FLEXYII_WSHP-IOM-1307-E - 67 -

GAS BURNER TROUBLESHOUTING

If faults reported on CLIMATIC

-Reset the CLIMATIC.

-Check voltage: 230V after circuit breaker.

-Check GAS isolation shut-off valves are open.

-Check GAS pressure at the inlet of the GAS valves. It must be >20 mbar when the Burners shut down.

-Adjust the set points to priorities the burner. Increase the value of the room temperature set point to a temperature higher than

actual room temperature.

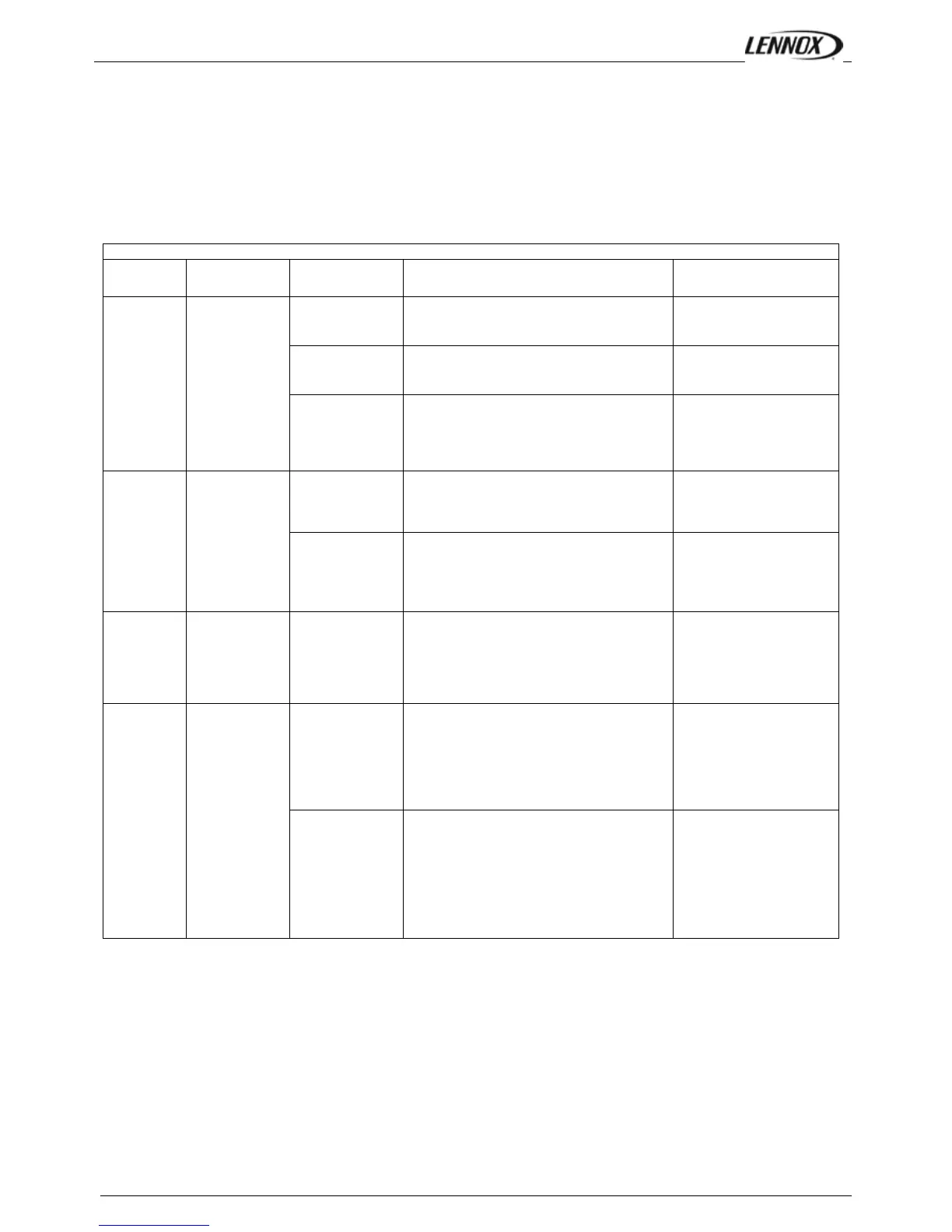

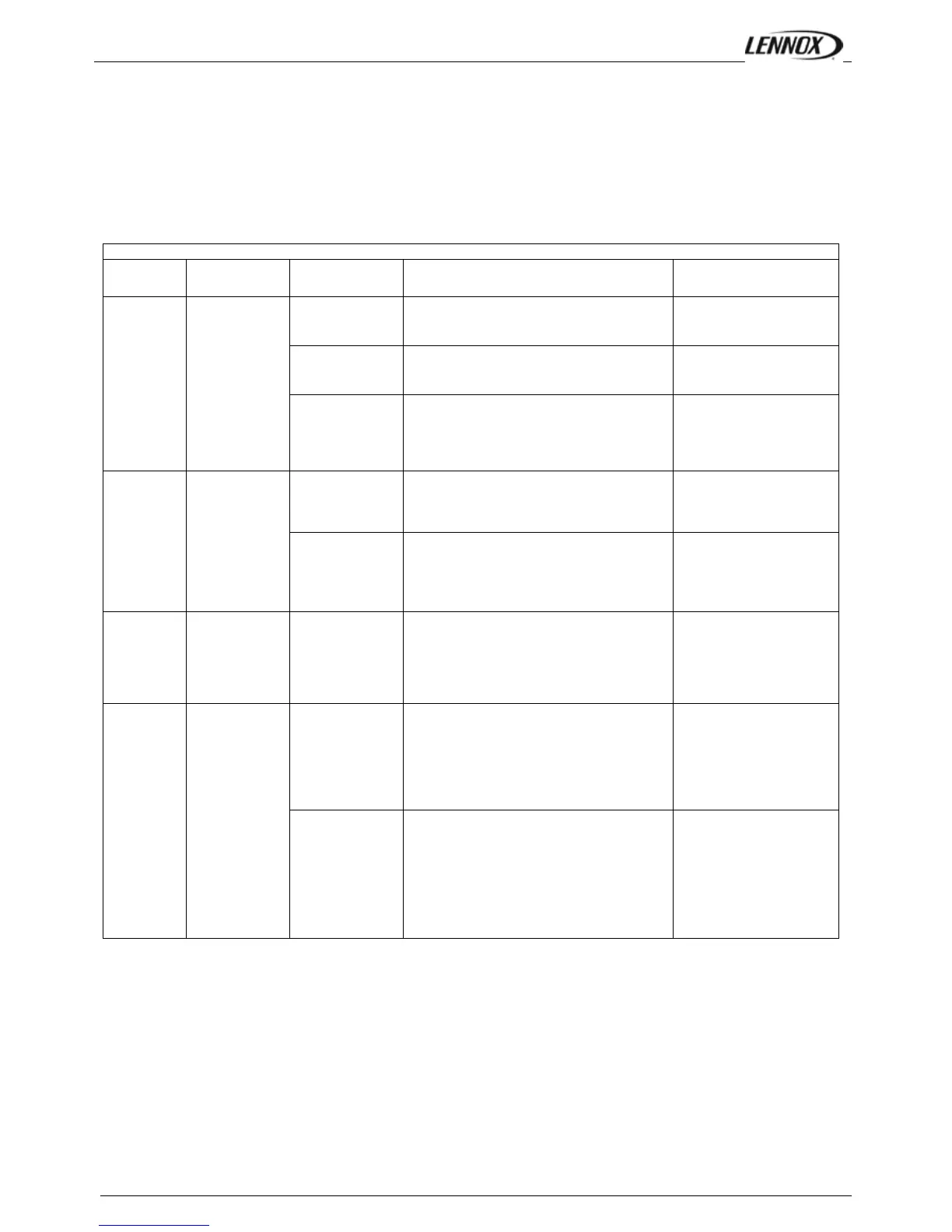

DIAGNOSTIC TABLE BALTIC GAS BURNER

STAGE

NORMAL

OPERATION

POSSIBLE

FAULT

ACTION POSSIBLE SOLUTION

Heating

Requested

Extraction fans

start

+ Check connections on the blower

thermostat.

+ Replace thermostat

Lack of gas

supply

+ Check valve’s opening & supply pressure + Restore gas supply

superheat

thermostat on the

gas burner

+ Check superheat thermostat’s operation

after manual reset

+ Replace superheat

thermostat

Starting of

the

extraction

fans

Extraction Fans

are running

safety shutdown

by the ignition

+ Check connections of the control block on

the gas valve

+ Repositioning of the

control block on the valve

+ Replace valve

Nothing happens

+ Check the free movement of the fan wheel

+ Check Electrical connection on the Gas

Ignition Control Block and on EF connection

Board

+ Check the Fan supply voltage

