58D6056 25

3" Minimum

STOVE INSTALLATION

A listed manual shutoff valve must be installed upstream of the appliance. Union tee and plugged

1

/8" NPT pressure tapping

point should be installed upstream of the appliance. See Figure 32.

IMPORTANT: Install main gas valve (equipment shutoff valve) in an accessible location. The main gas valve is

for turning on or shutting off the gas to the stove.

Check your building codes for any special requirements for

locating equipment shutoff valve to stoves.

Apply pipe joint sealant lightly to make threads. This will

prevent excess sealant from going into pipe. Excess sealant in

pipe could result in clogged burner system valves.

A manual shutoff valve must be installed

upstream of the appliance. Union tee

and plugged

1

/8" NPT pressure tapping

point should be installed upstream of

the appliance. See Figure 32.

CAUTION

Use pipe joint sealant that is resistant

to liquid petroleum (LP) gas.

CAUTION

We recommend that you install a sediment trap/drip leg in supply line as shown in Figure 32. Locate sediment trap/drip

leg where it is within reach for cleaning. Install in piping system between fuel supply and burner system. Locate sediment

trap/drip leg where trapped matter is not likely to freeze. A sediment trap traps moisture and contaminants. This keeps them

from going into the burner system gas controls. If sediment trap/drip leg is not installed or is installed wrong, burner system

may not run properly.

