Page 16 of 23 FA69350–2 English

Jun 2013

23

How To Create a Production Schedule

Linx 7900

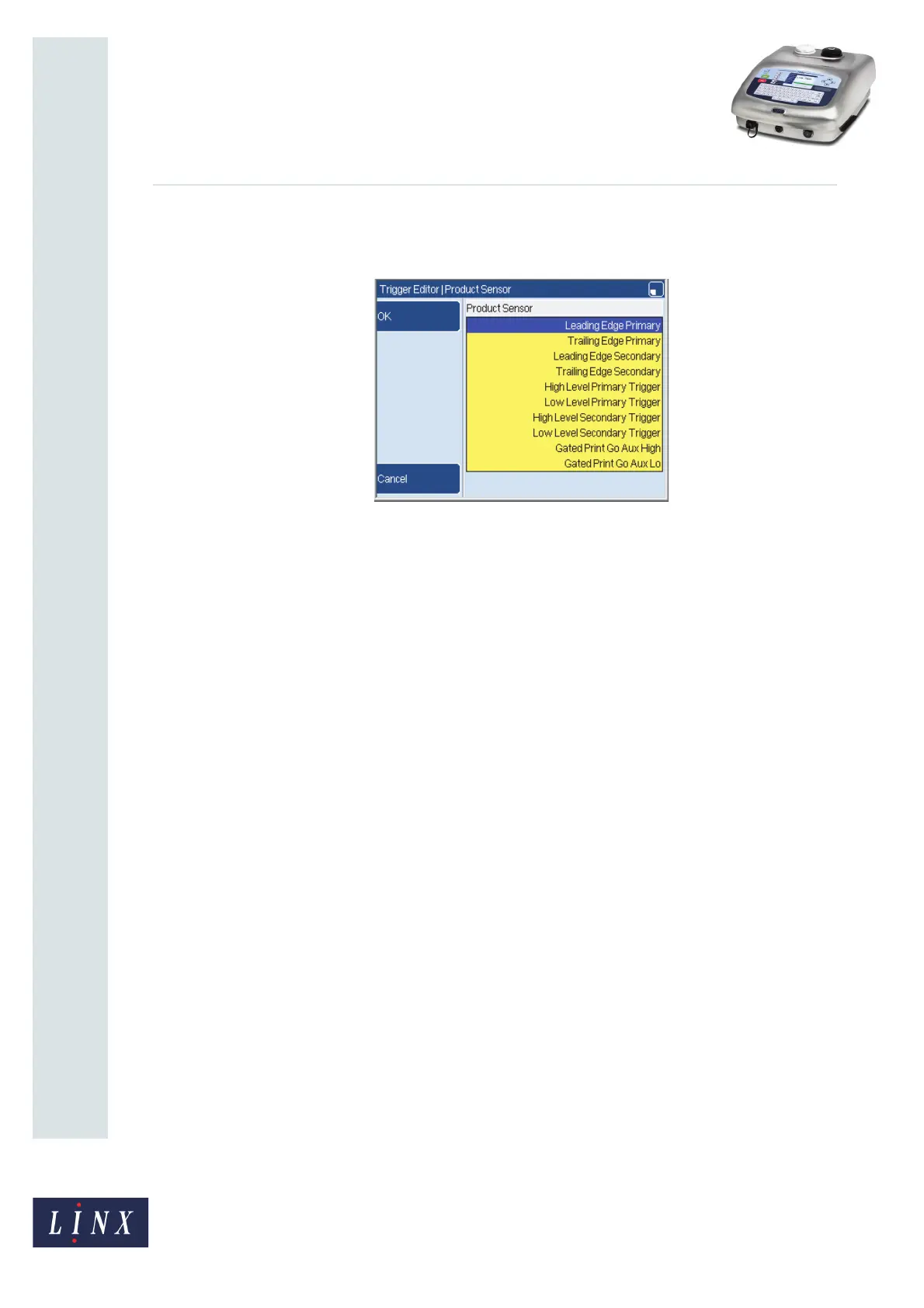

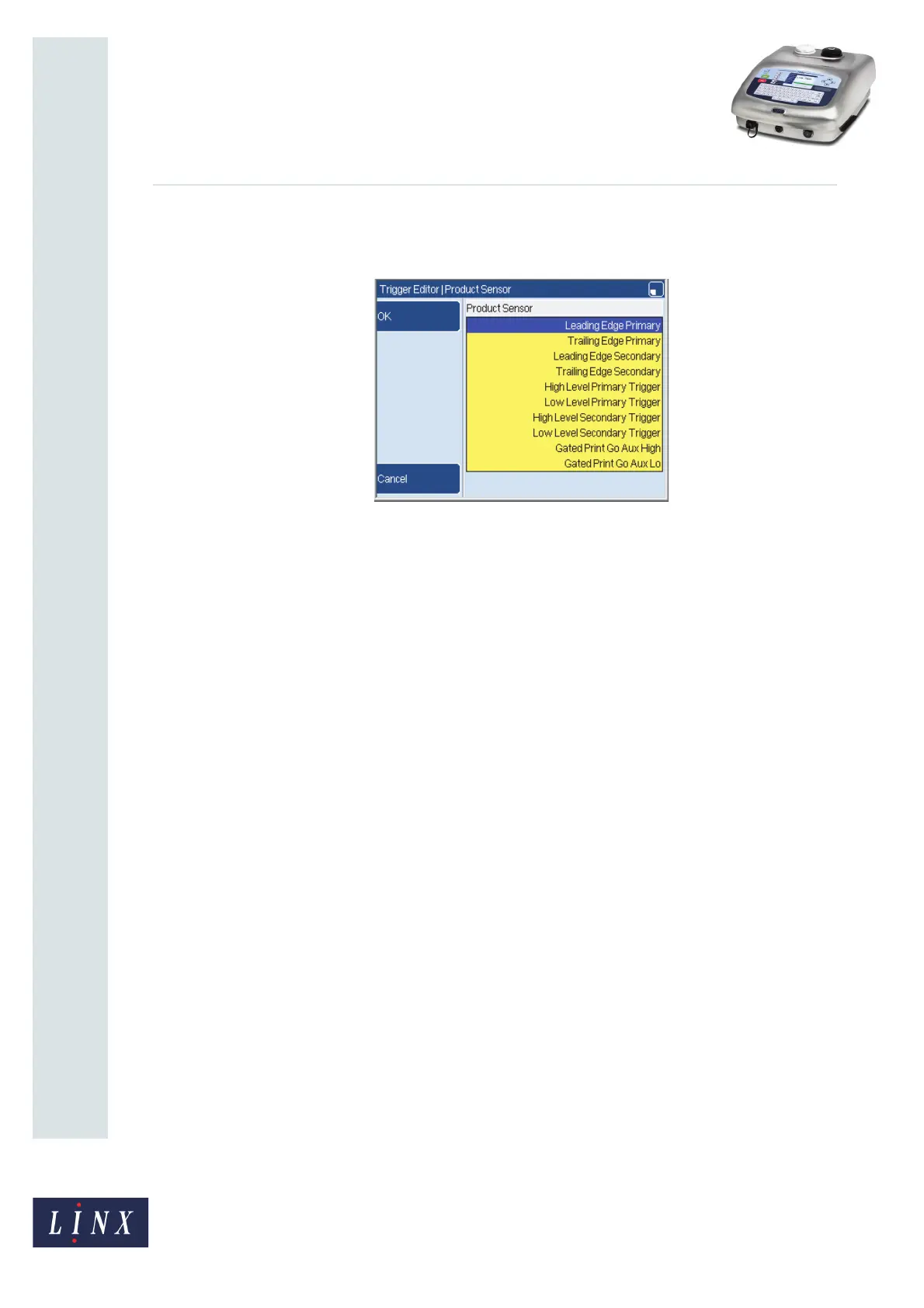

Product Sensor

Use the Product Sensor option to select the product sensor setup that you use.

Figure 19. Trigger Editor: Product Sensor page

Leading Edge Primary

The printer updates the production schedule counter when the primary product sensor

detects the leading edge of a product.

Trailing Edge Primary

The printer updates the production schedule counter when the primary product sensor

detects the trailing edge of the product.

Leading Edge Secondary

The printer updates the production schedule counter when the secondary product sensor

detects the leading edge of a product.

Trailing Edge Secondary

The printer updates the production schedule counter when the secondary product sensor

detects the trailing edge of the product.

High Level Primary Trigger or High Level Secondary Trigger

The printer continuously prints or updates the message while the product sensor detects

the presence of a product (the signal is active).

Low Level Primary Trigger or Low Level Secondary Trigger

The printer continuously prints or updates the message while the printer does not detect the

presence of a product (the signal is not active).

Gated Auxiliary Input Triggers

You can use an auxiliary input (the Secondary Trigger input) to control the operation of a

production schedule. The example in Figure 20 on page 17 shows the current state of the

production schedule counter: N, N+1, N+2... The ‘Print Go’ signal is the signal that starts

each print.

Loading...

Loading...