Page 52

Manifold Pressure Measurement (FIGURE 52)

To correctly measure manifold pressure, the dierential

pressure between the positive gas manifold and the neg-

ative burner box must be considered. Use pressure test

adapter kit (available as Lennox part 10L34) to assist in

measurement.

1 - Remove the threaded plug from the outlet side of

the gas valve and install a eld-provided barbed

tting. Connect measuring device “+” connection to

barbed tting to measure manifold pressure.

2 - Tee into the gas valve regulator vent hose and

connect measuring device “-” connection.

3 - Start unit on low heat (35% rate) and allow 5 minutes

for unit to reach steady state.

4 - While waiting for the unit to stabilize, notice the

ame. Flame should be stable and should not lift

from burner. Natural gas should burn blue.

5 - After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

TABLE 32.

6 - Repeat steps 3, 4 and 5 on high heat.

7 - Shut unit o and remove manometer as soon as

an accurate reading has been obtained. Take care

to remove barbed tting and replace threaded plug.

8 - Start unit and perform leak check. Seal leaks if

found.

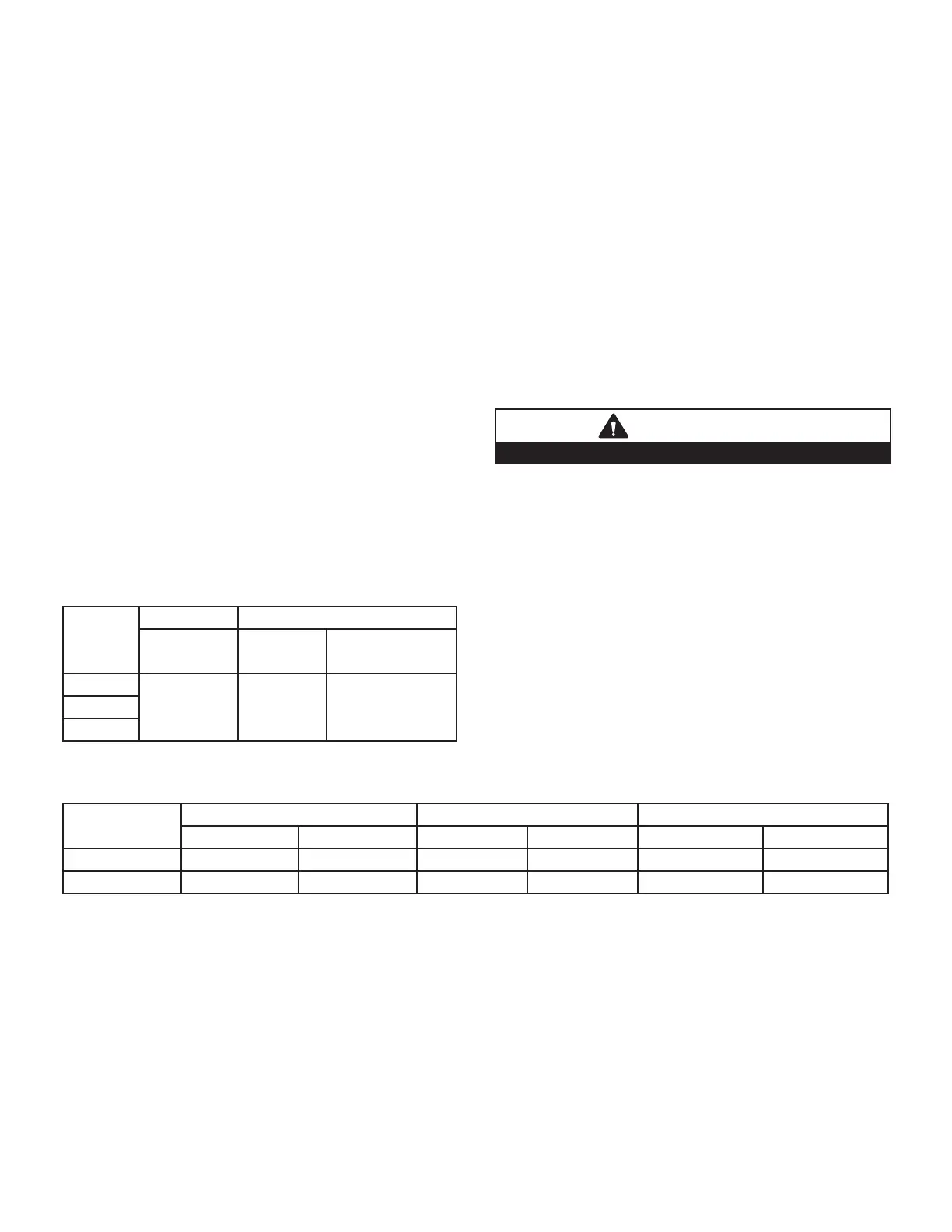

TABLE 31

Conversion Kit Requirements

Model

Input Size

LP/Propane High Altitude Pressure Switch

0 - 10,000 ft

(0 - 3048m)

0 - 7500 ft

(0 - 2286m)

7501 ft - 10,000 ft

(287 - 3048m)

070

65W77

Not

Required

14T67090

110

Operating Pressure Signal (Delta P) Measurement

(FIGURE 53)

Operating pressure signal can be taken while the manifold

pressure pressure check is taken (using two measuring

devices). Or, taken after the manifold pressure measure-

ment is complete.

