058 059

_

COMPREHENSIVE APPLICATION AND INSTALLATION MANUAL

LG Electronics

Installation check listConguration

System Design ApplicationsIntroduction

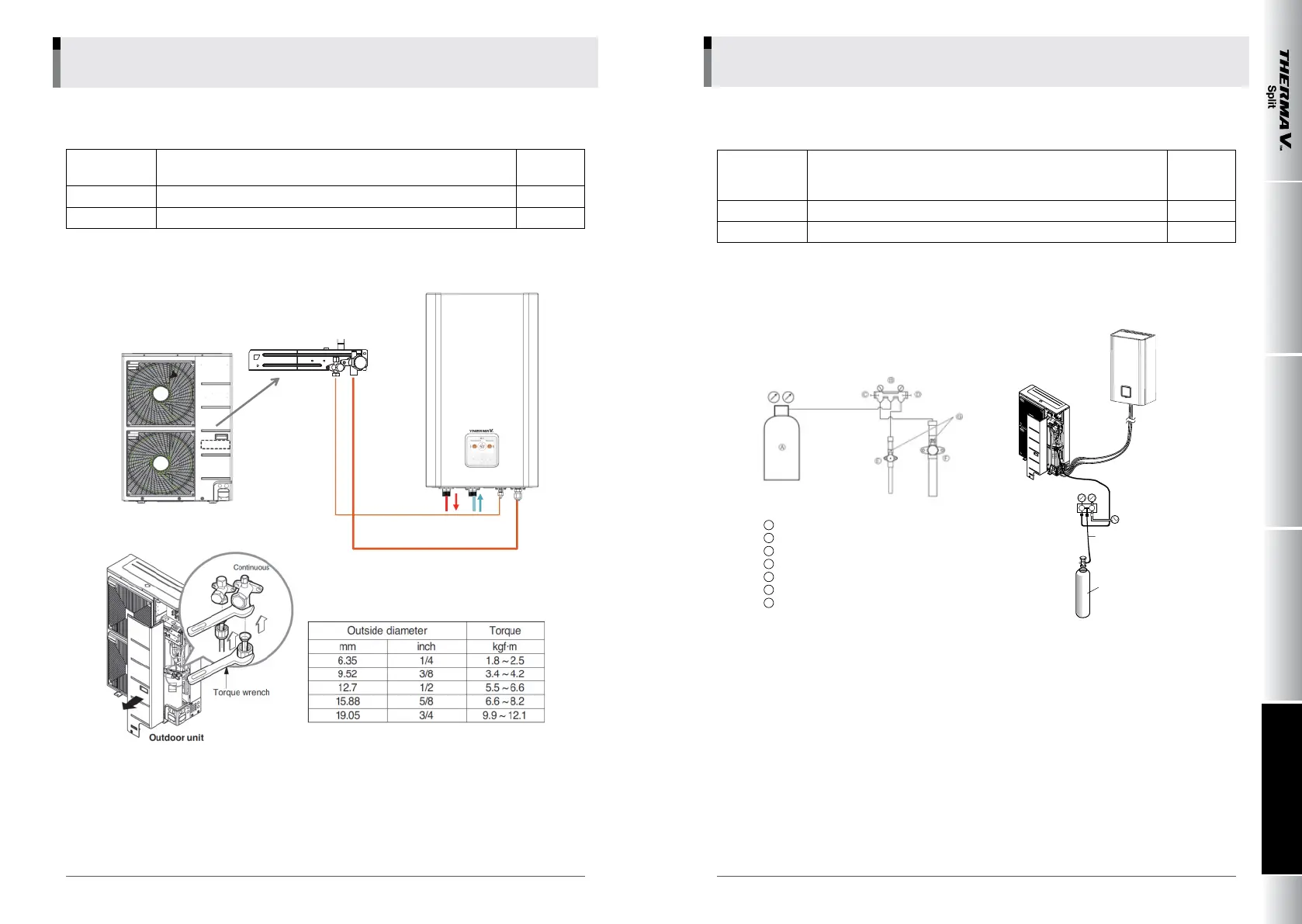

1.1 Piping installation

Items to check

Are pipings correctly connected?

