7

SETTING UP OF UNIT

TOOLS NEEDED:

2 x 8" or larger crescent wrench

PROCEDURE:

1) Remove all system components from the box for assembly.

2) Remove protective cap from outlet connection of pump.

3) Connect high pressure airless paint hose to pump outlet. Tighten to

approximately 20 ft. lbs.

4) Attach the tip assembly to the spray gun.

5) Connect the paint hose to the swivel connection of the spray gun.

Tighten 20 ft lbs. Ensure the gun handle is securely hand tightened

to the gun.

6) Double check all connections, the unit is now ready.

Note: The pump contains a preservative oil when you receive it, that

may drip from the various connections when the protective caps are

removed.

WARNING: INJECTION HAZARD POSSIBLE. DO NOT SPRAY

WITHOUT TIP IN PLACE. ALWAYS ENGAGE TRIGGER LOCK

BEFORE REMOVING, REPLACING OR CLEANING TIP. NEVER TRY

TO CLEAN THE TIP WITH YOUR FINGERS.

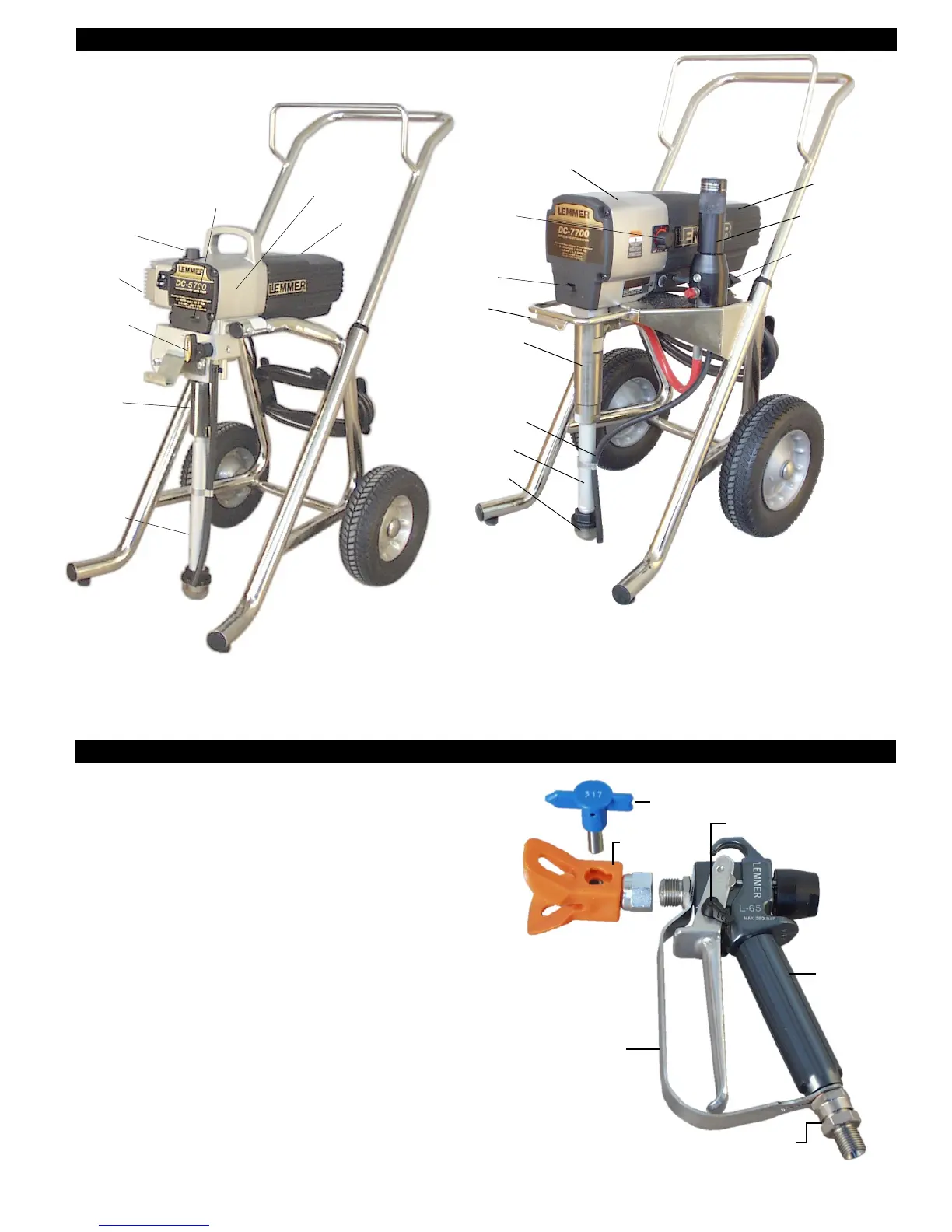

To disengage your trigger lock: Your spray gun is shipped from the

factory with the trigger lock in the engaged position (horizontal on

the L-65). To disengage, turn the trigger lock down until it is in a

vertical position. To engage the trigger lock, turn it back to a

horizontal position.

trigger lock.

