Page 17

10 - Flip access door and replace it on the unit.

11 - Set unit so that it is sloped toward the drain pan end

of the unit. See sloping section gure 17. Connect

return and supply air plenums as required using

sheet metal screws.

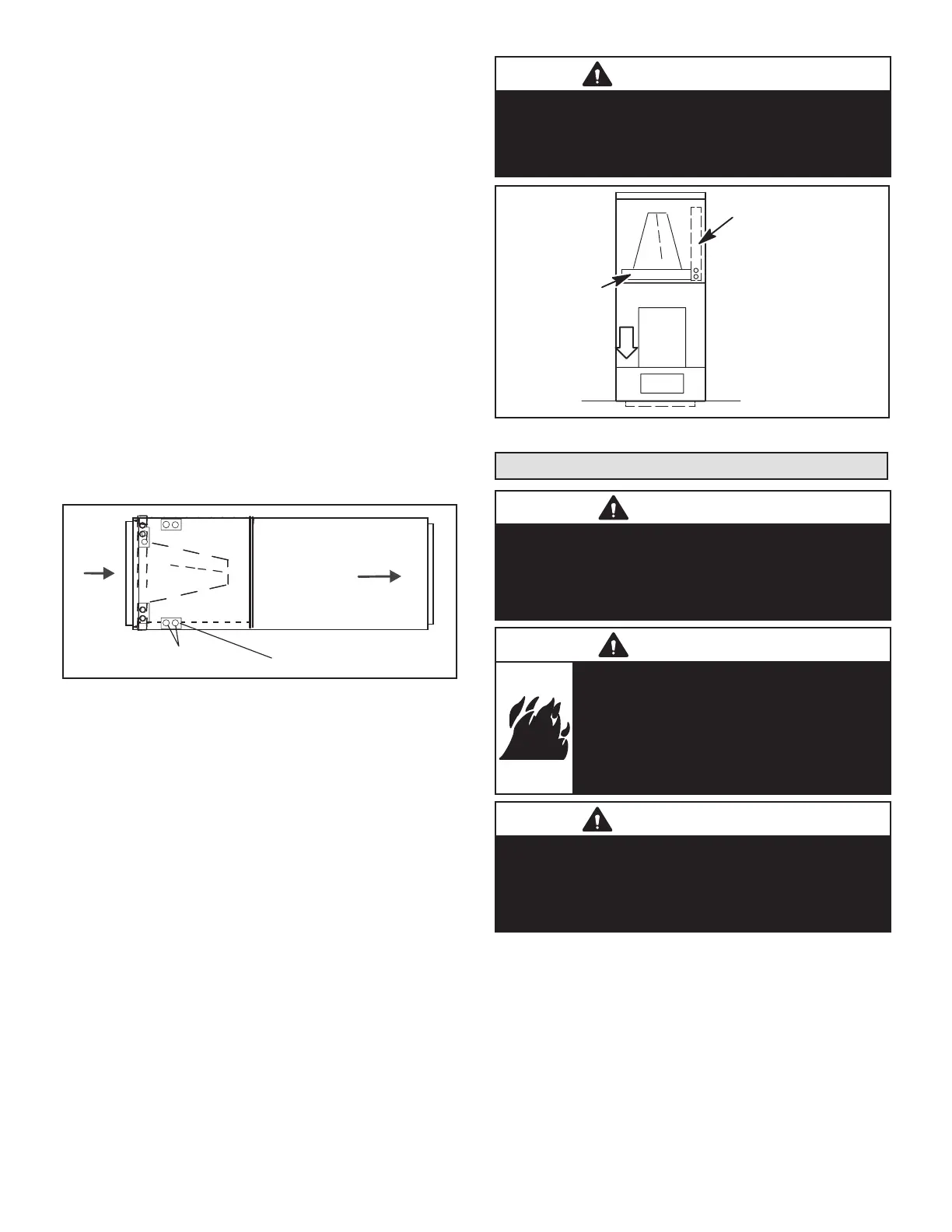

12 - If suspending the unit, it must be supported along the

entire length of the cabinet. If using chain or strap,

use a piece of angle iron or sheet metal attached to

the unit (either above or below) so that the full length

of the cabinet is supported. Use securing screws no

longer than 1/2ʺ to avoid damage to coil or lter, as

illustrated in gure 12. Connect return and supply

air plenums as required using sheet metal screws.

RIGHT-HAND DISCHARGE

1 - Determine which plugs are required for drain line

connections.

2 - With access door removed, remove drain line plugs

to install drain lines.

3 - Set unit so that it is sloped toward the upow drain

pan end of the unit and level from front to back of

unit (see gure 15).

4 - The horizontal conguration is shown in gure 15.

Drains

AIR FLOW

PLUGS

RIGHT‐HAND DRAINS

FIGURE 15. Right-Hand Discharge Conguration

5 - If the unit is suspended, the entire length of the

cabinet must be supported. If you use a chain or

strap, use a piece of angle iron or sheet metal

attached to the unit (either above or below) to

support the length of the cabinet. Use securing

screws no longer than 1/2 inch to avoid damaging

the coil or lter. See gure 12. Use sheet metal

screws to connect the return and supply air plenums

as required.

