START UP MANUAL 11

QUICK LOAD SERVO S2

4. MECHANICAL SETTINGS AND OPTIONAL ACCESSORIES

4.1 Feeding pusher

Three feeding pushers are necessary to cover the entire range of the Quick Load Servo S2

bar feed system. Each pusher has a range of operation :

Pusher diameter

Ordering Nr

Diameter Range

**6,35 mm (1/4") *021.011.022 / 6 6 mm - 12 mm (1/4" - 1/2")

12 mm (1/2") *021.011.022 / 12 8 mm - 32 mm (>1/3" - 1 1/4")

25 mm (1") *021.011.022 / 25 33 mm - 120 mm (>1 1/4" - 4,7")

* This ordering number corresponds to the complete pusher, with all of the elements

indicated below. When a feeding pusher is ordered for the first time, use this

number.

** 2 extra roller supports, intended to bolster the support of the bars of small

diameter, are furnished with the 6.35 mm diameter pushers. Their placement on

the loading table will be determined by the length of the bars to be loaded.

Replacement :

Bring the loading channel into working

mode position (down position), then place

the bar feed system into the STOP mode

(remote station).

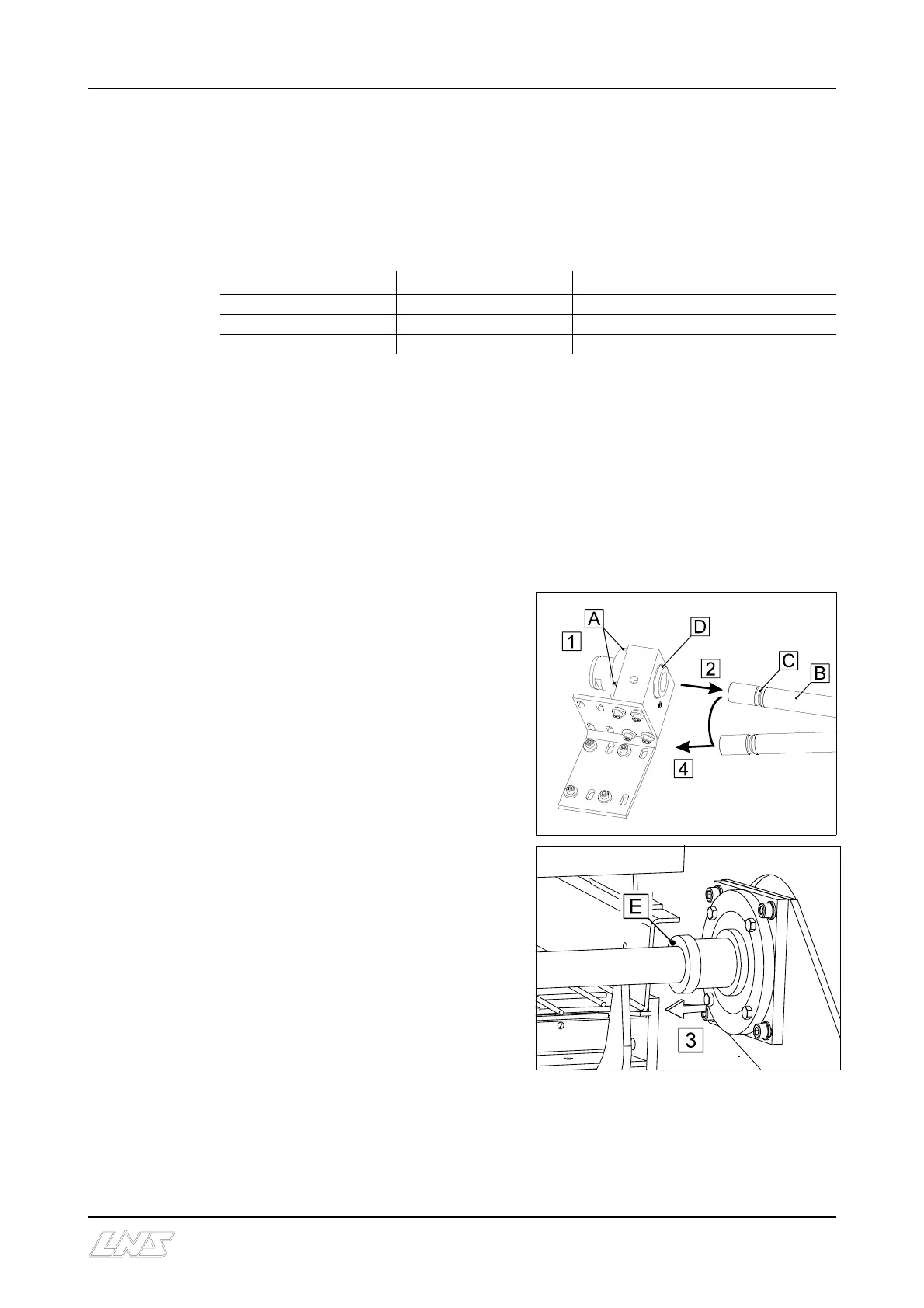

1. Loosen the fastening screws (A)

sufficiently to free the groove (C) that

holds the pusher (B) in the connecting

piece (D).