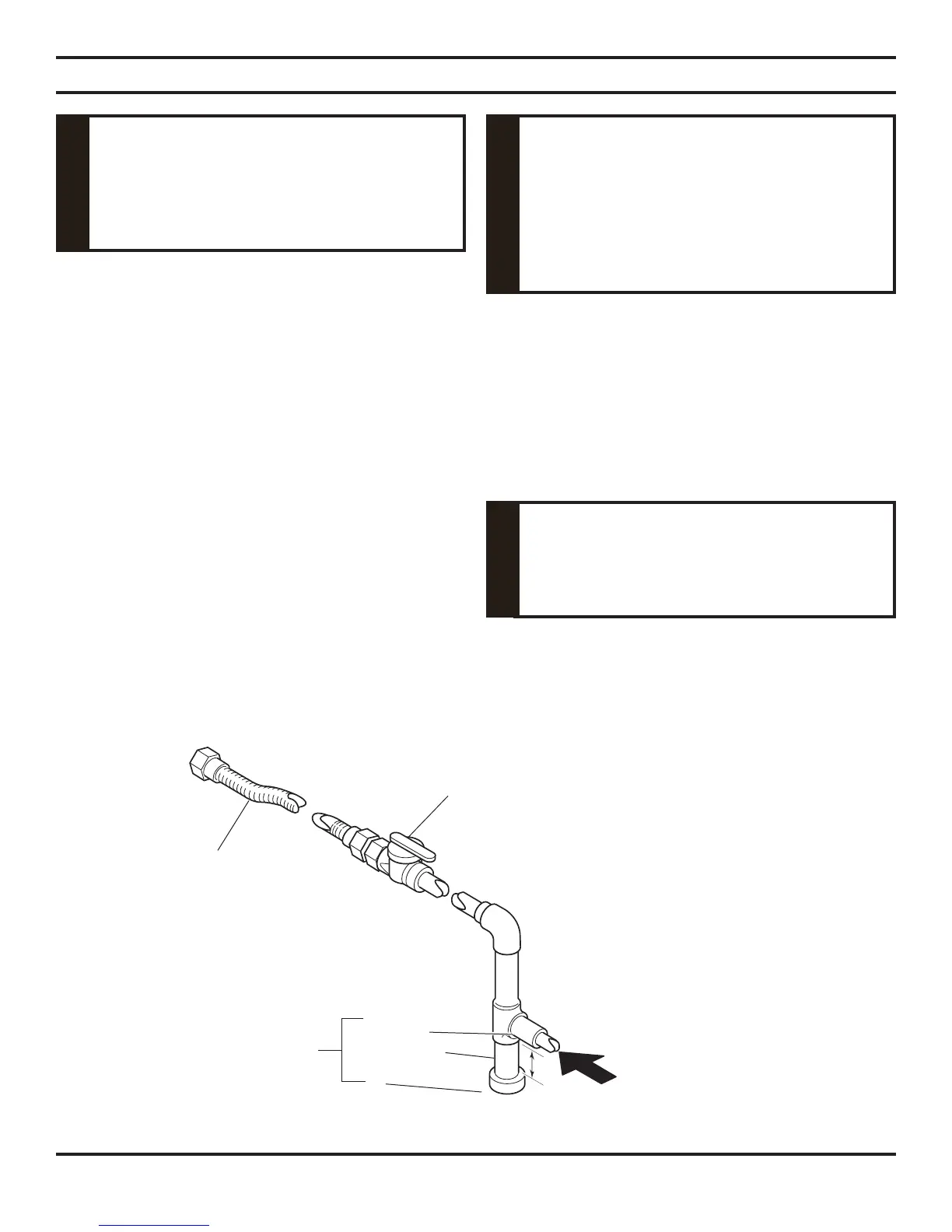

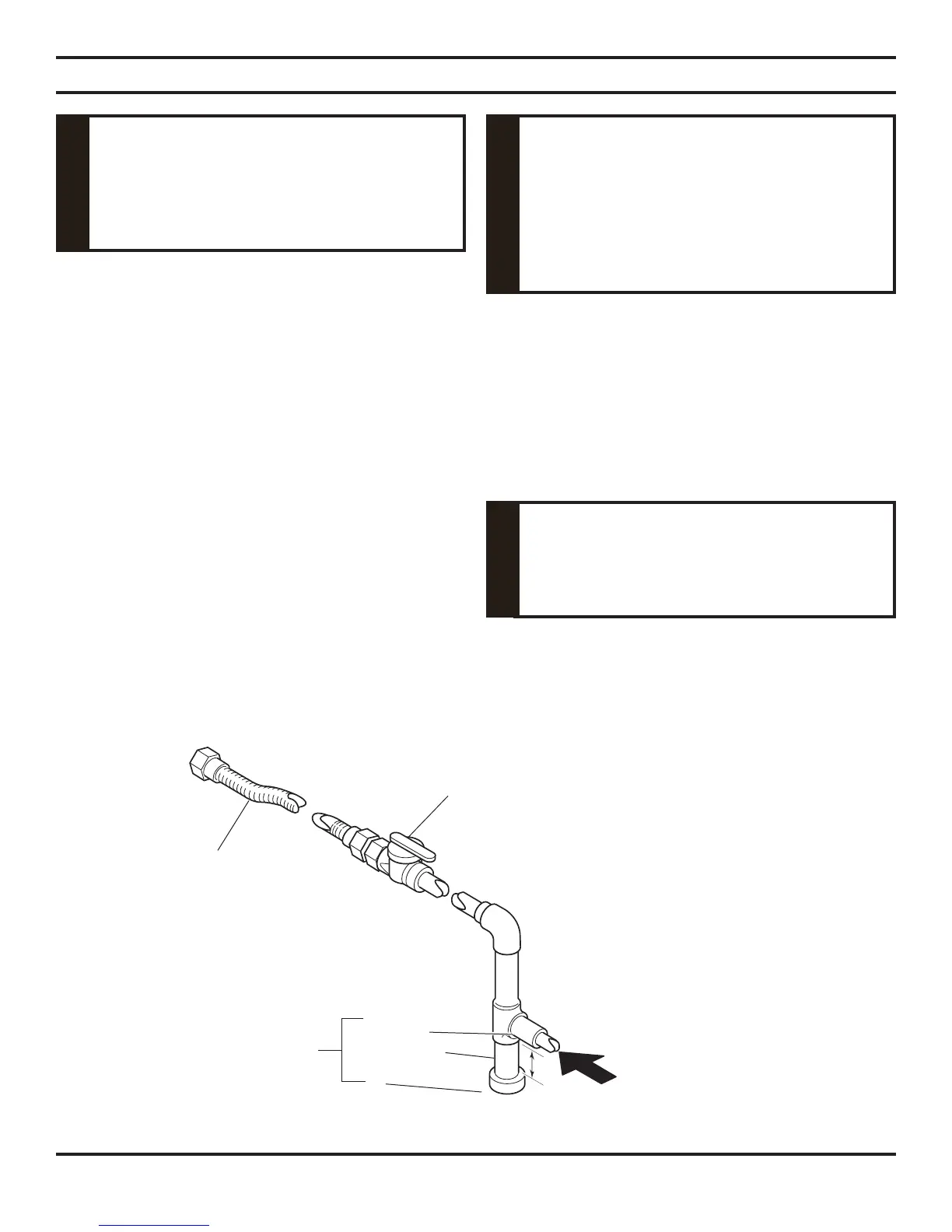

Figure 32 - Gas Connection

Tee Joint

Pipe Nipple

Cap

Approved Flexible

Gas Line

CSA Design-Certifi ed Equipment

Shutoff Valve with

1

/8" NPT Tap*

Sediment Trap/Drip Leg

Natural Gas

From Gas Meter

(5" W.C. to 10.5" W.C. Pressure)

Propane/LP

From External Regulator

(11" W.C. to 13" W.C. Pressure)

NOTE : The gas line connection may be made using

1

/2" rigid tubing or an approved fl ex connector. Since

some municipalities have additional local codes it is always best to consult your local authorities and

the current edition of the National Fuel Gas Code ANSI.Z223.1, NFPA54. In Canada CAN/CGA-B149 (1 or

2) Installation Code.

Only persons licensed to work with

gas piping may make the necessary

gas connections to this appliance.

WARNING

Loading...

Loading...