056 057

_

COMPREHENSIVE APPLICATION AND INSTALLATION MANUAL

LG Electronics

Installation check listConguration

System Design ApplicationsIntroduction

• Make sure to conrm that all items in the checklist below after installing the product are OK.

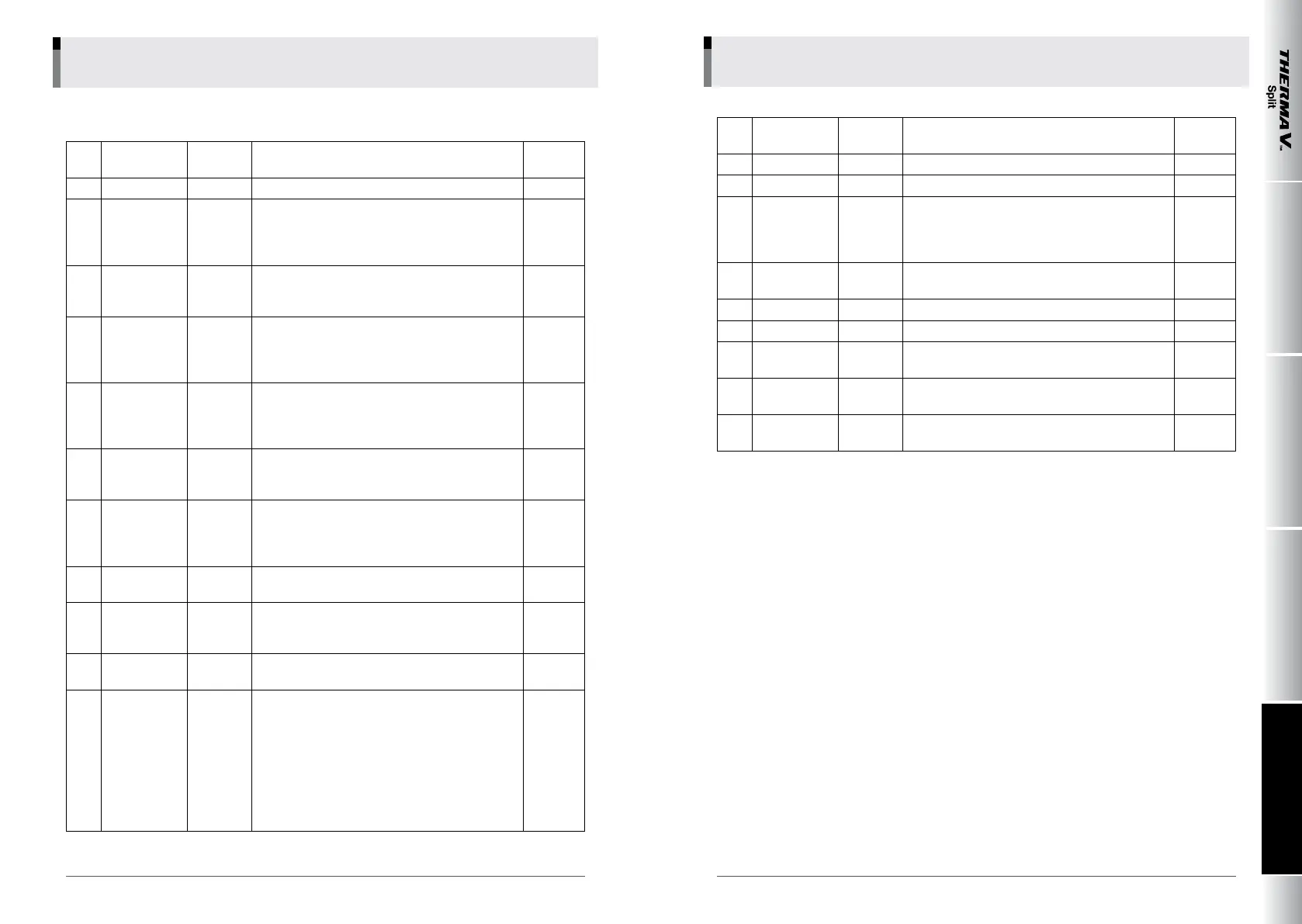

No Category Product Contents

Check

(OK/NO)

1 Installation Split Are pipings correctly connected?

2 Refrigerant Split

Was the standard airtight test run to check if there is

any leakage from pipings and the product?

(For R410A: 24-hour test with nitrogen pressure of

38 kg)

3 Refrigerant Split

Is vacuum level kept at or below 0.5 torr or is there

any change with vacuum for 1 hour after stopping

the vacuum pump?

4 Refrigerant Split

Was the additional amount of refrigerant correctly

calculated based on the length of added piping and

was the weight of refrigerant measured correctly

with an electronic scale before injection?

5 Refrigerant Split

Is there any leakage after connecting the refrigerant

pipings?

Check gas detector and use soap bubbles to nd

any leakage.

6 Installation Split

Is the indoor unit installed in the building and is

it installed and xed according to the installation

manual?

7 Installation Common

Is it possible to secure appropriate service area for

the indoor unit?

(More than 600 mm to the front and 400 mm to

sides)

8 Installation Common

Is the outdoor unit installed and xed rmly?

Wooden pallet removed and xed with anchor.