1 - Tee into the negative line between the gas valve and

pressure switch and connect to measuring device

negative “-”.

2 - Tee into the positive line between the gas valve and

pressure switch and connect to measuring device

positive “+”.

3 - Start unit on low heat (35% rate) and allow 5 minutes

for unit to reach steady state.

4 - After allowing unit to stabilize for 5 minutes, record

operating pressure signal and compare to value

given in TABLE 32.

5 - Repeat steps 3 on 4 high heat.

WARNING

Do not attempt to make adjustments to the gas valve.

.

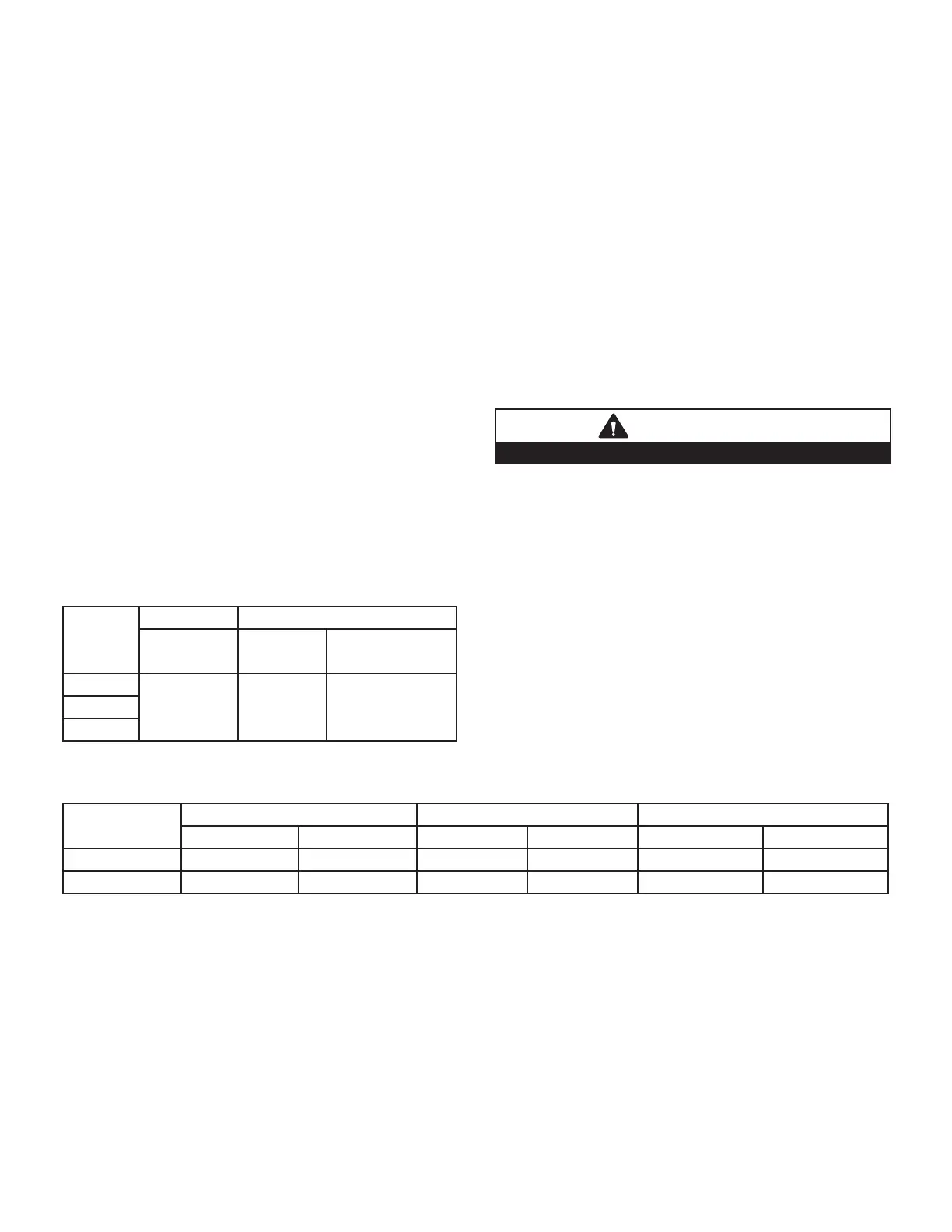

TABLE 32

Manifold and Operating Signal Pressures in inches 0 - 7500 ft (0 - 2286 m)

SLP99 Firing

Rate

Manifold Pressure Natural Gas Manifold Pressure LP/Propane Operating Pressure Signal (Delta P)

Min Max Min Max Min Max

Low 0.4 0.95 1.2 2.8 0.20 0.40

High 3.0 3.8 9.1 10.5 0.95 1.25

NOTE - A natural to LP/propane gas changeover kit is necessary to convert this unit. Refer to the changeover kit instal-

lation instruction for the conversion procedure.

NOTE - The values given in table are measurements only. The gas valve should NOT be adjusted.

Loading...

Loading...