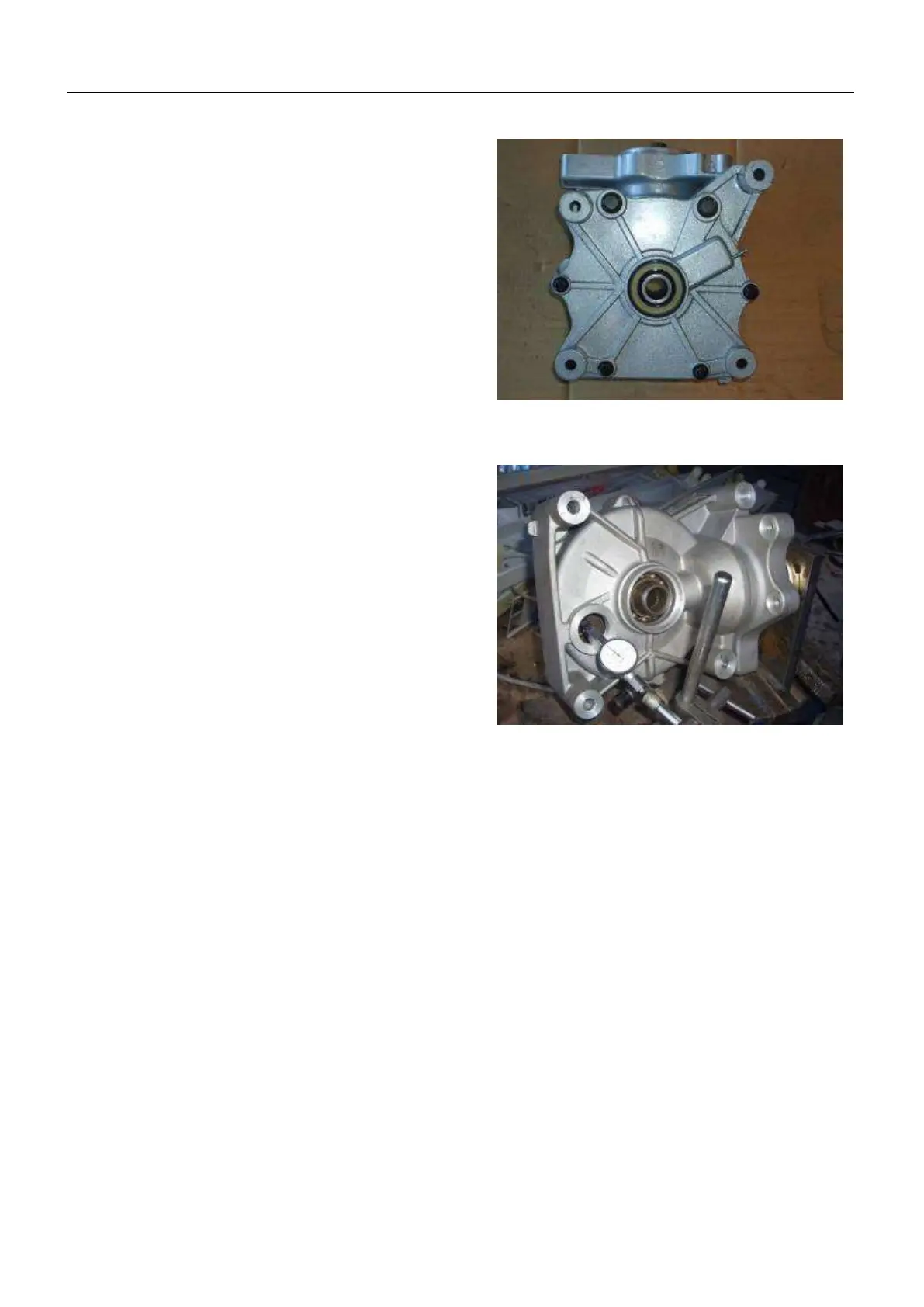

9. Install the cover bolts and tighten them in

several steps until the cover evenly touches

the drive housing. Then while rotating the

pinion gear, tighten the bolts to the specified

torque in a crisscross pattern in several

steps.

TORQUE:

10mm bolt:45N.m

8mm bolt: 25N.m

10. Check that the gear assembly turns

smoothly without binding.