9 Installation Common

Is the outdoor unit installed at an appropriate loca

-

tion? (Consider air ow, noise and being under the

eaves and etc.)

10 Electric Common

Is there a proper protective measure or earthing

against lightning?

11 Electric Common

Is capacity of power lines and circuit breaker se

-

lected based on the latest catalogue of LG Electron-

ics and is pull-in power for both indoor and outdoor

units normal?

(Power/control cables, earth leakage breaker)

3-phase 4-wire AC 380 V for general purpose /

3-phase 3-wire AC 380 V for factories

Check pull-in power for the indoor unit

(1-phase 2-wire AC 220 V)

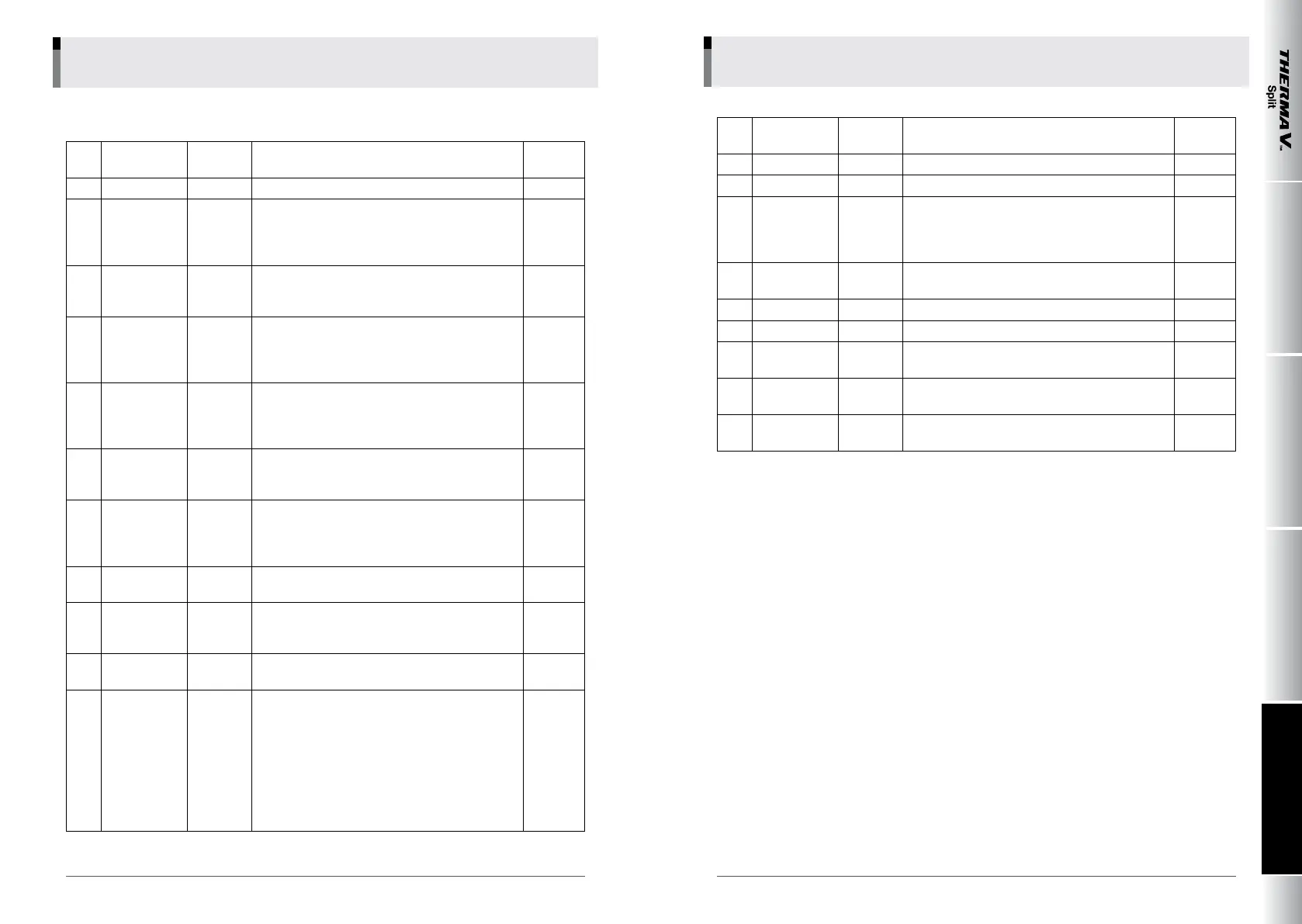

No Category Product Contents

Check

(OK/NO)

12 Water piping Common Is it proper to design the pipe diameter?

13 Water piping Common Is the quality of heat source water acceptable?

14 Water piping Common

Is there an appropriate measure against freezing

and bursting of at heat exchanger in winter?

(Use antifreeze solution or operate either pumps or

auxiliary heater)

15 Water piping Common

Is water lled in the system?

Is water piping pressure at the appropriate level?

16 Water piping Common Is it ushed?

17 Water piping Common Is the magnetic type strainer installed?

18 Water piping Common

Is there any leakage from water piping?

(Check with visual inspection)

19 Water piping Common

Is air vent valve installed and opened at the angled

part of water piping?

20 Water piping Common

Are buffer tank and auxiliary pump installed?

(Option)

1. Checklist

Loading...

Loading...