Page 12

Then, apply the measurements taken in following formula

to determine CFM:

CFM =

Amps x Volts x 3.41

1.08 x Temperature rise (F)

SETUP FOR CHARGING

Connect the manifold gauge set to the unit’s service ports.

S

low pressure gauge to vapor service port

S

high pressure gauge to liquid service port

Close manifold gauge set valves. Connect the center man-

ifold hose to an upright cylinder of HFC−410A.

CALCULATING CHARGE

If the system is void of refrigerant, first, locate and repair

any leaks and then weigh in the refrigerant charge into the

unit. To calculate the total refrigerant charge:

Amount

specified

on

nameplate

Adjust amt. for

variation in line set

length (table in

figure 6)

Additional charge

specified per indoor

unit matchup tables.

To tal

charge

+ + =

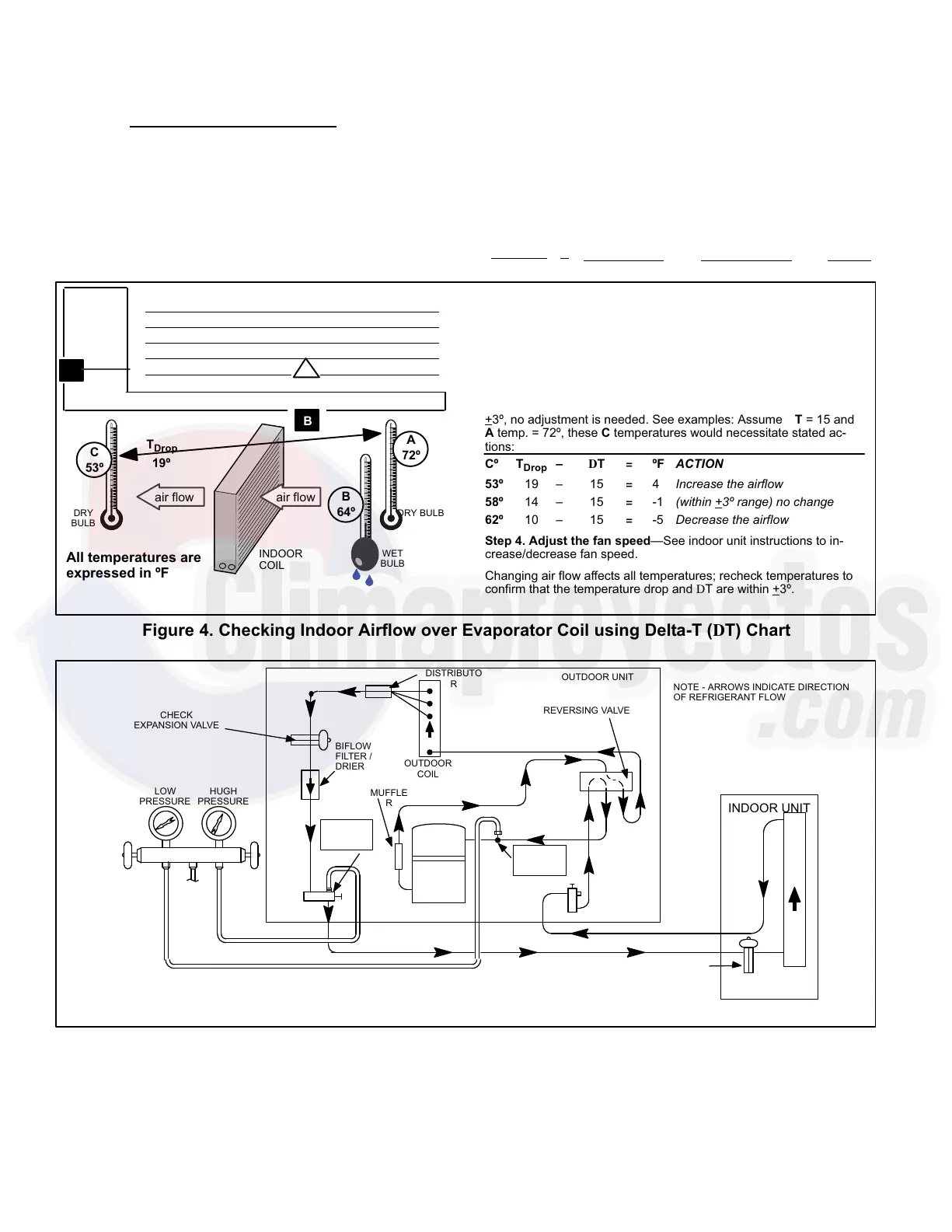

Step 1. Determine the desired DTMeasure entering air tempera-

ture using dry bulb (A) and wet bulb (B). DT is the intersecting value

of A and B in the table (see triangle).

Step 2. Find temperature drop across coilMeasure the coil’s dry

bulb entering and leaving air temperatures (A and C). Temperature

Drop Formula: (T

Drop

) = A minus C.

Step 3. Determine if fan needs adjustmentIf the difference be-

tween the measured T

Drop

and the desired DT (T

Drop

–DT) is within

+3º, no adjustment is needed. See examples: Assume DT = 15 and

A temp. = 72º, these C temperatures would necessitate stated ac-

tions:

Cº T

Drop

– DT = ºF ACTION

53º 19 – 15 = 4 Increase the airflow

58º 14 – 15 = −1 (within +3º range) no change

62º 10 – 15 = −5 Decrease the airflow

Step 4. Adjust the fan speedSee indoor unit instructions to in-

crease/decrease fan speed.

Changing air flow affects all temperatures; recheck temperatures to

confirm that the temperature drop and DT are within +3º.

