Page 26

Sequence of Operation

Cooling (Cooling Only or Heat Pump)

On all models, the 24 volt line will go directly to the termi-

nal board from the transformer. The normally open con-

tacts close, causing the indoor blower motor to operate;

depending on the indoor blower motor, there may be a

delay. The circuit between R and Y is completed, closing

the circuit to the contactor in the outdoor unit, starting the

compressor and outdoor fan motor.

On heat pumps, circuit R and O energizes the reversing

valve, switching the valve to the cooling position. (The re-

versing valve remains energized as long as the thermo-

stat selector switch is in the COOL position.)

At the completion of the cooling demand, the indoor blow-

er and outdoor unit should cycle o. Air handler should

cycle o 45 seconds after the outdoor unit shuts o.

Heating (Electric Heat Only)

When the thermostat calls for heat, the circuit between R

and W is completed, and the heat sequencer is energized.

A time delay follows before the heating elements and the

indoor blower motor come on. Units with a second heat

sequencer can be connected with the rst sequencer to W

on the thermostat sub-base, or they may also be connect-

ed to a second stage on the sub-base.

Heating (Heat Pump)

On all models, the 24 volt line will go directly to the termi-

nal board from the transformer. The normally open con-

tacts close, causing the indoor blower motor to operate;

depending on the indoor blower motor, there may be a

delay. The circuit between R and Y is completed, closing

the circuit to the contactor in the outdoor unit, starting the

compressor and outdoor fan motor.

If the room temperature continues to decrease, the cir-

cuit between R and W1 is completed by the second-stage

heat room thermostat. Circuit R-W1 energizes a heat se-

quencer. The completed circuit will energize supplemen-

tal electric heat (if applicable). Units with a second heat

sequencer can be connected with the rst sequencer to

W1 on the thermostat. They may also be connected to

a second heating stage W2 on the thermostat sub-base.

Emergency Heat (Heating Heat Pump)

If the selector switch on the thermostat is set to the emer-

gency heat position, the heat pump will be locked out of

the heating circuit, and all heating will be electric heat (if

applicable). A jumper should be placed between W2 and E

on the thermostat sub-base so that the electric heat con-

trol will transfer to the rst-stage heat on the thermostat.

This will allow the indoor blower to cycle on and o with

the electric heat when the fan switch is in the AUTO po-

sition.

Constant Torque Speed Blower Motor

(ECM) (B3)

Blower Motor (B3)

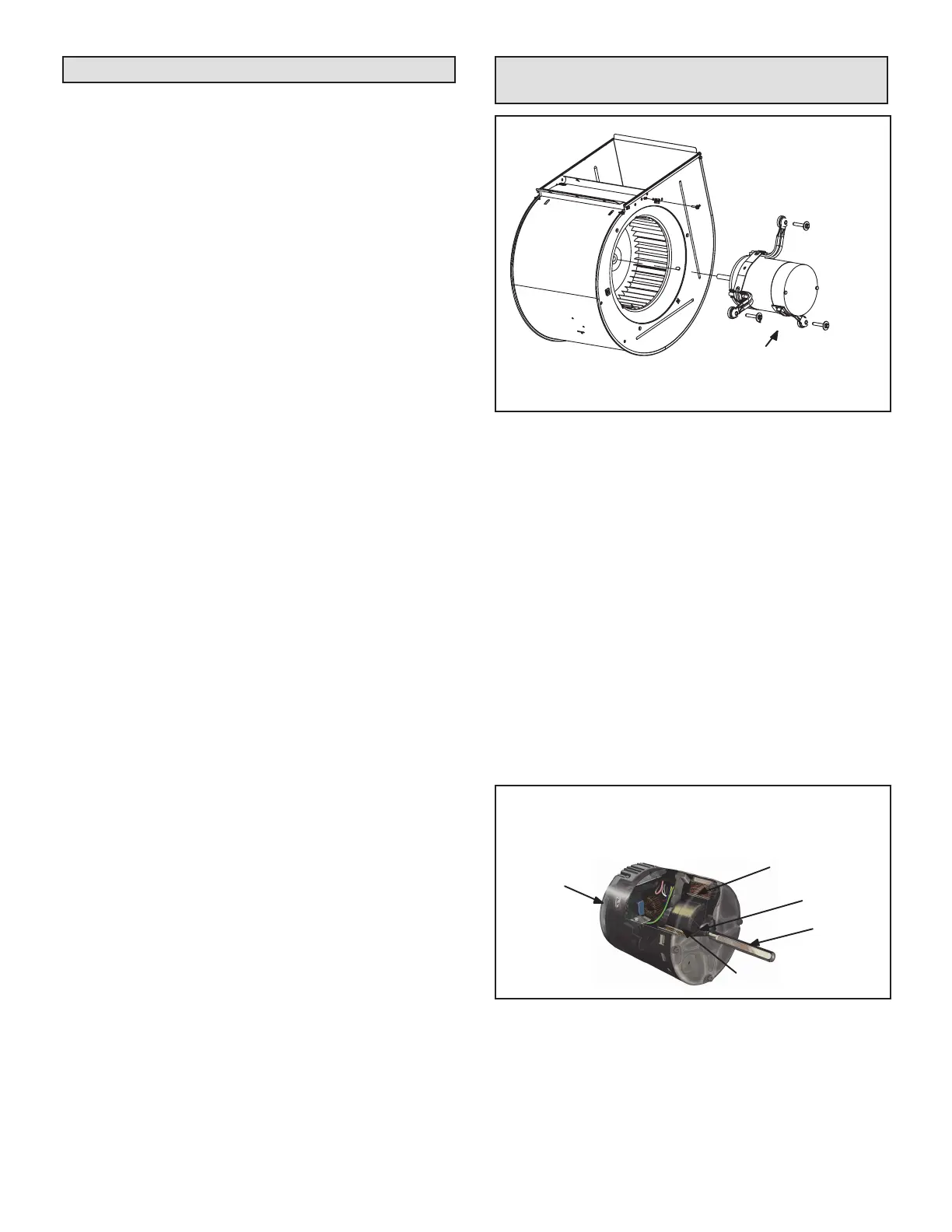

To Remove Blower From Unit: Remove wiring jack plug and

three screws and slide blower out.