+ Replace fan

+ Replace EF connection

board If necessary

Extraction

Fan is ON

seconds: pre-

ventilation the

fire-up

electrode

Continuous

Ventilation

without sparks

from fire-up

electrode

+ Check the fire-up electrode

+ Check the pressure drop at the pressure

switch: It must be higher than 165 Pa

+Check the good operation of the pressure

switch using an Ohmmeter and by artificially

creating a depression in the tube.

switch tube.

+ Change the pressure

switch.

Continuous

ventilation

and sparks

from fire up

electrode.

After a few

seconds the

gas burner

fires-up

the GAS Burner

still not operating

and safety

shutdown by the

Ignition Control

+ Check injection pressure during start-up

(Value for High Heat)

+Remove the control box from the gas

block.

+ Remove the air from the

Gas pipe-work

+ Adjust the injection

pressure to high heat

value.

+ Change the Control Box

Within 4 seconds

the gas Burner

fires-up BUT

safety shutdown

from the Ignition

Control Block.

+ Check the Position and connection of the

Ionisation Probe. It must not be Earthed

(230V).

+ Measure the Ionisation Current: It must be

higher than 1.5 microAmps.

+ Check the Type of GAS.

+Check the whole

electrical supply.

+ Adjust the supply and

injection pressure if gas is

different from natural gas

G20 :( G25 Gas of

Groningue for example).

Loading...

Loading...