(Water piping, refrigerant piping)

Result

Purpose Check piping connection

Applicants AWHP SPLIT

Check in/outow of water piping connections

Check connections of refrigerant piping and gas/liquid piping

Liquid-Refrigerant

(9.52 mm)

Gas - Refrigerant(15.88 mm)

[Tightening]

In-Water (PT)

1)

Out-Water

(PT 1)

[Supporter]

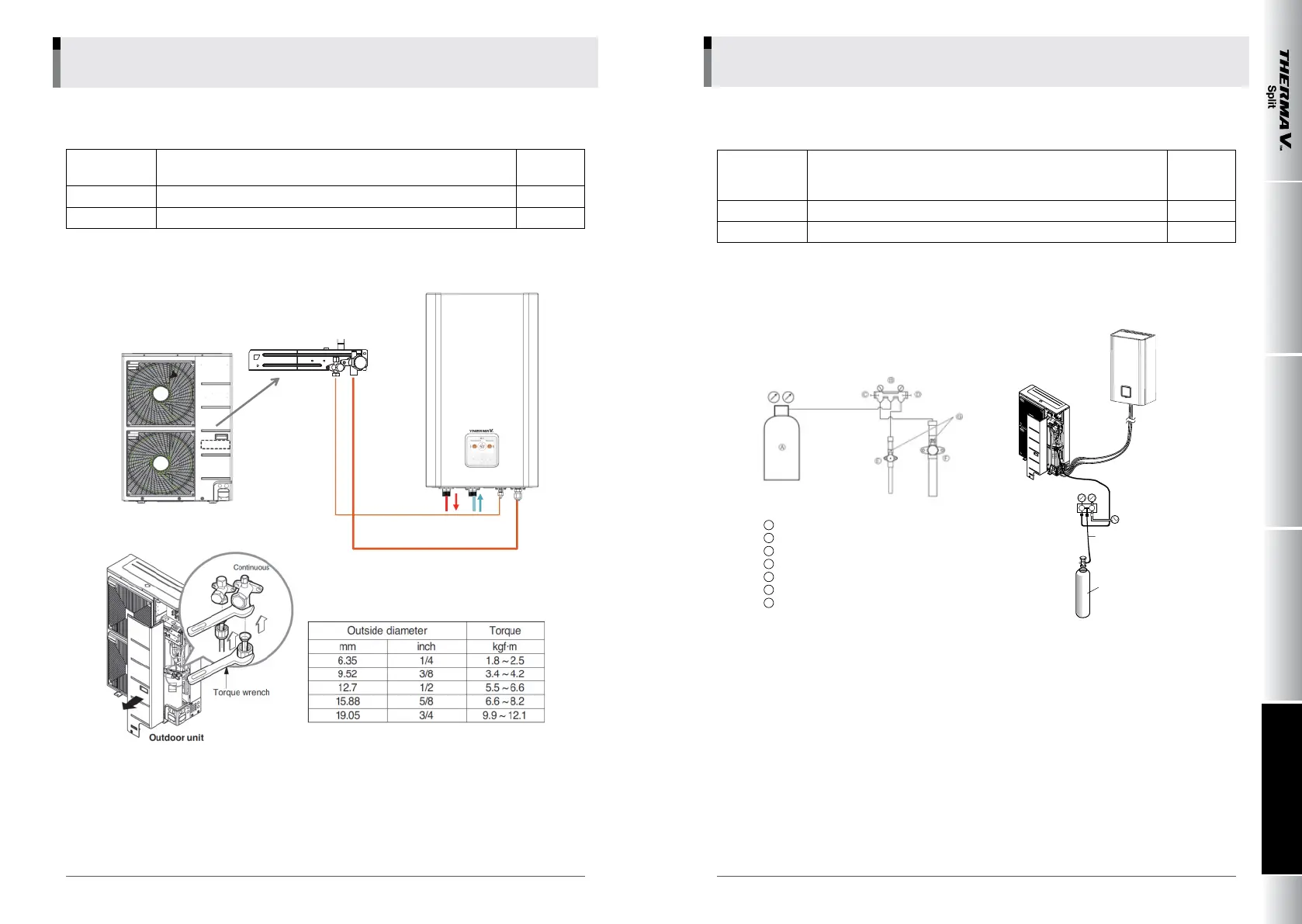

1.2 Leakage test

Items to check

Was the standard airtight test run to check if there is any leakage from

pipings and the product?

(For R410A: 24-hour test with nitrogen pressure of 38 kg)

Result

Purpose Check for leakage on pipings

Applicants AWHP SPLIT

Connect the manifold valve(with pressure gauges) and dry nitrogen gas cylinder to this service port with

charge hoses.

Charge hose

Outdoor unit

Manifold valve

Lo Hi

Pressure

gauge

Nitrogen gas

cylinder(in vertical

standing position)

A Nitrogen gas

B Manifold gauge

C Low pressure cover

D High pressure cover

E Liquid pipe

F Gas pipe

G Service port

Indoor unit

Be sure to use a manifold valve for leakage test.

If it is not available, use a stop valve for this purpose.

The "Hi" knob of the manifold valve must always be kept close.

• Pressurize the system to no more than 3.0 Mpa with dry nitrogen gas and close the cylinder valve when

the gauge reading reaches 3.0 Mpa Next, test for leaks with liquid soap.

After the system is found to be free of leaks, relieve the nitrogen pressure by loosening the charge hose

connector at the nitrogen cylinder. When the system pressure is reduced to normal, disconnect the

hose fromthe cylinder.

Loading...

Loading...