TYPICAL BLOWER MOTOR

(B3) REMOVAL

FIGURE 22

The constant torque ECM (electronically commutated mo-

tor) communicates with the air handler control via 24VAC

inputs. It is programmed to provide a constant level of

torque (current / power) to the motor. This is a multi-tap

motor with the ability to have 1 to 5 programmed levels of

torque (see table 4). Each value equals a specic amount

of torque to create the proper amount of airow for each

system demand. This value is specic to model and size

of system.

Each tap can have a unique amount of torque programmed

for a specic purpose. For example, switching from Tap 1

to Tap 2 may increase the airow, but not necessarily at

a specic interval like changing from low to medium low

speed on a PSC motor.

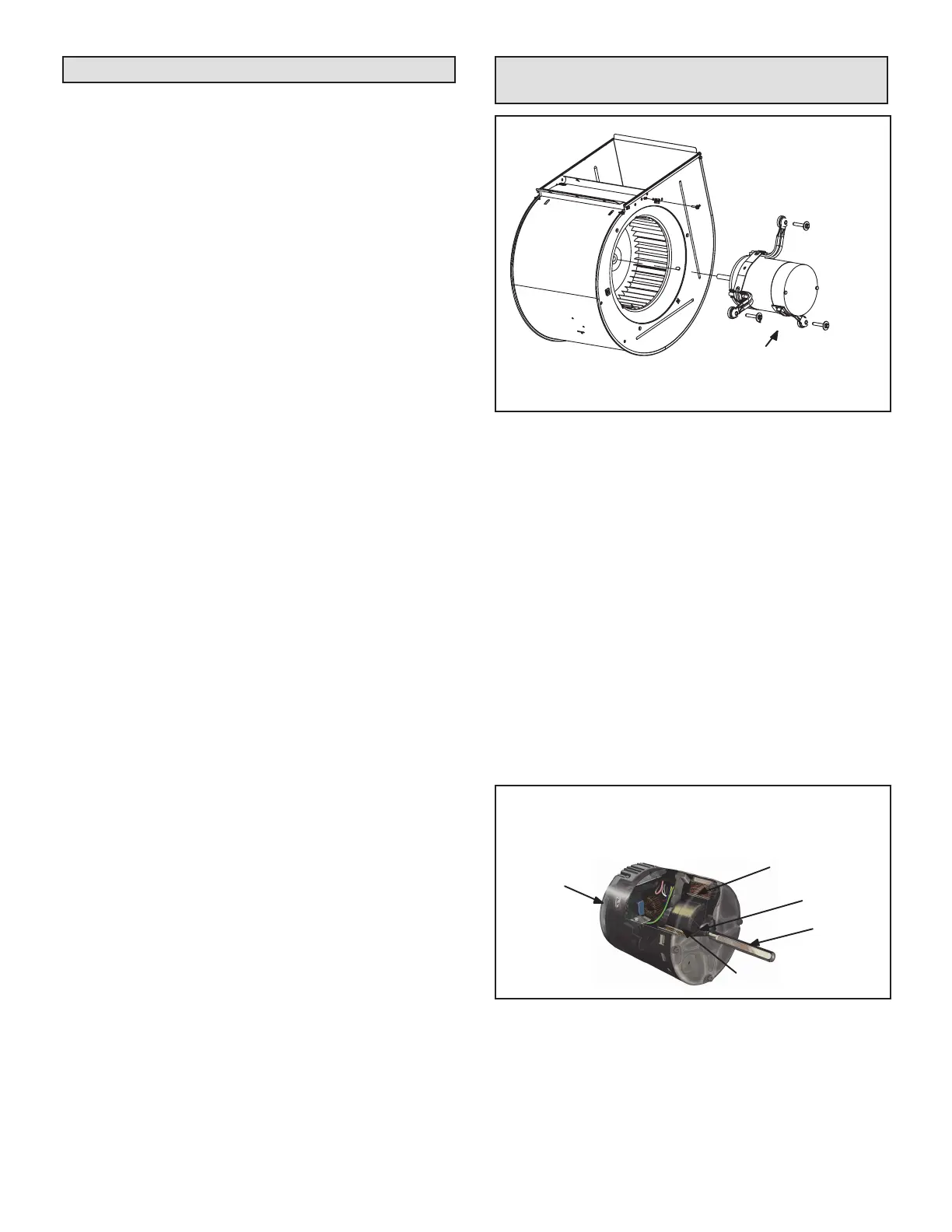

Internal components are shown in gure 23. The stator

windings are split into three poles which are electrically

connected to the controller. This arrangement allows mo-

tor windings to turn on and o in sequence by the control-

ler.

STATOR

(WINDINGS)

OUTPUT

SHAFT

BEARING

ROTOR

CONTROLLER

BLOWER MOTOR COMPONENTS

FIGURE 23

Loading...

Loading...