DT

80 24 24 24 23 23 22 22 22 20 19 18 17 16 15

78 23 23 23 22 22 21 21 20 19 18 17 16 15 14

76 22 22 22 21 21 20 19 19 18 17 16 15 14 13

74 21 21 21 20 19 19 18 17 16 16 15 14 13 12

72 20 20 19 18 17 17 16 15 15 14 13 12 11 10

70 19 19 18 18 17 17 16 15 15 14 13 12 11 10

57 58 59 60 61 62 63 64 65 66 67 68 69 70

Temp.

of air

entering

indoor

coil ºF

INDOOR

COIL

DRY BULBDRY

BULB

WET

BULB

B

T

Drop

19º

A

Dry−bulb

Wet−bulb ºF

A

72º

B

64º

C

53º

air flowair flow

All temperatures are

expressed in ºF

Figure 4. Checking Indoor Airflow over Evaporator Coil using Delta−T (DT) Chart

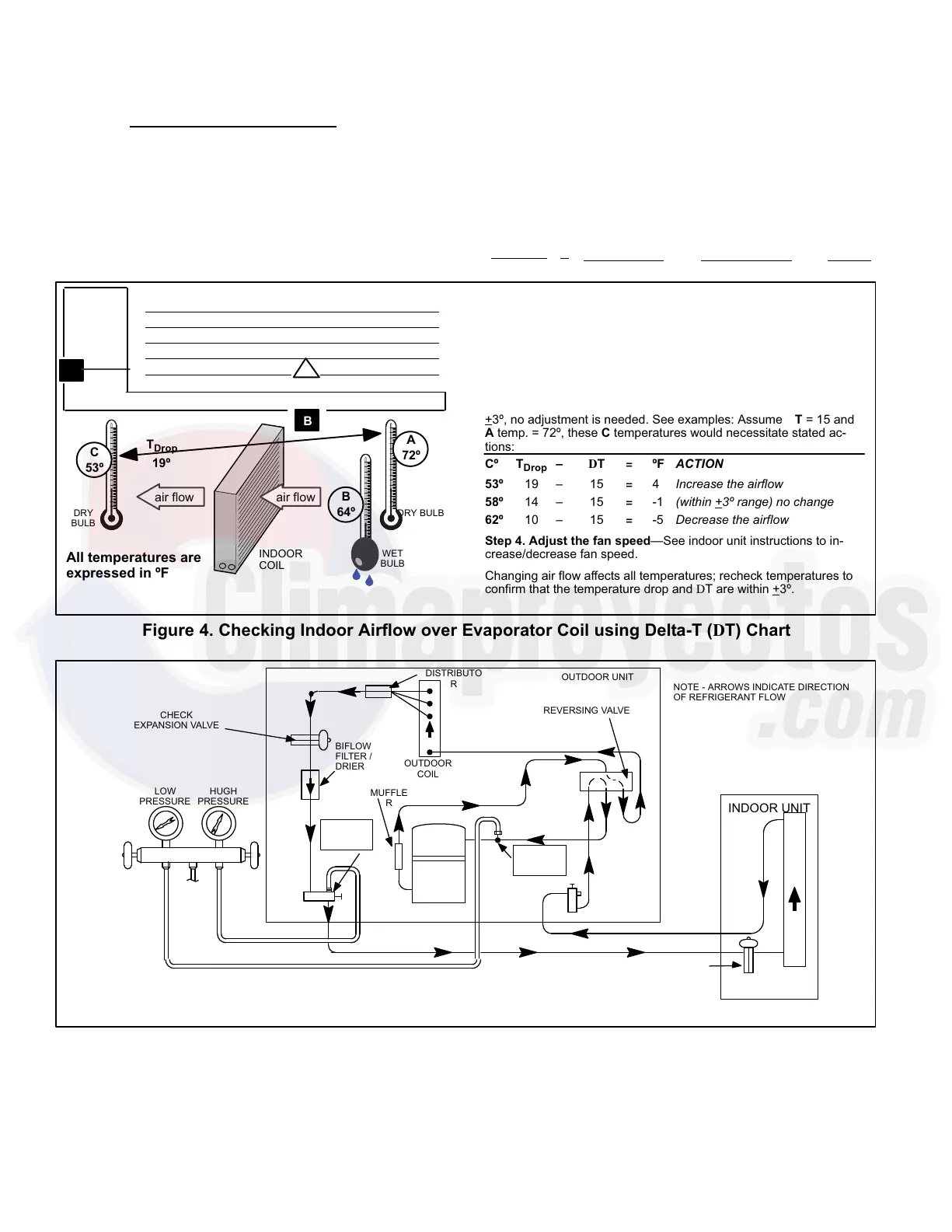

NOTE − USE GAUGE PORTS ON VAPOR LINE VALVE AND LIQUID VALVE FOR EVACUATING REFRIGERANT

LINES AND INDOOR COIL. USE VAPOR GAUGE PORT TO MEASURE VAPOR PRESSURE DURING

CHARGING.

OUTDOOR

COIL

CHECK

EXPANSION VALVE

BIFLOW

FILTER /

DRIER

TO

HFC−410

A DRUM

LOW

PRESSURE

COMPRESSO

R

REVERSING VALVE

VAPOR

LINE

VALVE

MUFFLE

R

NOTE − ARROWS INDICATE DIRECTION

OF REFRIGERANT FLOW

CHECK EXPANSION VALVE

INDOOR UNIT

OUTDOOR UNIT

LIQUID

SERVICE

PORT

GAUGE

MANIFOLD

DISTRIBUTO

R

INDOOR

COIL

VAPOR

SERVICE

PORT

HUGH

PRESSURE

LIQUID

LINE

VALVE

Figure 5. 13HPX Cooling Cycle (Showing Gauge Manifold Connections)

Loading...

Loading...