INSPECTION

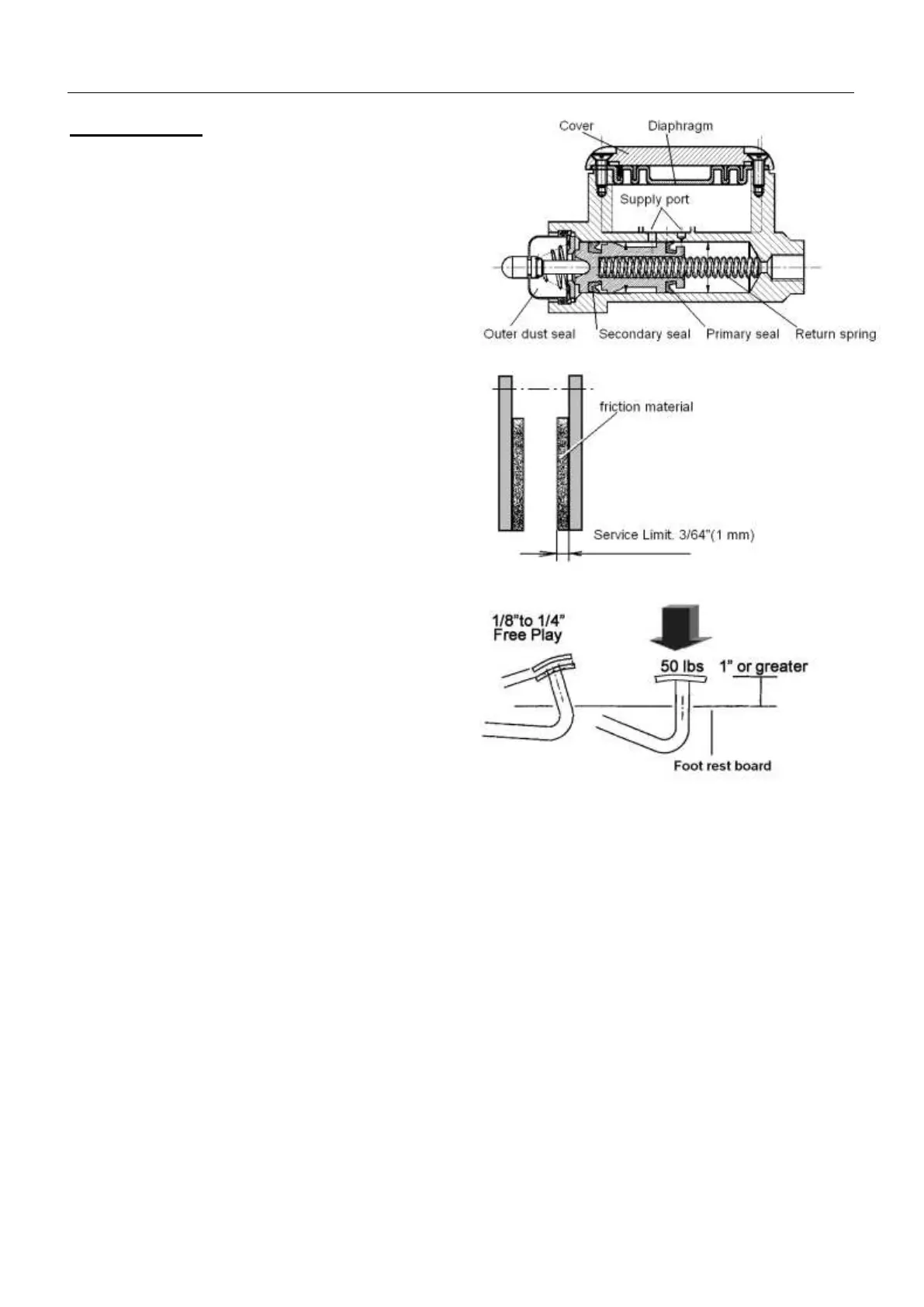

Adjusting brake pedal

1. First check foot brake effectiveness by

applying a 25 kg (50 lb). (Approx)

downward force on the pedal.

The top of the pedal should be at least 1

inch, (25 .4m m) above the surface of the

footrest.

The following checks are recommended to

keep the braking system in good operating

condition. Service life of braking system

components depends on operating conditions.

Inspect brakes in accordance with the

maintenance schedule and before each ride.