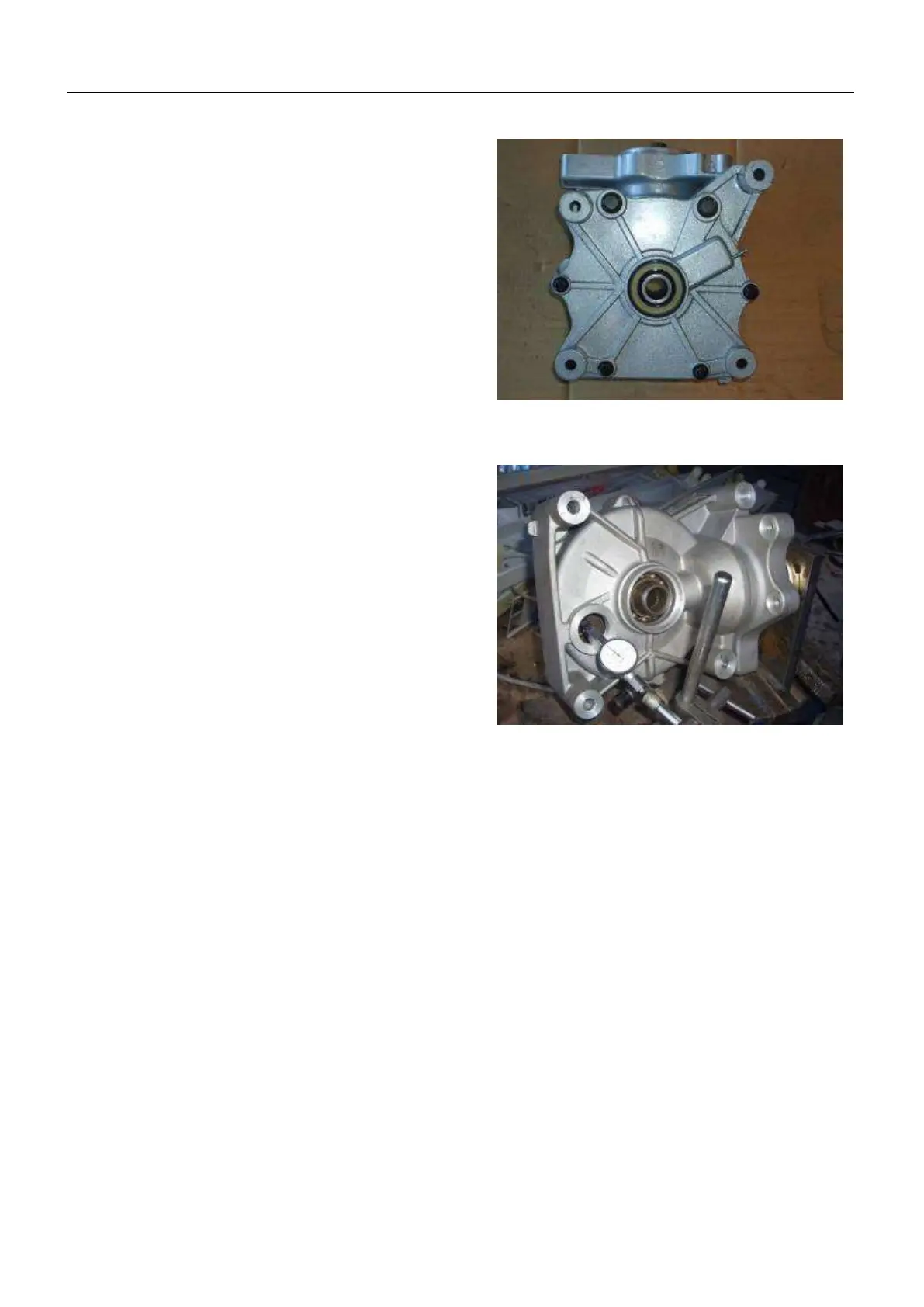

Remove the oil filler cap.

Install the special tool into the pinion joint, and set

the final drive assembly and tool in a vise.

Install the drive shaft into the final drive assembly

and hold it.

Set a horizontal type dial indicator on the ring gear

through the filler hole.

Turn the ring gear back and forth with the drive

shaft to read backlash.

STANDARD:0.05-0.25mm

SERVICE LIMIT:0.4mm

Remove the dial indicator. Turn the ring gear 120°

and measure backlash.

Repeat this procedure once more.

Compare the difference of the three

measurements.

SERVICE LIMIT:0.2mm

If the difference in measurements exceeds the

service limit, it indicates that the bearing is not

installed squarely, or the case is deformed.

Inspect the bearings and case.

If the backlash is excessive, replace the ring gear

right shim with a thinner one.

If the backlash is small, replace the ring gear right

shim with a thicker one.

Backlash is changed by about 0.06mm when

thickness of the spacer is changed by 0.12mm.

Loading...

Loading...