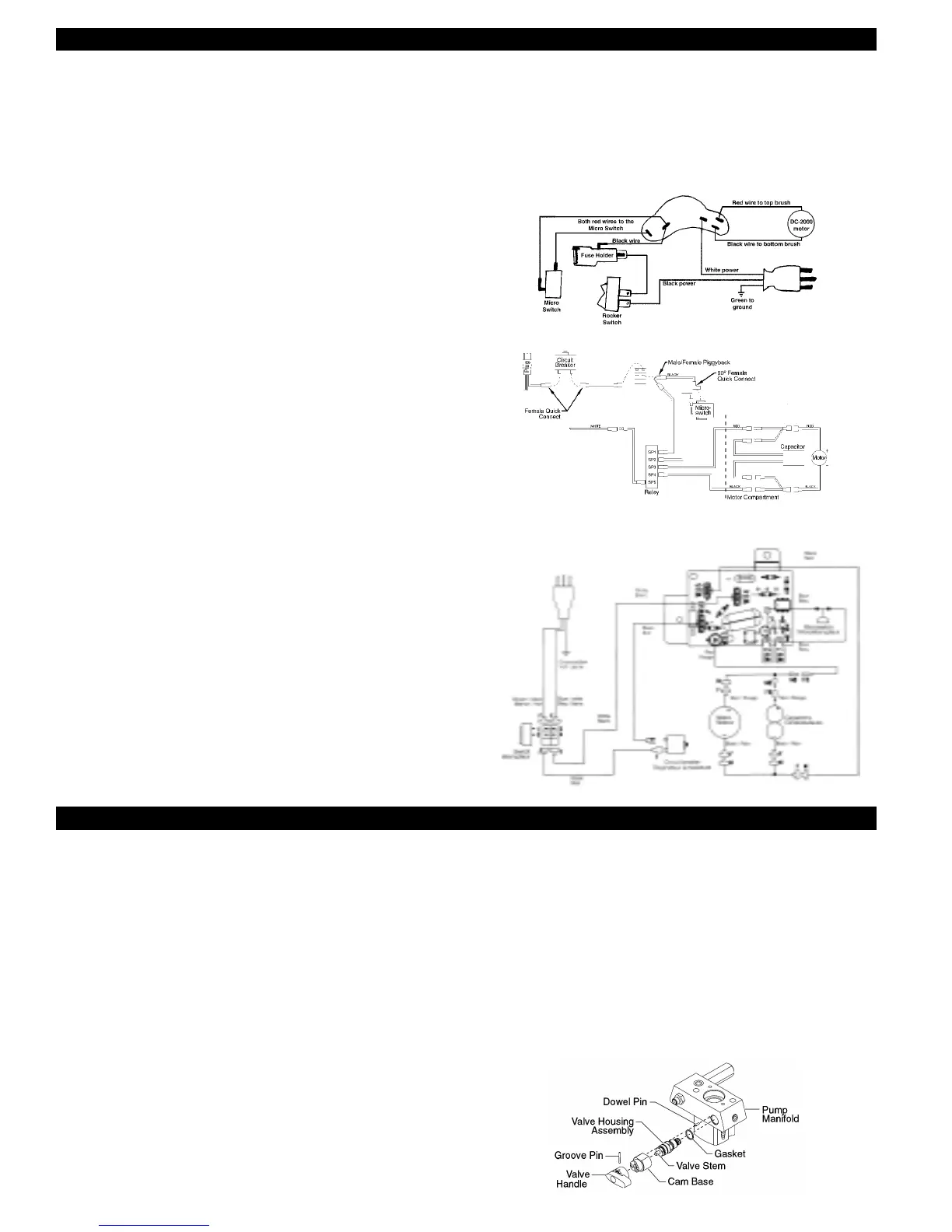

REPLACING THE PRIME/SPRAY VALVE

Perform the following procedure using PRIME/SPRAY valve replace-

ment kit P/N L045-862.

1) Drive the groove pin out of the valve handle.

2) Remove the valve handle and the cam base.

3) Using a wrench, loosen and remove the valve housing assembly

from the pump manifold.

4) Make sure the gasket is in place and thread the new valve housing

assembly into the pump manifold. Tighten securely with a wrench.

5) Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam with the pump

manifold using the dowel pin.

6) Line up the hole on the valve stem with the hole in the valve handle.

7) Insert the groove pin into the valve handle and through the valve

stem to secure the valve handle in position.

Wiring diagram, DC-3100N

Loading...

Loading...