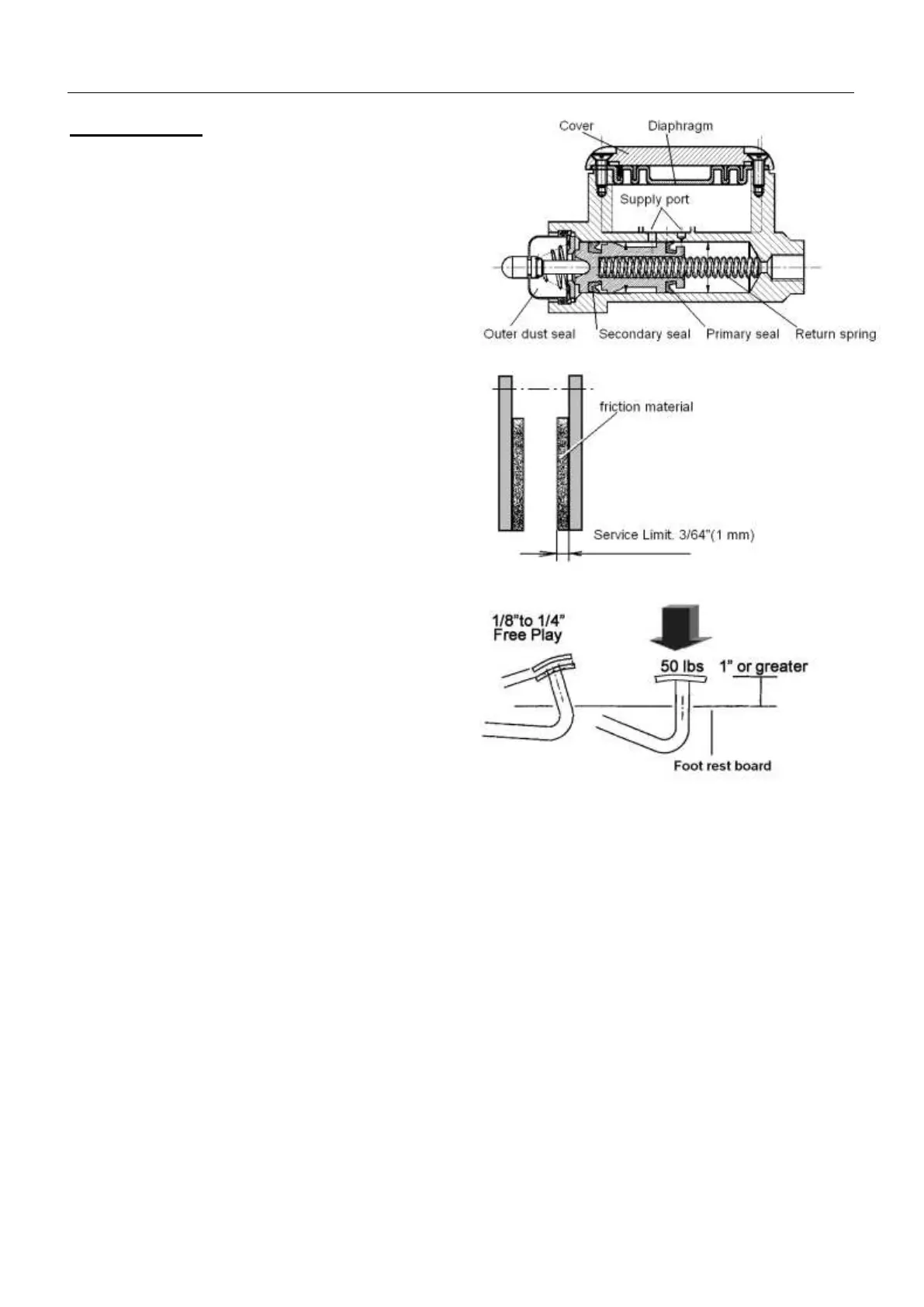

⚫Keep fluid level in the master cylinder

reservoir to the indicated level on reservoir.

⚫Use DOT 3 brake fluid.

NOTE: Use new brake fluid or brake fluid

from a sealed container to avoid

contamination to system.

⚫Check brake system for fluid leaks.

⚫Check brake for excessive travel or spongy

feel.

⚫Check friction pads for wear, damage and

looseness.

⚫Check surface condition of the disc.

BRAKE PAD INSPECTION

⚫Pads should be changed when friction

material is worn to 3/64" (1mm).

HOSE/FITTING INSPECTION

Check braking system hoses and fittings for

cracks, deterioration, abrasion, and leaks.

Tighten any loose fittings and replace any

worn or damaged parts.

FOOT BRAKE ADJUSTMENT

NOTE

On European ATV foot brake is the SERVICE

brake (MAIN brake)

Use the following procedure to inspect the

hydraulic foot brake system and adjust or

bleed if necessary.

If the push rod joint is reinstalled, adjust the

push rod length so that the distance between

the centers of the master cylinder lower

mounting bolt hole and joint pin hole is

80±1mm.After adjustment, tighten the joint

nut.

Loading...

Loading...