Figure 2. - L-65 gun components.

gun handle

with filter

inside.

hand tight

only!

tip.

tip housing.

trigger guard

for safety. do

not remove!

high pressure

swivel, 1/4"npt.

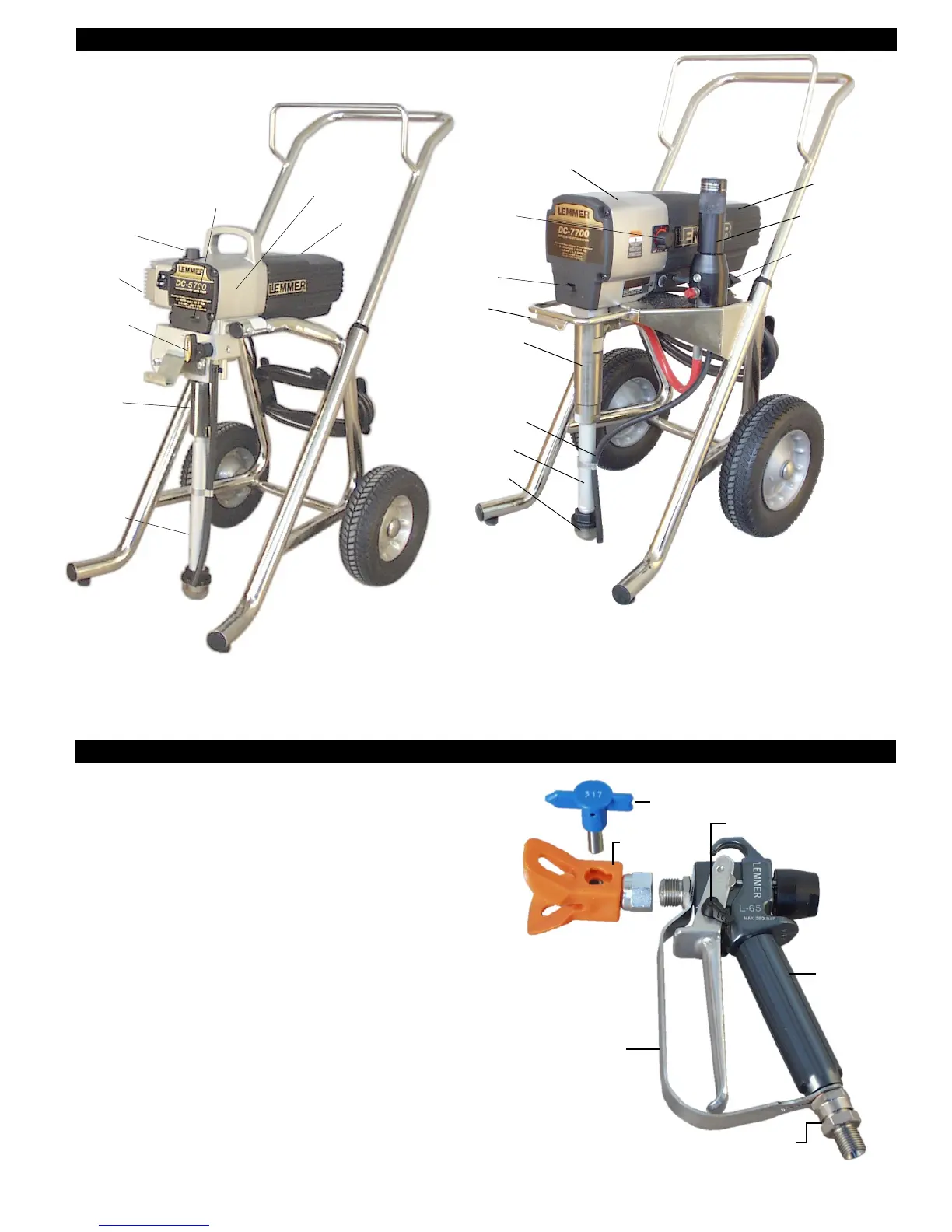

PUMP COMPONENTS

motor

pail hook

suction pipe

return hose

speed reducer

paint pump

suction screen

prime valve

pressure control

& on / off switch

High pressure filter

Figure 1e. - DC-7700 components.

Figure 1d. - DC-5700 components.

paint

pump

motor

pressure

control

speed reducer

prime

valve

suction

system

on / off

switch

2 to 3 drops

oil daily

2 to 3 drops

oil daily

Loading...

Loading...