4.

Measure the air gap s

L

between stator (1) and armature plate (2) in the vicinity of the cap

screws (3) using a surface feeler gauge.

NOTICE

▶

With the holding brake HBR and applicaon brake ABR (motor protecon class IP65/66) the

air gap cannot be adjusted! If the air gap s

L,max

is reached, the brakes must be replaced.

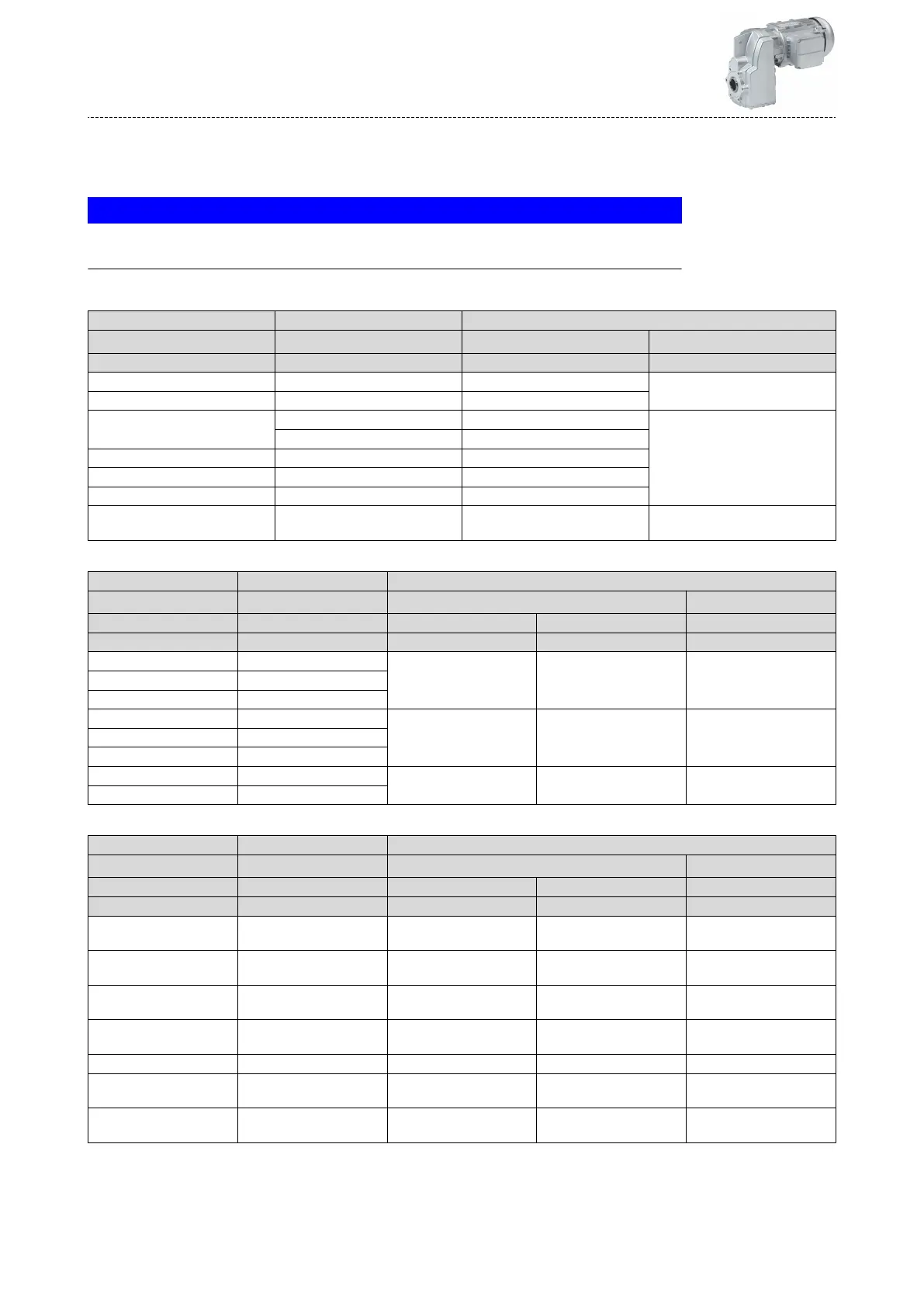

Holding brake HBR

Brake Braking torque is stac Air gap

s

L,max

s

L,N

Nm mm mm

HBR 06 4 0.6

0.2 ±0.1

HBR 08 8 0.6

HBR 10

16 0.7

0.3 ±0.1

23 0.5

HBR 12 32 0.8

HBR 14 60 0.8

HBR 16 80 0.9

HBR 18 150 0.6 0.4

+0.10

-0.05

Applicaon brake ABR, protecon class IP54/55

Brake Tightening torque Air gap

s

L,max

s

L,N

