Page 27

The controller uses sensing devices to sense what posi-

tion the rotor is in at any given time. By sensing the posi-

tion of the rotor and then switching the motor windings on

and o in sequence, the rotor shaft turns the blower.

Operation

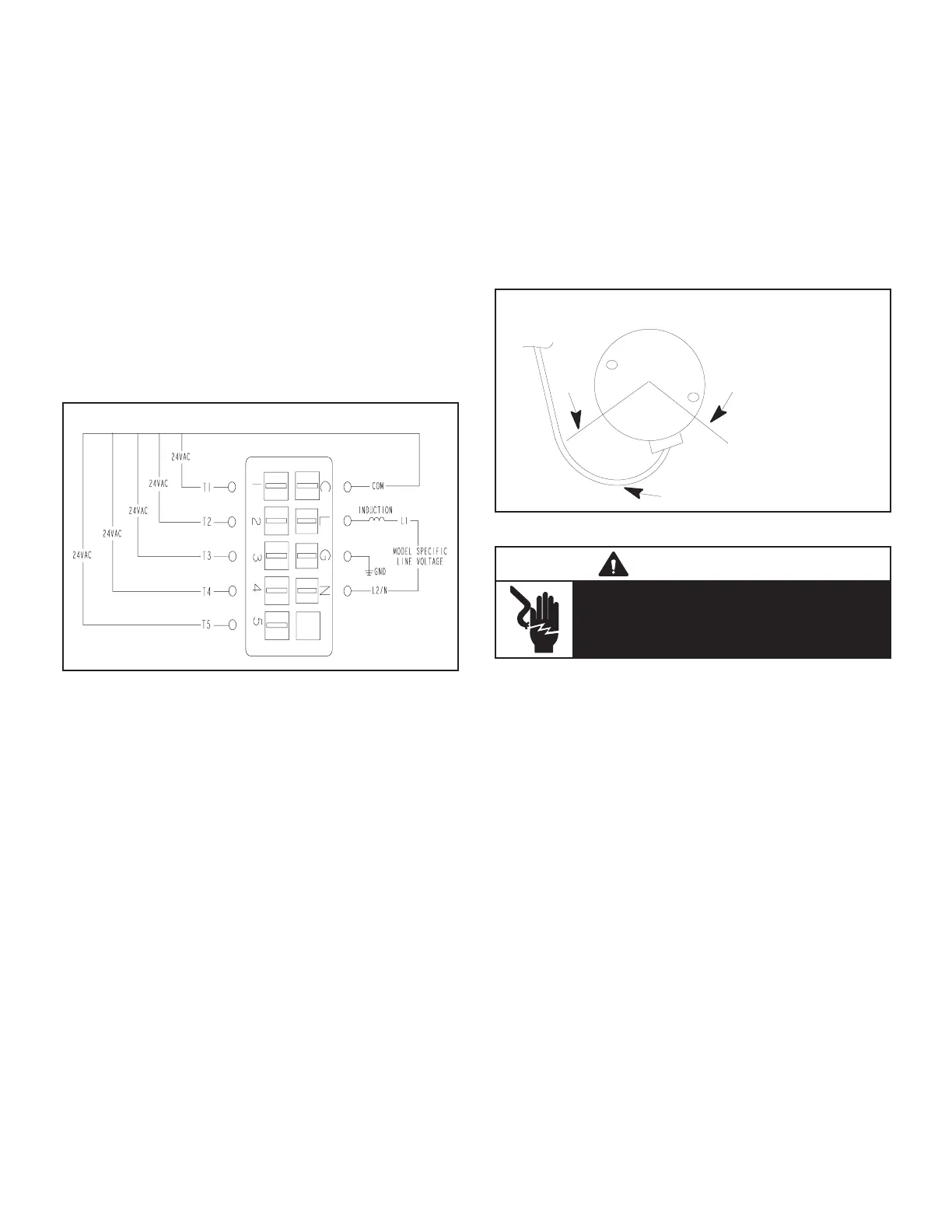

The 230VAC voltage connections to the motor are labeled

L, G and N.

• 230VAC L = L1 115VAC, G = Ground, N = L2 115VAC

The 230VAC is connected to the motor at all times. This

voltage operates the internal electronics and drives the

motor. In addition, the motor requires a low voltage to op-

erate. The low voltage to the motor is delivered to taps

1-5 and the (C) terminal from the control relay. The mo-

tor accepts a communication signal of 24VAC on these

taps. Instead of energizing a motor speed (winding) on a

PSC motor for each demand (heat cool, constant fan); the

communication voltage directs the motor to operate at the

torque value stored for each tap.

VOLTAGE CONNECTIONS

FIGURE 24

During each demand, the fan motor will maintain the se-

lected torque during changes in the systems external stat-

ic pressure (ESP) (constant torque). If ESP increases the

motor will use more power (current) to maintain torque.

The motor has a programmed limit of operation to protect

itself from damage, due to the energy it must use to main-

tain torque at high external static pressures. If the systems

maximum total ESP is exceeded, torque will not be main-

tained, however the motor will deliver as much torque as

possible, without causing damage to itself.

Constant torque allows the fan motor to maintain the torque

(current) delivered to the motor when ESP is higher than

recommended and/or changes during system operation.

ESP (the resistance to the movement of air) is increased

when duct work is undersized, poorly constructed and/or

full or dirt or debris. ESP can increase during system op-

eration when dirt builds up on the air distribution systems

components, especially the lter, and when customers

close or block grilles and registers. When torque is main-

tained, airow does not decrease as fast as it would on a

PSC motor system. This decreases the eect ESP has on

loss of airow, providing better system performance and

eciency within the limits of the motor design.

