SMB/SB Installation and Maintenance Manual 140-11000 • July 2003

6.3 Lubrication

Proper lubrication is essential to achieve the actuator design life. The actuator has been designed to minimize maintenance and

relubrication requirements. However, periodic inspection is a necessity.

The SMB and SB actuators have a totally sealed gear case, factory-lubricated with grease. The gear case can be mounted in any

position. However, those mounting positions that would result in the actuator motor being saturated with lubricant if the seal failed

should be avoided and are not recommended.

No seal can remain absolutely tight at all times. Therefore, it is not unusual to find a very small amount of weeping around shaft

seals—especially during long periods of idleness such as storage. Grease lubrication minimizes this condition as much as possible. If

a small amount is weeping at start-up, remove it with a clean cloth. Once the equipment is operating on a regular basis, the weeping

should stop.

6.3.1 Lubrication Inspection

Inspect Limitorque SMB and SB actuators for correct lubrication prior to operating—particularly following a long storage period.

Each application has its own effect on the actuator and the frequency of these inspections should be based on the application and

the operating experience. The following lubrication inspection schedule is recommended until operating experience indicates

otherwise.

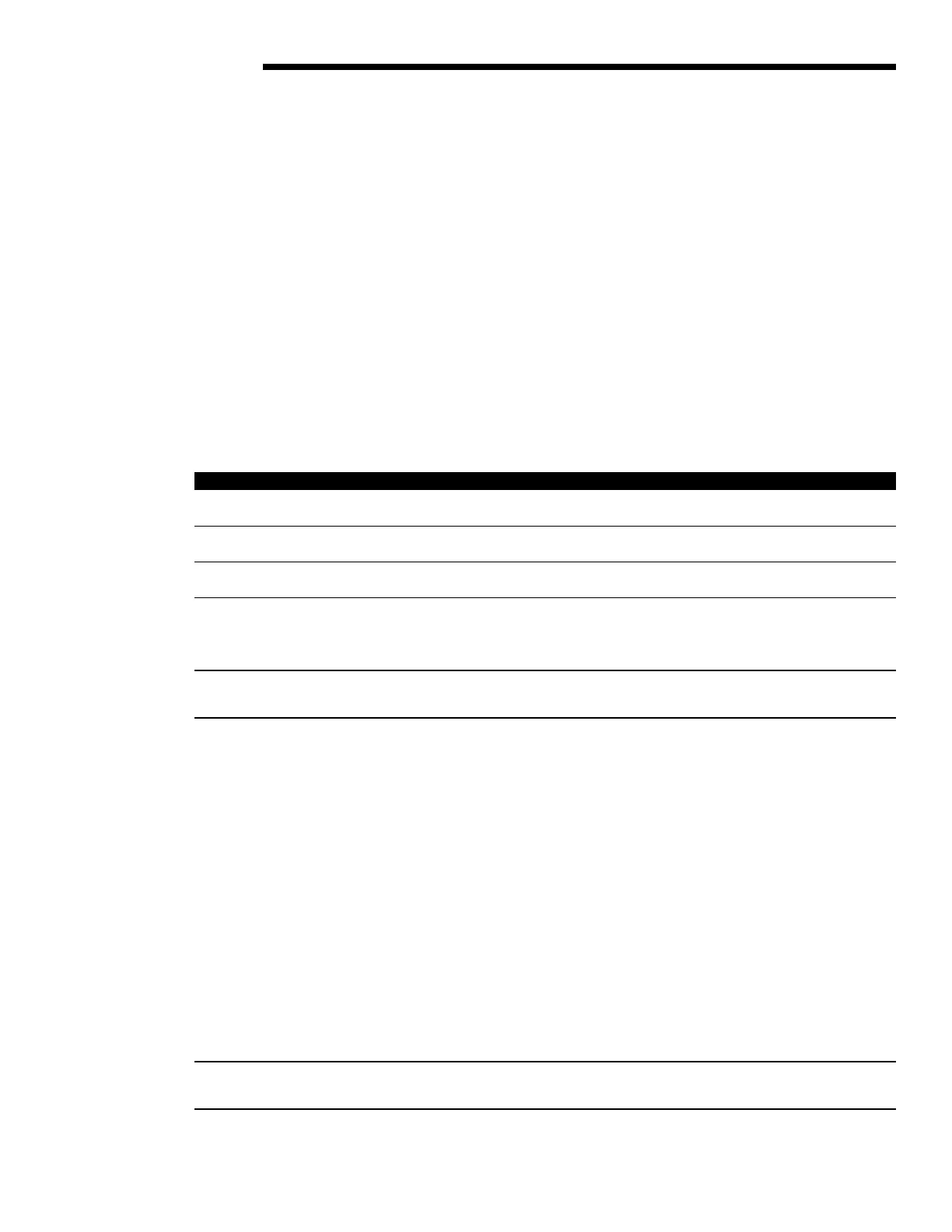

Application Lubrication Recommendations

Main Gear Case Inspect lubrication every 18 months or 500 cycles

– whichever occurs first.

Geared Limit Switch Inspect lubrication every 36 months or 1000 cycles

– whichever occurs first.

Drive Sleeve Top Bearing Lubricate every 6 months through

housing cover pressure fitting.

During an inspection, consider the following:

• Quantity—SMB and SB actuators are built to operate on the immersion principle.

CAUTION:

Ensure there is enough lubricant so that the Worm and the Worm Gear are totally immersed in grease regardless of

the position. Use the “fill” and “drain” plugs provided on the actuator housing to verify this.

• Quality—Inspect lubricant for dirt, water, or foreign matter. If any of these are found:

1. Flush the actuator with a commercial degreaser/cleaner such as Exxon Varsol #18. This degreaser/cleaner is not corrosive

and does not affect the seal materials.

2. Repack the actuator with fresh lubricant, allowing room for thermal expansion of the grease.

• Consistency—Ensure the lubricant is fluid, approximating a standard NLGI-0 grade consistency or less. Thinners such as Amoco

WAYTAC #31 oil may be added provided the volume of thinner does not exceed 20% of the total lubricant volume.

6.3.2 Standard Lubricant

• The SMB/SSB actuator gear case is factory lubricated with an NLGI Grade 0 calcium sulfonate base grease suitable for

temperatures from -20˚F (-29˚C) to 150˚F (66˚C).

Note 1: For nuclear containment actuators, Exxon Nebula EP-0 and EP-1, or Crompton MOV-Long Life, Grade 0 are the only

approved lubricants for SMB-000 through 5.

• Geared Limit Switch: Mobil 28.

• Motor Bearings: Motors furnished for Limitorque actuators are lubricated for life.

• Temperature rating is -20˚F to 150˚F (-29˚C to 66˚C).

NOTE: SMB/SB/SBD-000,00 standard lubricant was Sun Oil Co. (XC-421-39) for serial numbers up to 295809. Sun 50EP (XC-421-39)

can not be mixed with Calcium Complex EP-O.

6-2

Flow Control Division

Limitorque Actuation Systems

Loading...

Loading...