Service brake Holding brake

Nm mm mm

ABR 06 3.0

0.50 0.30 0.2

+0.10

-0.05

ABR 08 5.9

ABR 10 10.1

ABR 12 10.1

0.75 0.45 0.3

+0.10

-0.05

ABR 14 24.6

ABR 16 24.6

ABR 18 24.6

1.00 0.60 0.4

+0.10

-0.05

ABR 20 48.0

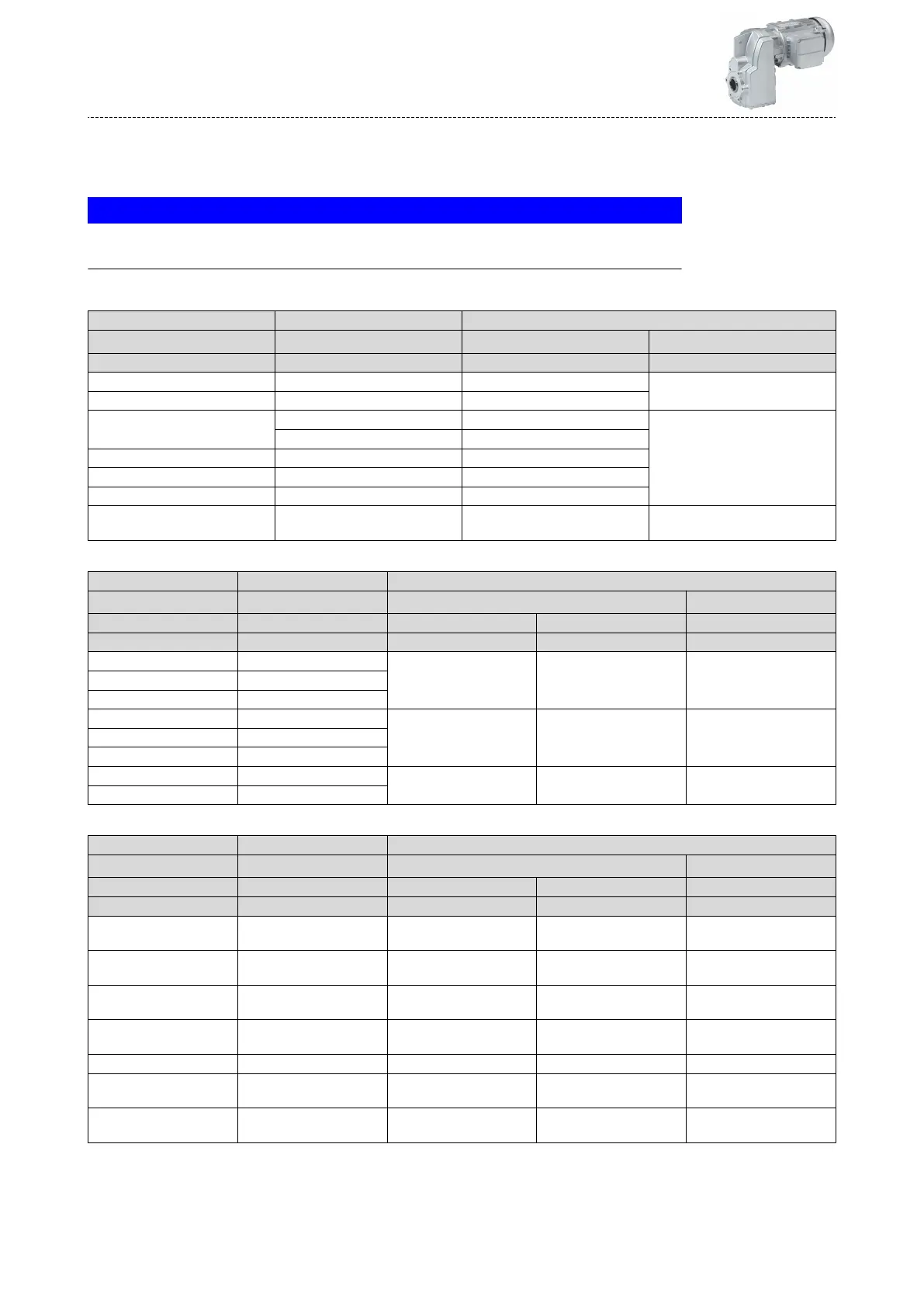

Applicaon brake ABR, protecon class IP65/66

Brake Tightening torque Air gap

s

L,max

s

L,N

Service brake Holding brake

Nm mm mm

ABR 06 3.0 0.50 0.30 0.2

+0.08

-0.05

ABR 08 5.9 0.50 0.30 0.2

+0.08

-0.05

ABR 10 10.1 0.50 0.30 0.2

+0.13

-0.05

ABR 12 10.1 0.60 0.45 0.3

+0.08

-0.10

ABR 14 24.6 0.75 0.45 0.3 ±0.1

ABR 16 24.6 0.80 0.50 0.3

+0.15

-0.05

ABR 18 24.6 1.0 0.65 0.4

+0.20

-0.10

Maintenance

Maintenance work

60

Loading...

Loading...