The fan motor has no programmable (On) delays but mul-

tiple (O) delays are programmed into the motor. The o

delay is programmed into the motor and can not be ad-

justed.

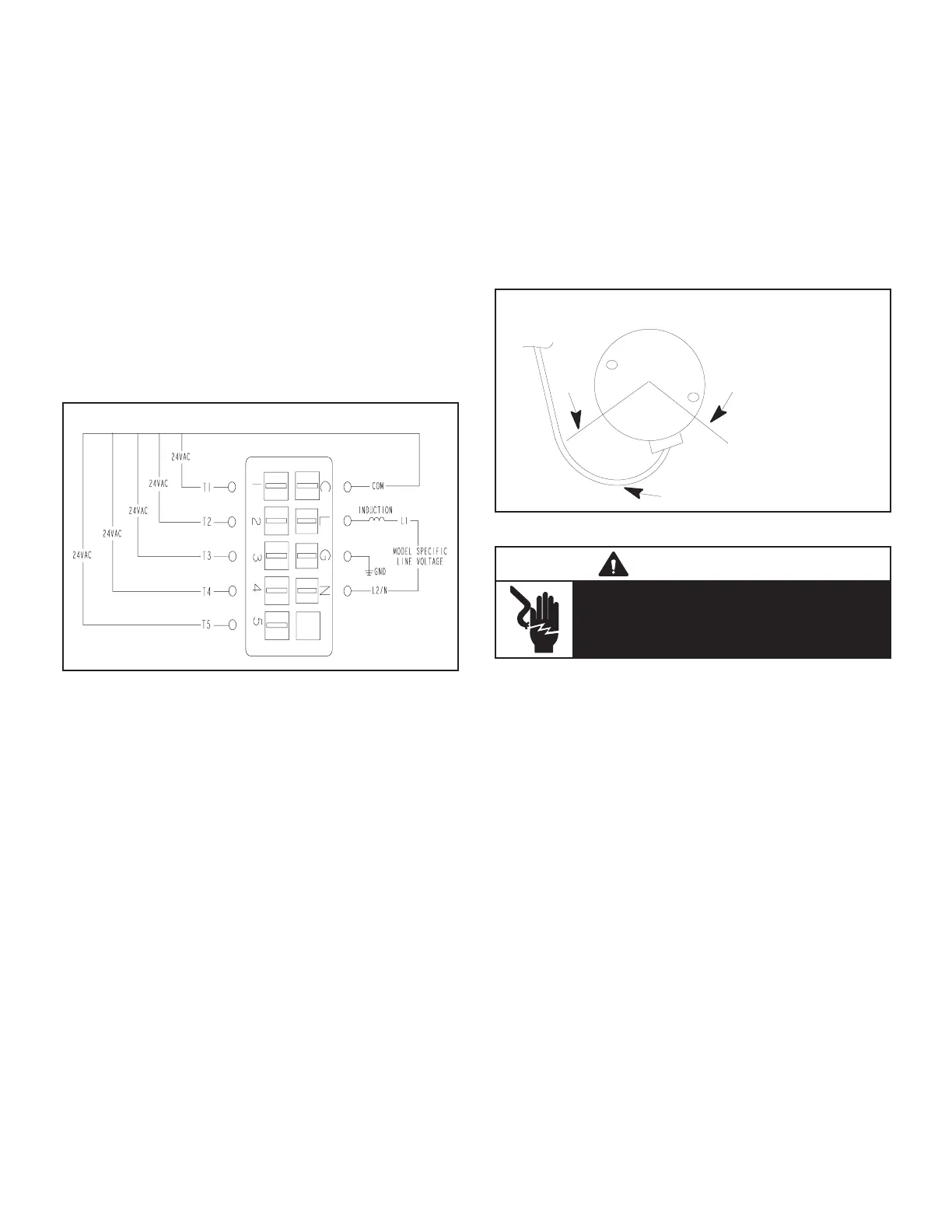

Installation

It is recommended that the electrical connections on the

ECM be facing down or between the 4 and 8 O-clock po-

sition, and a drip loop formed out of the wiring harness

leaving the motor. This is to prevent any moisture or water

that may get into the motor area from running into the con-

nectors where it could cause damage to the control. See

gure 25.

DRIP LOOP

BACK OF

UNIT

CONNECTOR

ORIENTATION (BETWEEN

4 AND 8 O'CLOCK)

DRIP LOOP

FIGURE 25

WARNING

Disconnect power from unit and wait at least

ve minutes to allow capacitors to discharge

before attempting to service motor. Failure to

wait may cause personal injury or death.

INDOOR BLOWER MOTOR (B3) CONTROL TROUBLE-

SHOOTING

Before troubleshooting any HVAC system, it is a good

practice to become familiar with the components and wir-

ing diagram. On fan motor systems it is a good practice to

check the tap selections and delay settings.

If the motor is running but the system is noisy, shutting

down on its limits or safeties or the evaporator coil is freez-

ing, there is a good chance the motor is good. The prob-

lem is most likely external to the motor.

• Check the tap selections using the HVAC OEM guide.

• Check the air distribution system components for dirt

load and closed dampers, registers and grilles.

• Measure the total external static pressure. Make repair(s)

if above the recommended maximum level and conrm

airow at the new total ESP with the air ow tables (be-

ginning on page 6). Aftermarket lter sizing is a com-

mon issue.

Loading...

Loading...