2. Slide the pusher forward by

making into the guide bushing (E).

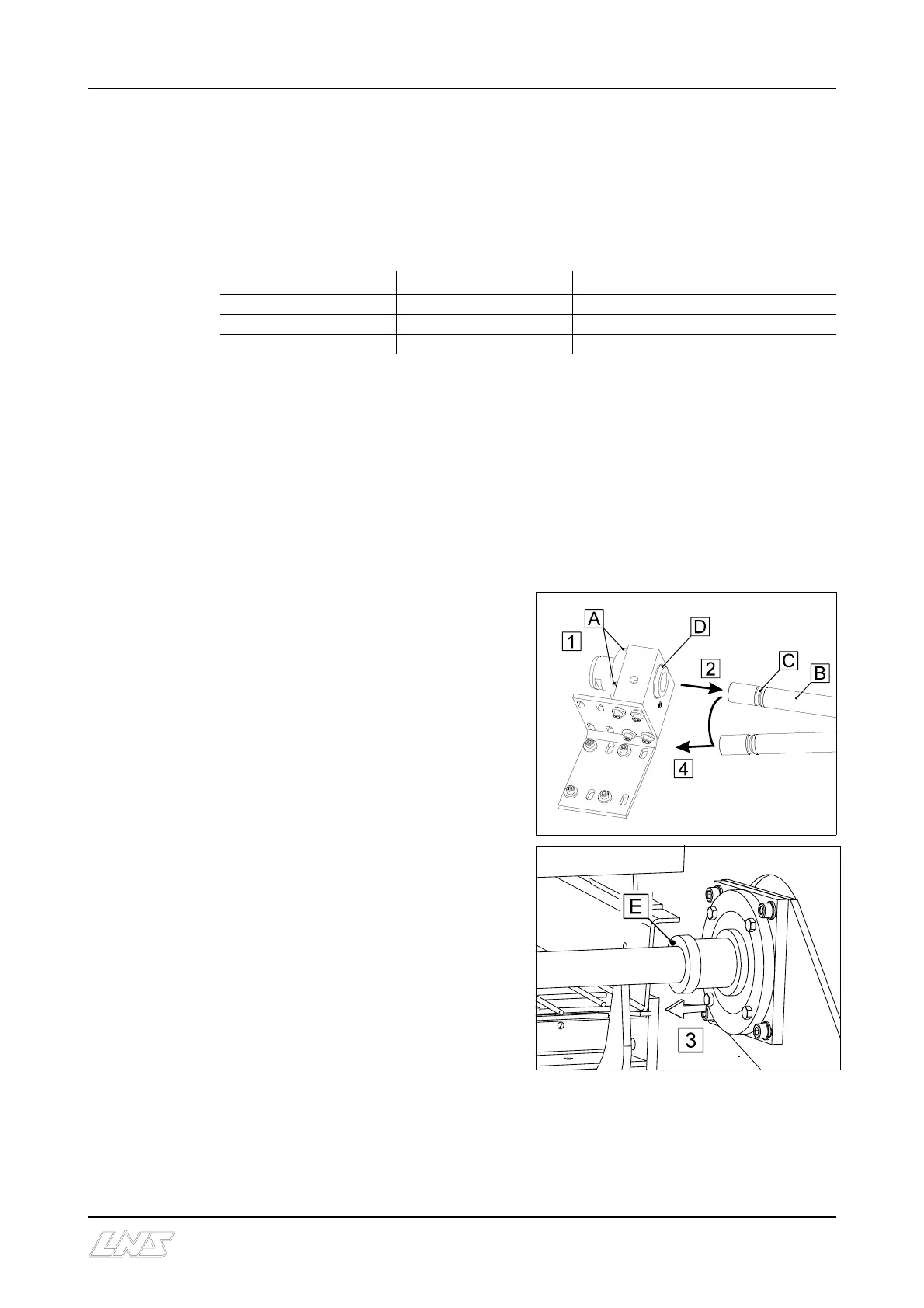

3. When the rear of the pusher is sufficiently

loosened to be able to remove it, pull the

guide bushing (E) toward the back to

dislodge it.

4. The pusher is now free and can be

removed.

• Place the new pusher into the

opening, and insert the guide

bushing.

• Introduce the rear of the pusher

into the connection piece and push

to a stop.

• Tighten the fastening screws so

that they lodge into the groove of

the pusher.

• Check to see the mechanical stop sleeve is properly positioned (see next section)

Loading...

Loading...