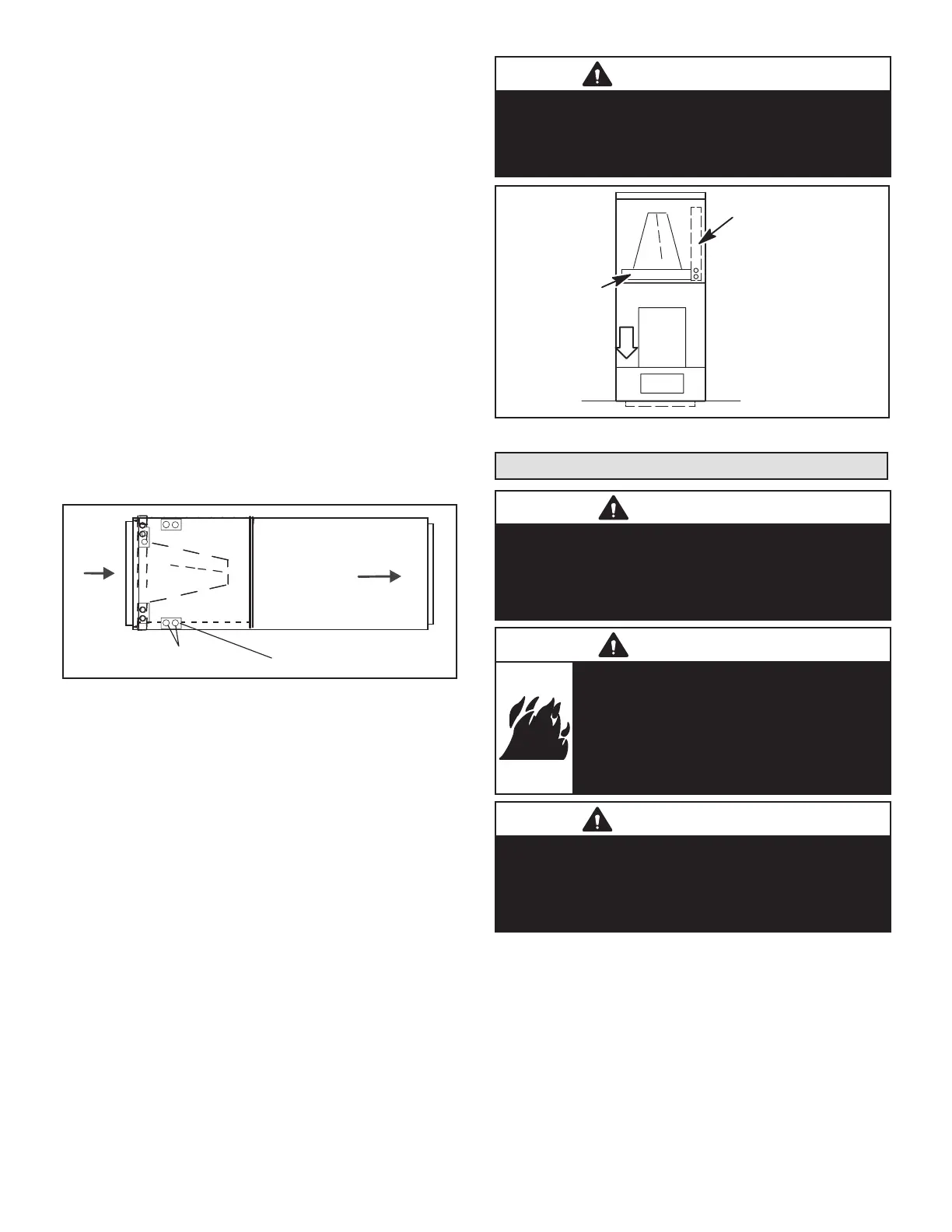

DOWNFLOW APPLICATION

NOTE – If downow application is required, separately or-

der kit number Y9658 (-024 through -030) or Y9659 (-036

through -042) .Use the installation instruction 507797-01

provided with the downow kit. Also use metal or class I

supply and return air plenums. Figure 16 shows proper

orientation.

IMPORTANT

If electric heat section with circuit breakers (ECBA25) is

installed in a CBA25UHE unit in a downow application,

the circuit breakers must be rotated 180° to the UP

position. See ECBA25 installation instructions for more

details.

HORIZONTA L DRAIN PAN

(REMOVE FROM UNIT)

UPFLOW /

DOWNFLOW

DRAIN PAN

FIGURE 16. Downow Discharge Position

Brazing Connections

WARNING

Polyol ester (POE) oils used with HFC-410A refrigerant

absorb moisture very quickly. It is very important that the

refrigerant system be kept closed as much as possible.

DO NOT remove line set caps or service valve stub caps

until you are ready to make connections.

WARNING

Danger of re. Bleeding the refrigerant

charge from only the high side may result

in pressurization of the low side shell and

suction tubing. Application of a brazing torch

to a pressurized system may result in ignition

of the refrigerant and oil mixture. Check the

high and low pressures before applying heat.

IMPORTANT

To prevent the build-up of high levels of nitrogen when

purging, it must be done in a well-ventilated area. Purge

low-pressure nitrogen (1 to 2 psig) through the refrigerant

piping during brazing. This will help to prevent oxidation

and the introduction of moisture into the system.

Loading...

Loading...