14

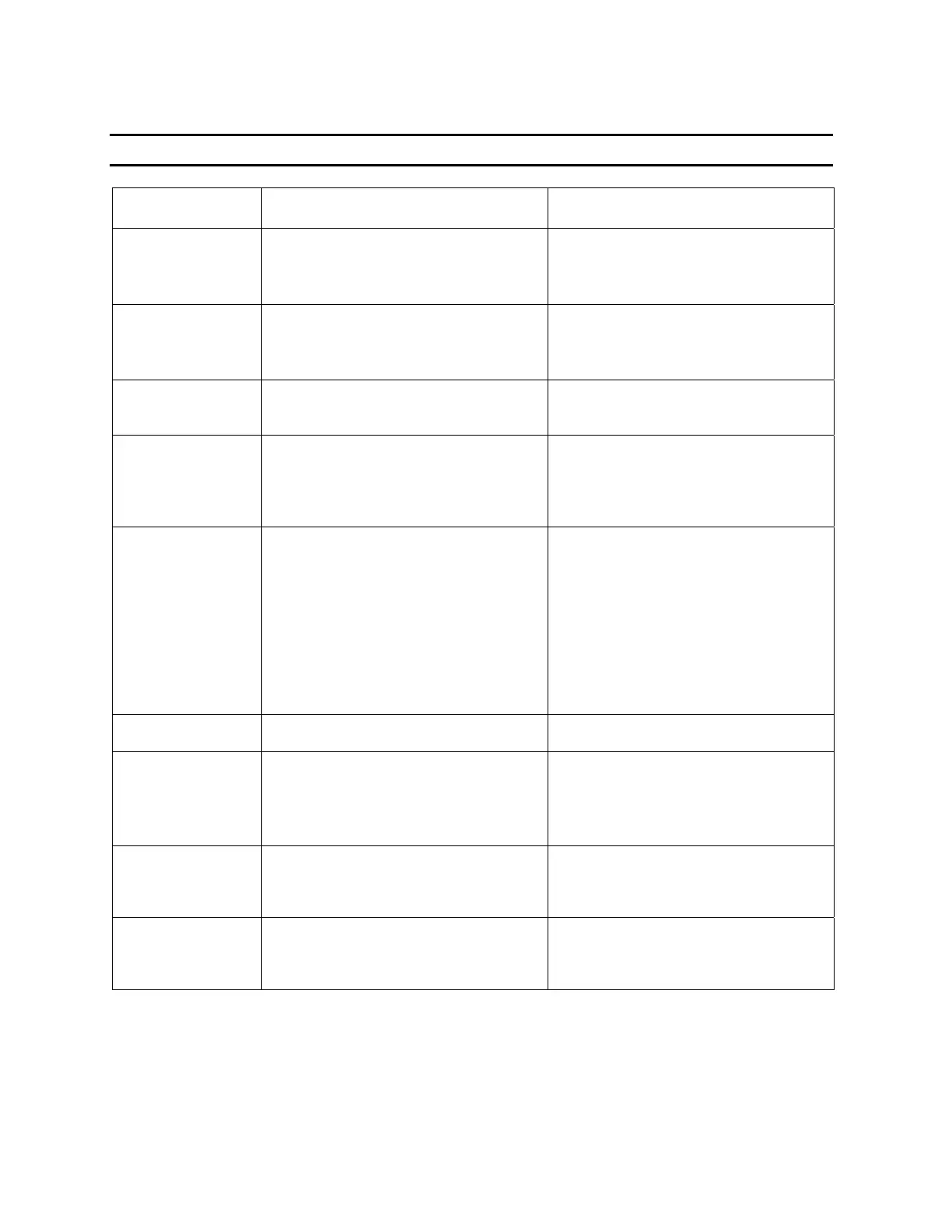

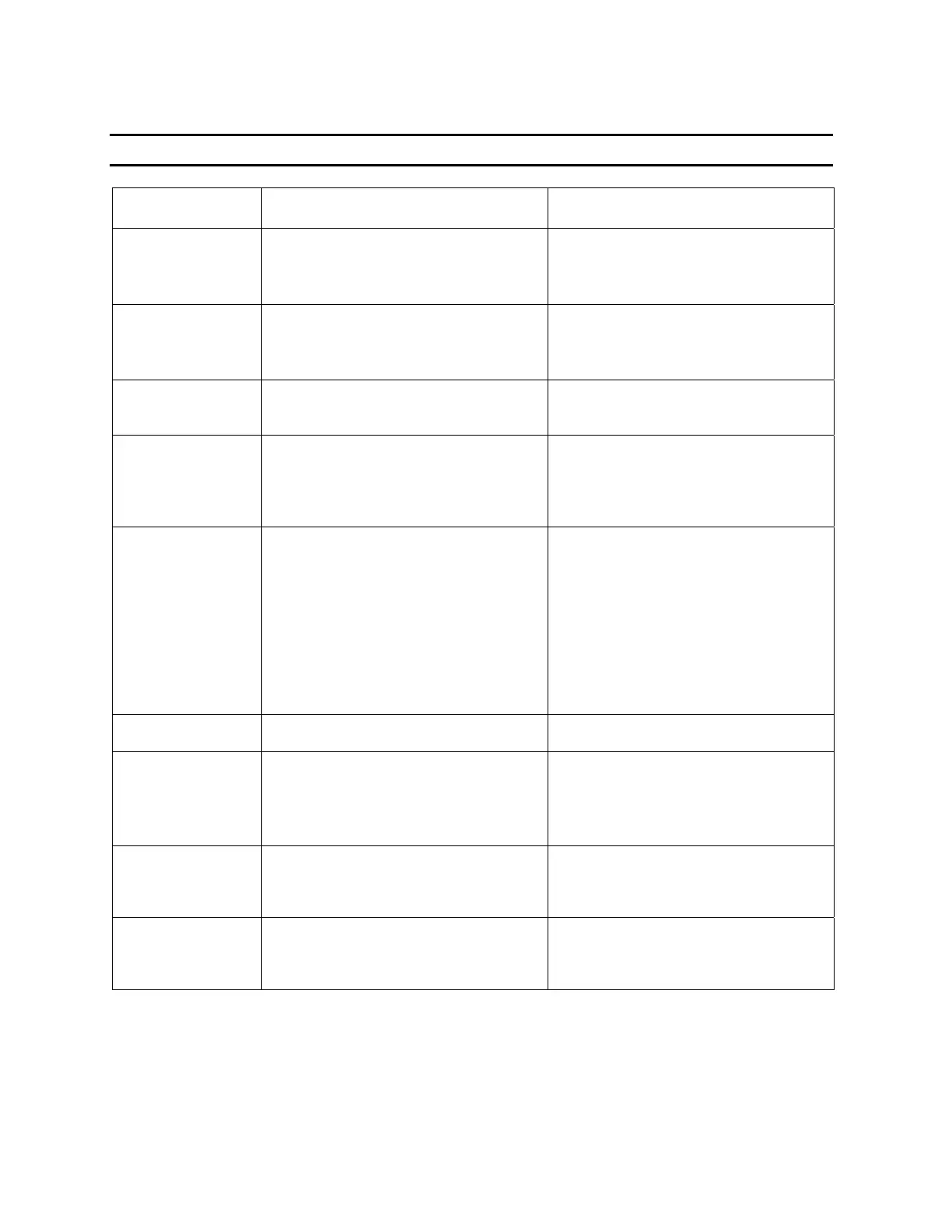

6. Troubleshooting

Symptom Possible Causes Corrections

The digital display

does not light.

- No power voltage present.

- Powers switch 12 in position O (OFF).

- Power adaptor with cord is defective.

- Control unit is defective

Check the power voltage.

Switch power switch to position I (ON).

Replace power adapter with cord.

Call Henkel Service.

No needle movement

on the pressure

gauge.

- No air pressure present.

- Pressure gauge 13 defective.

- Pressure regulator 15 defective.

Check depressurizing valve 14 and

pneumatic supply.

Replace gauge.

Replace regulator.

LED does not light. - LED defect.

When the controller is operational, the unit

can be used until repaired by Henkel

Service.

No start signal. - Plug on the XS1 (20 or 21) : Start 9 is

loose.

- Footswitch defective.

Switch the power switch to the position O

(OFF). Tighten the screws of the plug.

Switch the power switch to the position I

(ON).

Replace the Footswitch.

No product, too little

or too much product.

- Dispensing pressure not set correctly.

- Pressure hose not properly connected.

- Luer-Lock tip cap not removed.

- Dispensing needle clogged, too small or too

large

- Dispensing valve not correctly connected

or defective.

- Product reservoir not switched on.

- Product reservoir is empty.

Adjust dispensing pressure setting.

Connect air pressure hose correctly.

Replace Luer-Lock tip cap with a

dispensing needle.

Replace dispensing needle.

Check the dispensing valve.

Check product reservoir.

Refill product reservoir.

The desired pressure

is not achieved.

- Supply pressure inadequate.

Increase the supply pressure (min 0.5 bar

above reservoir pressure).

Air bubbles in the

product.

- Product reservoir is empty.

- Product hose not correctly connected.

- Dispensing valve not correctly connected

or defective.

- Product reservoir pressure is too high.

Refill product reservoir.

Connect product hose correctly.

Check the dispensing valve (see instruction

manual for dispensing valve).

Lower pressure, longer dispensing time.

Pressurized air

escapes between

reservoir housing

and reservoir lid.

- Reservoir knob is not tightened.

- O-Ring leaky.

Tighten the reservoir knob.

Grease or replace the O-Ring.

Pressurized air

escapes at the

product connection

1.

- Union nut on the product connection not

tightened.

Carefully tighten the union nut.

Loading...

Loading...