This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

Technical Manual

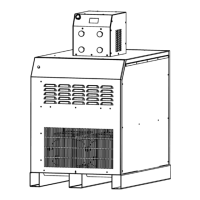

SPIRIT II 400

Register your equipment:

www.lincolnelectric.com/register

Save for future reference

Date Purchased:

Model Number:

Serial Number:

THE LINCOLN ELECTRIC COMPANY

BK8053-000095 Rev C |

Issue Date: 23-May-2018 4130 Carolina Commerce Pkwy Ladson, SC 29456 U.S.A.

© Lincoln Global, Inc. All Rights Reserved Phone: +1.843.695.4000 www.lincolnelectric.com

Manual Plasma Cutting System

with FineLine High Definition Technology